Top 4 Features

Hot-dip Galvanised

Zinc layer ≥80 µm for lasting rust protection—no repainting needed.

Laser-Cut Precision

±0.2 mm tolerance ensures tight fit and smooth installation.

Bolt Assembly

No field welding—easier, safer assembly and labor saving.

Custom Dimensions

Fit odd-shaped courts with no extra tooling cost.

Benefit from superior materials and manufacturing processes.

Explore Our EngineeringTechnical Specifications

- Material: Q235 hot-dip galvanized steel

- Main post: 100 × 100 × 3 mm

- Coating: Powder-coated in any RAL color

- Assembly: Bolt-connected, no welding required

- Extras: PDF drawings and QC report downloadable

Get all the technical details you need for your project planning.

Download Full Spec SheetOne Frame, Multiple Solutions

Our unified frame platform supports all models, ensuring consistent quality, unified spare parts, and easier maintenance across your entire facility.

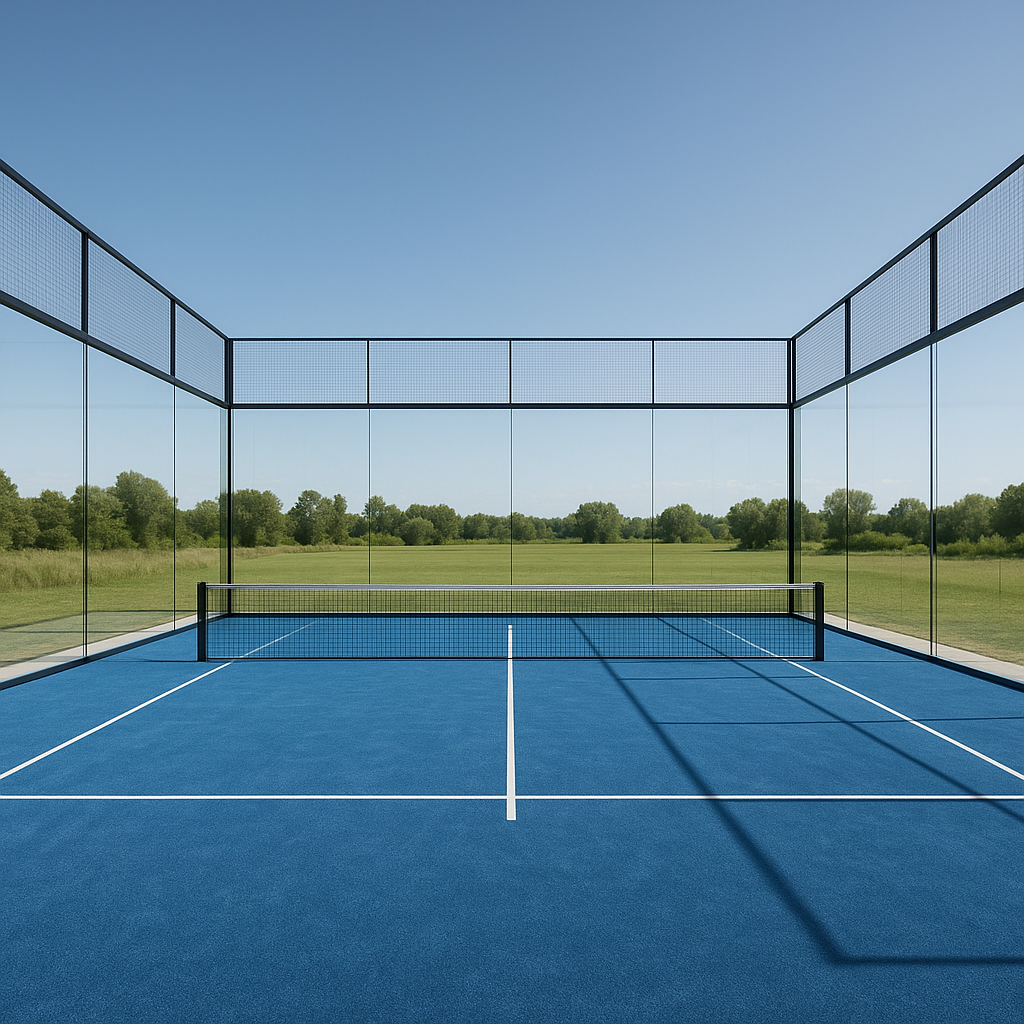

Standard Court

Panoramic Court

Super Panoramic Court

Roofed Court

See how our structures have been implemented in projects worldwide.

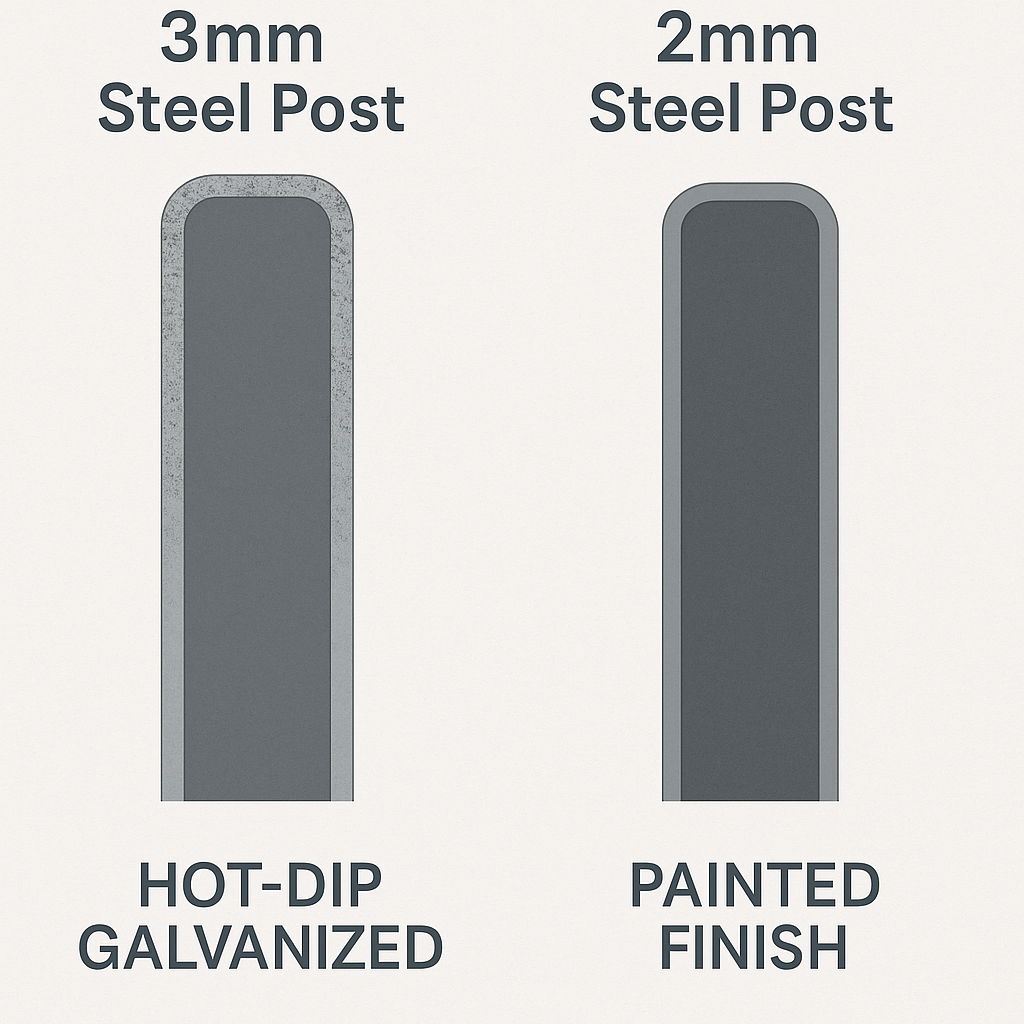

View Our Project GalleryOur Quality vs. The Standard

A higher standard of materials directly translates to a longer lifespan, easier upkeep, and a lower total cost of ownership for your investment.

| Feature | Ours | Others |

|---|---|---|

| Steel Thickness | 3 mm | 2 mm |

| Surface Finish | Full Hot-Dip + Powder Coat | Paint Only |

| Connection | High-Strength Bolts | Spot Welding |

Invest in quality that lasts and reduces long-term costs.

See the DifferenceYour Brand, Your Court

We speed up your project approvals and shorten the build time by providing CAD matching within 48 hours for all your customization needs.

- Color: Choose any color from the RAL chart to match your brand identity.

- Logo: Add your custom logo to the structure for enhanced brand visibility.

- Anchor Plate & Hole Pattern: We modify designs to fit your specific foundation requirements.

Let's build a court that is uniquely yours.

Discuss Your Custom NeedsProduction Timeline

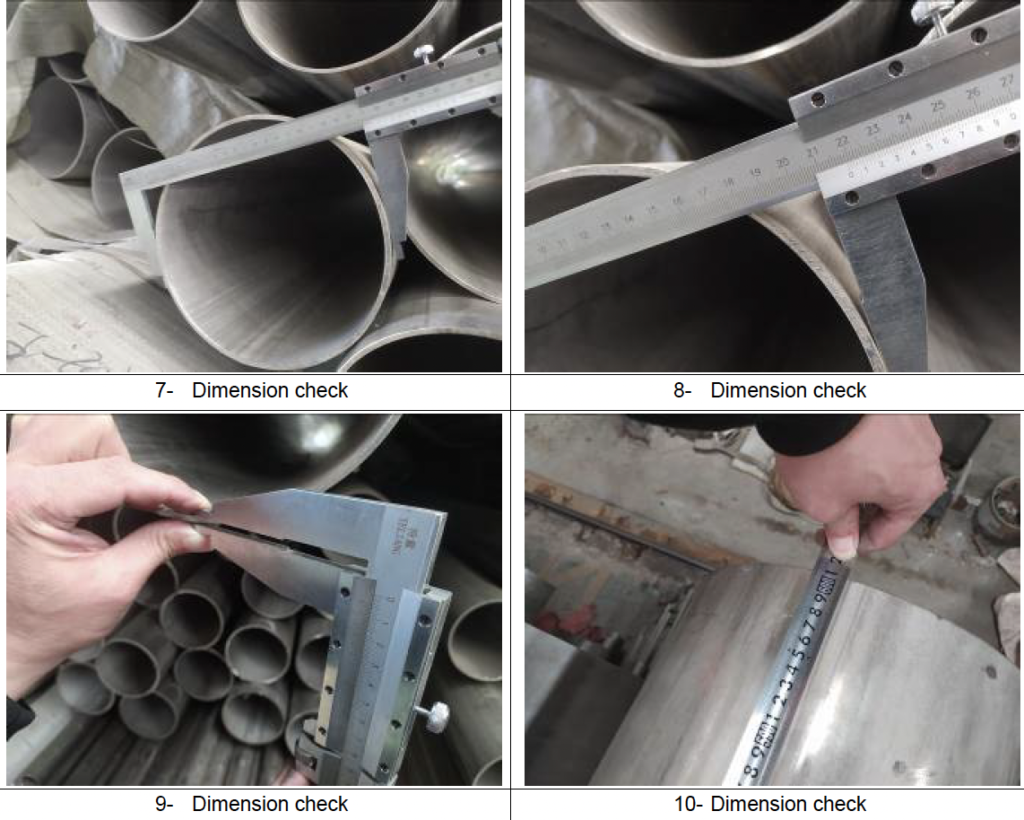

Our streamlined manufacturing process ensures consistent quality and reliable delivery times. Each step is carefully monitored to meet the highest standards for your padel court structures.

Drawing Confirmation

Technical review and approval of CAD drawings, dimensions, and specifications

Cutting & Drilling

Precision laser cutting and drilling with ±0.2mm tolerance for perfect fit

Welding & Polishing

Professional welding and surface polishing to ensure structural integrity

Powder Coating

Hot-dip galvanizing and powder coating for superior corrosion resistance

QC & Packing

Comprehensive quality control inspection and secure packaging for shipment

Why Choose Our Production Process?

Our manufacturing process combines cutting-edge technology with decades of experience to deliver superior padel court structures that exceed industry standards.

- ISO 9001 certified quality management system

- Real-time production tracking and updates

- Comprehensive quality control at every stage

- Dedicated project manager for each order

- Complete documentation and certificates

Trusted by Professionals Worldwide

“Frames arrived scratch-free and installed in 4 hours.”

“30% cost saving compared with local supplier.”

“Hot-dip galvanised finish still perfect after two winters.”

Join our growing list of satisfied global partners.

Become Our Next Success StoryFrequently Asked Questions

Yes, structure-only orders are welcome.

Yes, we provide the full set of high-strength bolts and all necessary assembly hardware with each structure.

Remote technical guidance via video call is included free of charge. On-site supervision is an optional service available upon request.

Our structures are packed securely in a steel rack, wrapped with protective PE film, and reinforced with straps to ensure they arrive in perfect condition.

Our structures are fully hot-dip galvanized for maximum corrosion protection, then finished with a durable powder coating. We do not use inferior spray paint.

Have a different question? Our experts are here to help.

Contact UsGet Your Free CAD Drawings & Official Quote

With a 15–20 day lead time and full support for OEM colour and hole layouts, we are ready to be your direct manufacturing partner. Complete the form to receive a complete quotation and technical package within 24 hours.