Building a professional sports facility requires precise financial planning because finding transparent pricing often feels like a guessing game for new business owners. Here’s the deal. Most professional court setups fluctuate between eighteen thousand and thirty-five thousand dollars depending on structural specifications plus specific logistical requirements for your location. You need a durable solution that withstands heavy usage while maintaining international safety standards for your active players without overspending your budget. Fortunately, our fifteen years of manufacturing excellence provides you with direct factory access to premium components without middleman markups at how much does a padel court cost. By understanding the mechanical components plus assembly phases, you can optimize your investment effectively while ensuring a high-quality experience for everyone.

How much does a padel court cost for basic professional setups?

Most standard hardware kits usually require an initial investment of roughly twenty thousand dollars before you add logistics costs or local labor fees.

Facility owners often find that most setups demand these funds for high-quality components excluding any localized taxes or building permits required by your city. This base price includes galvanized steel frames plus heavy-duty tempered safety glass panels for international compliance during intense matches with high ball velocity impacts. Choosing a factory-direct path ensures your capital goes toward material quality rather than paying expensive middleman markups for identical items from local sports retailers.

What components define a standard kit?

A complete kit includes galvanized steel structures, monofilament synthetic turf, tempered safety glass, and professional-grade net systems for your club members. But wait, there’s more. Lighting systems featuring four two-hundred-watt LED floodlights provide four hundred lux for evening play across your entire playing surface during night sessions. Each panel of twelve-millimeter glass must meet European safety standards to prevent shattering during high-intensity matches where players might collide with the walls. Integrated anchor plates plus stainless steel hardware ensure the structure remains stable against heavy wind loads or seismic activity in your specific region.

- Galvanized Q235 steel frame

- 12mm tempered safety glass

- Monofilament artificial grass turf

- LED floodlights with IP67 rating

Why does structural steel quality matter?

Structural longevity depends heavily on the galvanization process used during the manufacturing phase of your specific court components for long-term rust prevention. Ready for the good part? Using hot-dip galvanized Q235 steel provides superior corrosion resistance compared to cheaper cold-sprayed alternatives found in lower-priced market offerings from uncertified vendors. This chemical bonding process creates a protective layer that resists paint peeling for at least five years under harsh weather or coastal environments. Heavy-duty tube walls measuring three millimeters thick prevent bending or warping when players collide with side mesh panels during aggressive defensive plays.

- Hot-dip galvanization technology

- Q235 carbon steel grade

- 3mm structural wall thickness

- Corrosion resistant powder coating

Key Takeaway: A standard professional padel court requires roughly $20,000 for high-quality materials including steel, glass, and turf.

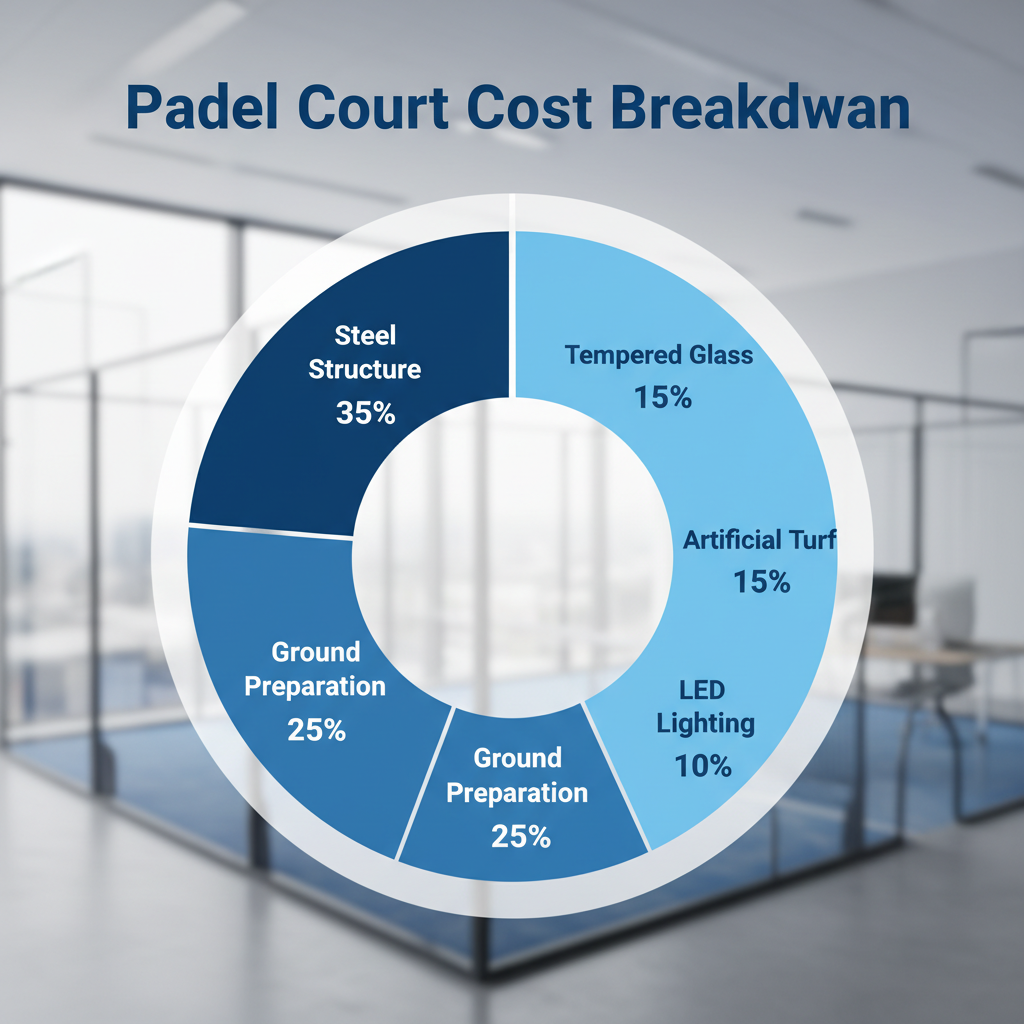

| Component | Specification | Estimated Cost Share |

|---|---|---|

| Steel Frame | Q235 Hot-Dip Galvanized | 45% |

| Safety Glass | 12mm EN 12150 Tempered | 25% |

| Synthetic Turf | 12mm Monofilament | 15% |

| LED Lighting | 4x 200W IP67 | 10% |

| Accessories | Net, Posts, Hardware | 5% |

What materials impact how much does a padel court cost for owners?

Material selection directly dictates how much does a padel court cost because high-performance alloys plus specialized glass treatments carry higher production expenses for manufacturers.

Choosing premium Q235 steel posts that undergo CNC precision cutting ensures every bolt hole aligns perfectly during the final assembly phase on site. While cheaper materials might save money initially, they often lead to frequent maintenance issues like rust or loose glass panels over several years. Superior monofilament grass fibers provide better ball bounce plus player safety than older fibrillated turf options used in lower quality sports facilities. Investing in quality materials reduces the total cost of ownership over a ten-year operational period by minimizing replacement needs for your club.

How does glass thickness affect safety?

Standard twelve-millimeter tempered glass offers necessary impact resistance for competitive play while maintaining a flatness tolerance of zero point two millimeters. What’s the real story? Thinner glass might reduce your upfront price but significantly increases the risk of catastrophic failure during high-velocity ball impacts or player collisions. Polished edges plus precise hole drilling prevent stress fractures from developing at mounting points over time during extreme temperature changes in outdoor settings. Professional safety markings on each panel ensure compliance with local building codes plus insurance requirements for public facilities where liability protection is necessary.

- 12mm tempered safety thickness

- Polished edges for durability

- Flatness tolerance of 0.2mm

- Safety markings for compliance

Does the mesh type influence the price?

Welded mesh panels provide the rigid rebounding surface required for the classic padel experience where the ball remains in play constantly. Here is the deal. Electro-galvanized mesh that receives secondary powder coating offers double protection against oxidation in coastal or high-humidity regions where salt air is common. Reinforced horizontal bars within the mesh frame prevent sagging plus maintain aesthetic appeal for your sports club over many years of usage. Precision-engineered mesh spacing ensures the ball behaves predictably when striking the perimeter during intense rallies between experienced players at your facility.

- 50x50mm mesh spacing grid

- Double coating protection layers

- Reinforced horizontal support bars

- Anti-vibration mounting hardware systems

Key Takeaway: Premium steel and thick glass increase initial price but lower long-term repair expenses significantly for club owners.

| Material | Level | Durability | Cost Impact |

|---|---|---|---|

| Steel | Q235 HDG | 15+ Years | High |

| Glass | 12mm Tempered | High Safety | Medium |

| Coating | Powder Coat | UV Resistant | Low |

How much does a padel court cost when choosing panoramic glass?

Facility owners often ask how much does a padel court cost when they want the sleek look of a panoramic design.

Panoramic models eliminate large corner pillars to provide spectators with an unobstructed view of the action from any stadium angle for tournaments. These premium designs usually carry a price premium of twenty to thirty percent over standard welded mesh configurations due to structural engineering requirements. Specialized twelve-millimeter glass used in these models must be exceptionally strong to support the structure without traditional vertical steel supports at corners. High-end clubs prefer this aesthetic to attract sponsors plus host televised tournament events efficiently while providing a modern atmosphere for all guests.

Why are panoramic views more expensive?

Removing structural posts requires thicker horizontal beams plus reinforced glass panels to maintain same level of wind resistance for outdoor court safety. But here’s the kicker. Each glass panel in a panoramic system acts as a load-bearing element that must withstand intense vibrations from play without cracking over time. Special stainless steel connectors plus hidden anchor systems are utilized to create the invisible frame look desired by luxury resorts or hotels. These engineering requirements increase manufacturing complexity plus the precision needed during factory quality control checks before shipping the kits to your location.

- 12mm load-bearing safety glass

- Reinforced horizontal steel beams

- Hidden anchor plate systems

- Precision stainless steel connectors

Is the spectator experience worth the price?

Investing in panoramic visibility allows your facility to sell more court time by creating a professional atmosphere that players are willing to pay. You might be wondering. Better viewing angles for coaches plus spectators turn a simple sports court into a legitimate entertainment venue for regional competitions or leagues. Sponsors are more likely to fund courts where their branding is visible through clear glass walls without metal obstructions blocking the view. This aesthetic choice often results in a faster return on investment through higher membership fees plus tournament revenue for your growing business.

- 360-degree unobstructed viewing angles

- Professional tournament broadcast capabilities

- Higher premium rental rates

- Increased sponsorship logo visibility

Key Takeaway: Panoramic courts cost 25% more due to reinforced glass and specialized engineering but offer superior visibility.

| Model | View Type | structural support | Price Range |

|---|---|---|---|

| Standard | Partial | 100x100mm Posts | $18k – $22k |

| Panoramic | Full 360 | Hidden Connectors | $24k – $30k |

| Super Panoramic | Tournament | Zero Corner Posts | $32k+ |

Does ground work change how much does a padel court cost greatly?

Site preparation is a major variable when calculating how much does a padel court cost for any new project location worldwide.

You must provide a perfectly level concrete foundation with a minimum thickness of fifteen centimeters to support heavy steel frames plus glass. If your soil is unstable or requires extensive grading, your local construction costs could double before the court kit even arrives on. Proper drainage systems prevent water from pooling under synthetic turf which can ruin adhesive plus playing surface quality for your club members. Always consult with a local civil engineer to verify your specific ground load requirements based on soil density plus local weather patterns.

How thick should the concrete slab be?

A reinforced concrete slab of twenty centimeters is recommended for high-traffic commercial clubs to prevent cracking or shifting over several years of use. Ready for the good part? Using high-strength concrete with smooth finish ensures monofilament turf lays flat without creating dangerous tripping hazards for active players during matches. Proper curing time of at least twenty-one days is necessary before you can bolt the steel frame into ground securely for stability. Integrated expansion joints help the foundation survive temperature fluctuations without damaging structural integrity of padel court walls during extreme winter or summer.

- 15cm minimum slab thickness

- 21-day concrete curing period

- High-strength reinforced material

- Laser-leveled surface finish

Why is drainage a critical expense?

Poor drainage leads to mold growth under turf plus can cause glass panels to misalign if ground shifts from water saturation over time. But that is not all. Installing a slight slope of one percent or dedicated trench system ensures rain clears the playing surface in minutes for fast recovery. This allows your club to remain operational immediately after a storm which maximizes your daily revenue potential during the rainy season or winter. High-quality geotextile layers under the turf can also help manage moisture while providing soft feel for player movement during long matches.

- 1% surface drainage slope

- Perimeter trench system installation

- Geotextile moisture barrier layers

- Rapid play recovery capability

Key Takeaway: Foundation costs often equal 50% of the court kit price and require professional leveling and drainage.

| Foundation Step | Requirement | Purpose | Importance |

|---|---|---|---|

| Excavation | Level Ground | Stability | Critical |

| Concrete Pour | 15cm+ Thick | Load Bearing | High |

| Drainage | 1% Slope | Surface Play | Medium |

How much does a padel court cost with premium LED lighting kits?

Illumination quality significantly alters how much does a padel court cost because high-performance fixtures require specialized drivers plus optics for sports applications.

Most professional setups utilize eight individual LED floodlights mounted on four six-meter poles to eliminate shadows during fast-paced nocturnal matches for better visibility. These IP67-rated lights are designed to withstand heavy rain plus dust while providing consistent color temperature of five thousand Kelvin for play. Low-quality lighting creates glare that distracts players plus reduces safety of your facility during evening peak hours when demand is highest for courts. Expect to allocate roughly ten percent of your total hardware budget to electrical plus lighting components for a professional standard court finish.

What is the ideal lux level for play?

Tournament-grade courts require at least five hundred lux of uniform light across entire playing surface to meet professional broadcast standards for television events. Ready for the good part? Using high-efficiency two-hundred-watt LED chips reduces your monthly electricity bill by sixty percent compared to old metal halide bulbs for savings. Uniform light distribution ensures players can track ball accurately even when moving rapidly against back glass walls during defensive lobs or smashes. Smart lighting controllers can also be added to allow remote scheduling or motion-based activation for unstaffed club hours during early morning sessions.

- 500 lux uniform distribution

- 200W high-efficiency LED chips

- 5000K daylight color temperature

- Remote smart control options

How do light poles affect the structure?

Integrated light poles that are part of main steel frame provide cleaner aesthetic plus more stability during high winds for outdoor court installations. What’s the real story? These poles must be hot-dip galvanized plus powder-coated to match rest of court while hiding all internal electrical wiring from rain exposure. Proper wiring concealment prevents vandalism plus protects cables from UV degradation over years of exposure to sun in tropical or desert climates. Reinforced mounting brackets ensure heavy light fixtures do not vibrate or shift during intense play or stormy weather conditions in your area.

- Integrated frame pole design

- Internal concealed wiring systems

- UV protected cable housing

- Reinforced fixture mounting brackets

Key Takeaway: Quality LED lighting costs about $2,000 per court but reduces energy bills and increases playable hours.

| Light Feature | Specification | Benefit | Cost Rating |

|---|---|---|---|

| Power | 200W per lamp | Brightness | Medium |

| Protection | IP67 Rated | Waterproof | Low |

| Lifespan | 50,000 Hours | Low Maintenance | High Value |

Will monofilament turf increase how much does a padel court cost?

The type of synthetic grass you choose will change how much does a padel court cost due to variations in fiber density plus pile height.

Monofilament turf is widely considered gold standard because it offers superior durability plus more consistent ball bounce than cheaper fibrillated options for players. While it costs slightly more per square meter, reduction in sand displacement means your staff will spend less time grooming surface every week. Most professional courts use twelve-millimeter pile height which is specifically designed to handle lateral movements of padel players during fast intense rallies. This high-density turf also provides better shock absorption to protect knees plus joints of your club members over long periods of athletic play.

Why choose blue turf over green?

Blue turf has become iconic color for padel because it provides best visual contrast with yellow ball for players plus television cameras during. You might be wondering. While color itself does not change manufacturing price, choosing non-standard color might slightly extend your delivery lead time for custom production orders. UV-stabilized fibers ensure vibrant color does not fade under intense sunlight in tropical or desert environments over several years of outdoor exposure. High-quality backing materials prevent turf from stretching or wrinkling when temperature fluctuates throughout different seasons in your specific geographical region or city.

- High-contrast blue fiber color

- UV-stabilized material technology

- Superior ball bounce consistency

- Reduced sand displacement needs

How much sand infill is required?

Proper infill with rounded silica sand is necessary to keep fibers upright plus provide correct amount of slide for players during active movement. This is where it gets interesting. You typically need about three thousand kilograms of specialized sand per court to achieve perfect balance of grip plus player safety for members. Using wrong type of sand can lead to premature turf wear or dangerous slippery spots that cause player injuries during fast matches on. Distributing sand evenly is critical final step in installation process that ensures court plays perfectly from day one for all your paying customers.

- 3,000kg silica sand infill

- Rounded grain safety profile

- Even distribution maintenance tool

- Fiber support stability function

Key Takeaway: Monofilament blue turf is the professional choice, costing slightly more but offering better durability and player safety.

| Turf Type | Fiber | Maintenance | Player Comfort |

|---|---|---|---|

| Monofilament | Single Strand | Low | High |

| Fibrillated | Split Fiber | Medium | Medium |

| Curly (Texturized) | Textured | Very Low | Premium |

How much does a padel court cost for international shipping fees?

Logistics plus freight significantly influence how much does a padel court cost when you are importing materials from overseas factory locations for projects.

One complete padel court kit typically occupies about fourteen cubic meters plus fits inside forty-foot high-cube shipping container along with another court unit. Shipping costs fluctuate based on global oil prices plus port congestion, so getting landed quote is necessary for your final development budget planning. You must also factor in local import duties, customs clearance fees, plus trucking from port to construction site for total landed cost. Buying multiple courts at once allows you to maximize container space plus reduce per-unit shipping expense dramatically for your large scale sports facility.

How are courts packed for transport?

Professional manufacturers use shock-proof packaging plus steel pallets to ensure heavy glass panels do not break during rough sea voyages or handling. Ready for the good part? Every component is labeled plus bundled according to assembly sequence to make unloading at your facility as efficient as possible for workers. Specialized protective foam plus plastic wrapping prevent scratches on powder-coated steel surfaces while kits sit in transit for several weeks across oceans. This attention to detail in packing phase saves you hundreds of dollars in potential replacement costs for damaged items upon arrival at site.

- Steel pallet reinforcement systems

- Shock-proof glass crate design

- Sequence-labeled component bundles

- UV-protective plastic wrapping layers

What are common import taxes?

Depending on your country, you might face import tariffs ranging from five to twenty percent of total invoice value of your courts. Check this out. Some regions offer tax incentives for sports equipment or recreational facilities which can help lower your total investment cost significantly for new clubs. Always verify Harmonized System codes with your customs broker to ensure you are paying correct tax rate for steel structures and glass. Preparing documentation in advance will prevent expensive storage fees at port while waiting for customs clearance approval for your imported padel court kits.

- 5-20% standard import duty

- Local sports facility incentives

- Customs brokerage processing fees

- Port storage avoidance strategy

Key Takeaway: Shipping and taxes can add 15-30% to your total budget; bulk ordering reduces the per-court logistical cost.

| Shipping Factor | Impact | Optimization Tip |

|---|---|---|

| Container Volume | 14 CBM per court | Order 2 courts per 20GP |

| Packing | Steel Pallets | Prevents glass breakage |

| Duties | 5% – 20% | Check local sports incentives |

What assembly steps influence how much does a padel court cost now?

Labor for final construction phase is vital part of how much does a padel court cost in today’s competitive global sports market.

Standard court requires team of four skilled workers approximately three to five days to complete mechanical assembly once foundation is ready for. You will need specialized equipment like small crane or glass suction lifters to handle heavy tempered panels safely during installation on site. Hiring experienced installation crew ensures frame is perfectly square plus glass is properly aligned to prevent future stress fractures from occurring later. Proper tensioning of net plus even distribution of turf sand are finishing touches that define premium court experience for your club members.

Can you assemble a court yourself?

While some facility owners attempt DIY installation, complexity of aligning three-meter glass panels often makes professional labor safer investment for your business. Here is the deal. Improperly installed bolts or misaligned frames can lead to structural failure or glass breakage which costs much more to repair over time. Most manufacturers provide detailed installation manual plus video guides to help your local contractor follow correct engineering sequence during the build. Having at least one supervisor with previous padel experience can save you days of labor by avoiding common assembly mistakes for your project.

- Professional team of 4

- 3-5 days assembly duration

- Safety compliance verification steps

- Detailed technical video guides

What tools are required for building?

You will need variety of professional tools including laser levels, impact wrenches, plus heavy-duty drilling equipment for concrete anchors during the process. What’s the catch? Specialized turf cutting tools plus adhesive spreaders are required to create invisible seams between synthetic grass rolls for a clean finish. Ensuring you have correct high-tensile bolts plus stainless steel washers prevents structure from loosening under vibration of constant play during matches on. Renting scissor lift or scaffolding allows your team to install lighting fixtures plus top rails safely at six-meter height for your new facility.

- Laser leveling equipment sets

- High-torque impact wrenches

- Professional glass suction lifters

- Turf seam adhesive spreaders

Key Takeaway: Professional installation takes 3-5 days and costs between $2,000 and $5,000 depending on your local labor rates.

| Assembly Phase | Duration | Equipment Needed |

|---|---|---|

| Frame Bolting | 1 Day | Impact Wrench, Level |

| Glass Mounting | 1-2 Days | Suction Lifters, Scissor Lift |

| Turf & Sand | 1 Day | Turf Cutter, Sand Spreader |

How much does a padel court cost for ongoing maintenance services?

You must account for operational expenses when calculating how much does a padel court cost over its entire functional lifespan for your business.

Synthetic turf requires weekly brushing to redistribute sand infill plus prevent fibers from matting down under heavy foot traffic at your club. You should also check tension of perimeter glass bolts every six months to ensure structure remains rigid plus safe for all players. Cleaning glass panels with standard water plus mild detergent keeps court looking premium plus professional for your members throughout all the seasons. Budgeting roughly five hundred to one thousand dollars per year for basic maintenance will keep your court in top condition for many decades.

How often should the turf be replaced?

High-quality monofilament turf usually lasts between five plus eight years in high-traffic commercial club before needing full replacement for optimal play quality. But here’s the kicker. Proper weekly maintenance can extend this lifespan significantly by preventing fibers from breaking off due to sand friction over many hours of play. Replacing just turf surface is relatively simple process that costs about four thousand dollars plus takes only two days to complete for. Regular inspection for loose seams allows you to repair small issues before they become major tripping hazards for your active players at site.

- 5-8 year turf lifespan

- Weekly fiber brushing routine

- Strategic sand top-up schedule

- Seam repair plus inspection

What happens if a glass panel breaks?

While tempered glass is extremely strong, accidental breakage can occur from extreme impacts or severe ground shifts in rare cases during heavy use. You might be wondering. Keeping spare panel on-site is smart move for large clubs to minimize court downtime plus lost revenue while waiting for replacement part. Replacement panels are relatively inexpensive at factory level but shipping single piece of glass is costly due to protective crate requirement for sea. Most insurance policies for sports facilities cover glass breakage, so ensure your coverage is updated once construction is finished for your new club.

- On-site spare panel storage

- Factory direct replacement ordering

- Insurance coverage for glass

- Rapid replacement installation steps

Key Takeaway: Annual maintenance is low ($500-$1,000), mainly involving turf brushing and glass cleaning to protect your investment.

| Task | Frequency | Estimated Cost |

|---|---|---|

| Turf Brushing | Weekly | Staff Time |

| Glass Cleaning | Monthly | $50 |

| Bolt Inspection | Bi-Annually | $100 |

| Sand Top-up | Annually | $200 |

How to minimize how much does a padel court cost via factory direct?

Sourcing directly from manufacturer is most effective way to lower how much does a padel court cost without compromising on material quality.

By eliminating local distributors, you can save up to thirty percent on hardware costs while getting access to full OEM customization options for. You can choose specific RAL colors for your frame plus even have your club logo permanently etched into glass panels or the net. Factory-direct shipping also ensures you receive latest structural designs plus most recent turf technology available in international market for your new sports facility. This strategy allows you to build world-class facility while staying within modest development budget for your growing padel tennis business venture projects.

Why is OEM customization beneficial?

Direct communication with factory allows you to adjust court specifications to match local climate or branding requirements perfectly for your unique project vision. Ready for the good part? You can request extra thick galvanization for coastal projects or reinforced wind-resistant supports for outdoor courts in hurricane-prone regions or stormy areas. Choosing custom color like matte black or vibrant orange helps your facility stand out in marketing materials plus social media posts for members. These small details create unique brand identity that attracts more players plus justifies higher hourly rental rates for your professional padel courts today.

- Custom RAL frame colors

- Etched logo glass options

- Climate-specific steel upgrades

- Unique turf color palettes

What should you look for in a supplier?

Reliable supplier should provide CE certification, ISO quality management documentation, plus proven track record of international deliveries to multiple countries around world. What’s the real story? Request virtual factory tour to see robotic welding systems plus material testing lab before placing your final order for your new courts. Professional manufacturer will offer 24-hour technical support plus comprehensive warranty that covers steel structure for several years of heavy commercial usage on. Establishing direct relationship with production team ensures you get best pricing plus priority during peak manufacturing seasons for your upcoming club expansion.

- CE plus ISO certifications

- Proven global delivery history

- 24-hour technical support access

- Comprehensive structural warranty plans

Key Takeaway: Buying factory-direct saves 30% and provides total control over colors, logos, and structural specifications.

| Buying Path | Markup | Customization | Support |

|---|---|---|---|

| Local Distributor | 20% – 40% | Limited | Local |

| Factory Direct | 0% | Full OEM | Technical Team |

| Used Court | Varies | None | None |

Summary

Building a padel court is strategic investment that requires balancing initial hardware costs with long-term durability plus safety for your sports club. By focusing on high-quality Q235 galvanized steel plus twelve-millimeter tempered glass, you ensure facility that lasts over fifteen years of play. Site preparation plus professional installation are vital steps that protect structural integrity of your court kit against environmental factors or heavy usage. Sourcing directly from manufacturer allows you to maximize budget plus customize every detail of your sports club branding for a unique look. If you are ready to start your project, contact us today for a professional quotation tailored to your specific facility needs.

FAQ

Can I install a padel court on an existing tennis court surface?

Yes, but you must verify that the concrete or asphalt is at least fifteen centimeters thick and perfectly level to support the weight of the steel and glass.

What’s the best way to protect my court from rust in a coastal area?

The best solution is to use hot-dip galvanized steel with an extra layer of marine-grade powder coating to prevent salt-air corrosion.

How do I know if I need a panoramic or standard court for my club?

If you plan to host tournaments with spectators or want a premium aesthetic for a luxury resort, the panoramic model is the superior choice for visibility.

Can I customize the color of the turf to match my corporate branding?

Yes, while blue is standard, you can order turf in green, red, or even black to match your facility’s specific aesthetic requirements.

What’s the best way to reduce shipping costs for multiple courts?

The most efficient method is to order two courts at a time, as they fit perfectly into a single forty-foot high-cube shipping container.