Investing in a sports facility often starts with a vision of high occupancy and happy players, but you might quickly find yourself staring at cracked glass, rusted fences, or “dead” turf spots that ruin the game. These structural failures do more than just look bad; they actively drive away your premium clientele and create a massive liability that could shutter your business overnight. Here is the deal. By understanding the technical requirements of professional fields padel, you can transition from a risky construction project to a high-yield, durable asset that dominates the local market. Building these environments requires an expert grasp of engineering tolerances and material science, ensuring that every match played is safe, fast, and commercially viable for your organization.

What are the core components of professional fields padel?

When you begin evaluating the blueprints for your facility, you must realize that fields padel are complex engineering systems rather than just fenced-in enclosures. The interplay between the metallic frame and the playing surface determines how the ball behaves and how safe your players remain during high-intensity matches. A professional structure relies on high-grade steel that can withstand constant vibration and player impact, preventing the “rattling” effect common in cheaper alternatives.

Metallic Structure and Mesh Specifications

A professional structure relies on high-grade steel that can withstand constant vibration and player impact. You should look for tube thickness usually at 80x80mm or 100x50mm for the primary pillars. The electro-welded mesh must be flush with the frame to prevent irregular ball bounces that frustrate advanced athletes. Think about this. The quality of the welding at the joints determines if the cage will start vibrating after just six months of use, leading to hardware fatigue.

Standard Dimensions and Play Area Markings

The playing area must strictly adhere to a 20m x 10m footprint, measured from the internal face of the enclosures. You need to ensure the service lines are positioned 6.95m from the net, with a central line dividing the service boxes precisely. Any deviation in these measurements can disqualify your facility from hosting official tournaments, limiting your revenue potential.

| Component | Standard Requirement | Performance Impact |

|---|---|---|

| Primary Pillars | Q355 Steel | Structural Integrity |

| Mesh Type | 50x50x4mm | Consistent Bounce |

| Net Height | 88cm (Center) | Regulation Play |

Key Takeaway: The structural skeleton of the court provides the essential foundation for playability; skipping on steel quality leads to premature vibration and maintenance headaches.

How do synthetic turf systems impact fields padel?

The choice of turf is arguably the most critical decision for player satisfaction in modern fields padel. You are not just looking for green carpet; you are looking for a biomechanical surface that offers the right balance of grip and slide while managing moisture effectively. It gets better. High-quality textured turf minimizes sand migration and maximizes “up-time” by ensuring the court is playable immediately after rain.

Monofilament vs Fibrillated Fiber Technology

Textured monofilament fibers are currently the preferred choice for professional venues because they hold the sand infill more effectively. This reduces the “splash” of sand during play and ensures the fibers remain upright even under heavy foot traffic. You should prioritize UV-stabilized polyethylene fibers to prevent the surface from becoming brittle and abrasive over time.

Infill Ratios and Drainage Performance

The silica sand must be 99% pure, washed, and dried to prevent clumping that ruins drainage. Typically, you need a grain size of 0.2mm to 0.5mm for optimal drainage and ball speed. The backing must allow water to pass through at a rate exceeding 30 liters per minute per square meter to ensure the facility stays operational during the rainy season.

| Turf Feature | Specification | Performance Result |

|---|---|---|

| Fiber Type | Textured Monofilament | Sand Retention |

| Infill | 15-18kg Silica per m2 | Surface Stability |

| Drainage | 30+ Liters/min/m2 | All-weather Uptime |

Key Takeaway: High-quality textured turf minimizes sand migration and maximizes player safety by providing a predictable, high-grip surface.

Why is structural safety vital for fields padel?

Safety is not an area where you can afford to cut corners, especially when fields padel are subject to significant wind loads and physical impacts from players chasing “out of court” shots. A structural failure is not just an expensive repair; it is a catastrophic reputation killer for your brand. Mark my words. Without proper anchoring, the entire glass wall can act like a sail during a storm, potentially ripping the foundation right out of the ground.

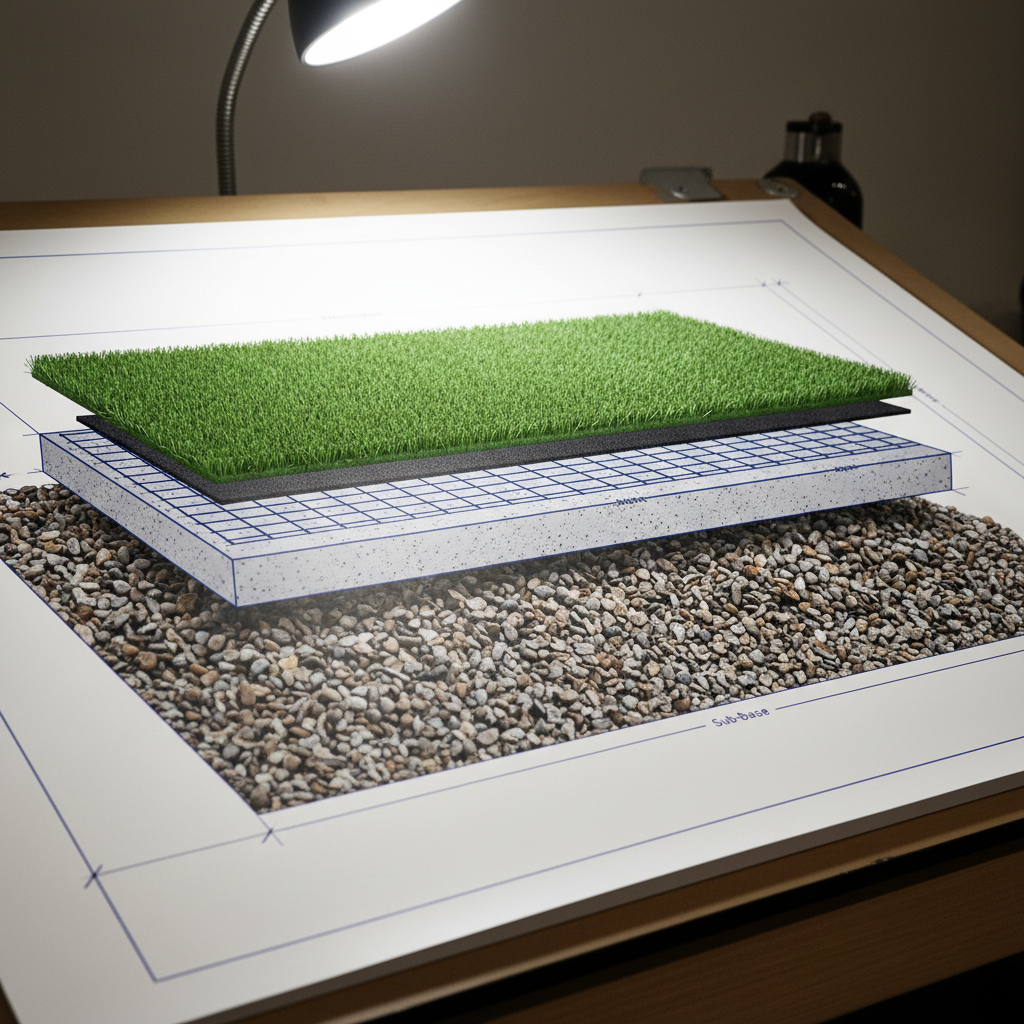

Foundation Depth and Leveling Precision

A reinforced concrete ring beam is necessary to anchor the pillars against dynamic loads. You must ensure the surface has a slight slope (usually 0.5% to 1%) toward the edges to facilitate water runoff, unless you are using porous concrete. Laser leveling is the only way to achieve the sub-3mm tolerance required to prevent glass panels from being installed under tension.

Wind Load Resistance and Stability

You must include gusset plates, which are extra triangular steel supports at the base of the pillars, to manage lateral forces. High-tensile stainless steel anchor bolts (M12 or M16) should be used for all floor connections to prevent rust-induced failure. The structure should be rated for wind speeds of at least 100 km/h to protect your long-term investment.

| Safety Element | Specification | Benefit |

|---|---|---|

| Concrete Grade | C25/30 Minimum | Secure Anchoring |

| Bolt Type | M12/M16 Stainless | Rust Prevention |

| Welding | Robotic CNC | Uniform Strength |

Key Takeaway: Engineering for peak wind loads and player impacts ensures your facility remains a safe environment and a protected investment for decades.

What glass specifications are used in fields padel?

The transparency of your venue is what makes it a spectator sport, but the glass in fields padel must be incredibly resilient. You need a material that can withstand the force of a 100kg player hitting the wall at full speed without shattering into dangerous shards. Here is the kicker. Using 12mm glass instead of 10mm provides a significantly more professional “rebound,” keeping the ball in play longer and satisfying advanced members.

Tempered Safety Glass Standards

You should always opt for 10mm or 12mm tempered glass that meets EN 12150-1 standards. This heat-treatment process makes the glass five times stronger than regular glass and ensures that if it does break, it crumbles into small, dull-edged pebbles. CNC-machined holes are required to ensure the hardware fits perfectly without creating stress points that lead to spontaneous shatters.

Hidden Anchor and Neoprene Gasket Systems

Plastic bushings are essential inserts that prevent the metal bolts from touching the glass directly, which is the leading cause of breakage. EPDM gaskets act as shock absorbers between the steel frame and the glass panels, allowing the structure to “breathe” during temperature changes. You should also look for countersunk hardware to ensure a flush finish that prevents erratic ball deflections.

| Glass Detail | Requirement | Safety Impact |

|---|---|---|

| Process | Heat-Tempered | High Strength |

| Edge Finish | CNC Polished | Crack Prevention |

| Bushings | Plastic/Rubber | Metal Separation |

Key Takeaway: High-spec tempered glass is the only option for professional courts; 12mm thickness provides the superior “rebound” feel that elite players demand.

How should you plan the lighting for fields padel?

If you want to maximize your evening revenue, the lighting for your fields padel must be flawless. Players cannot react to a ball traveling at 120 km/h if they are struggling with shadows or glare from poorly positioned floodlights. Make no mistake. Cheap lighting leads to “flicker” on phone cameras, which prevents your players from sharing their highlights on social media—your best free marketing tool.

LED Floodlight Intensity and Uniformity

A professional setup usually requires eight 200W LED floodlights mounted on four poles. You are aiming for an average illuminance of 500 to 750 lux, with a uniformity ratio (min/average) of at least 0.7 to ensure no dark spots. This level of brightness is necessary for high-speed tracking and reduces eye strain during long evening sessions.

Anti-Glare Design for High-Lobs

Asymmetric lenses are vital for directing light onto the court while keeping the source out of the players’ direct line of sight. This is especially important for lobs and overhead smashes, where players are looking directly upward. You should choose a color temperature between 5000K and 5700K to provide a crisp, daylight-like environment that looks great on camera.

| Feature | LED Standard | Metal Halide (Avoid) |

|---|---|---|

| Energy Usage | Low (800W-1600W total) | High (3200W+ total) |

| Lifespan | 50,000+ Hours | 10,000 Hours |

| Warm-up Time | 0 Seconds | 10-15 Minutes |

Key Takeaway: Investing in premium LED lighting extends your playable hours and ensures a high-quality visual experience for both players and spectators.

What are the installation steps for fields padel?

The best materials in the world cannot save a poorly installed court, which is why the assembly of fields padel requires specialized crews. Small errors in the initial foundation or the verticality of the pillars will compound as you try to fit the glass panels and the turf. Believe it or not. A specialized crew can install a full court in just 3-4 days if the foundation is properly prepared, but a DIY approach often leads to weeks of delays.

Precision Leveling and Alignment

The first step is verifying the sub-base with laser tools. Any deviation larger than 3mm over a 3-meter span must be corrected before the steel structure is bolted down. You must ensure the pillars are perfectly vertical using plumb lines, as even a 1-degree tilt will prevent the glass panels from aligning with the frame.

Glass Placement and Turf Fitting

Professional crews use high-power suction cups to maneuver 160kg panels safely into position. The turf rolls must be joined using specialized polyurethane adhesive and geo-textile tape to ensure the seams remain invisible and durable. Finally, a mechanical spreader is used to ensure a perfectly even layer of silica sand, which is essential for consistent ball bounce.

| Phase | Core Tool | Success Metric |

|---|---|---|

| Foundation | Laser Level | 100% Flatness |

| Structure | Plumb Line | Perfect Verticality |

| Finishing | Sand Spreader | Uniform Infill |

Key Takeaway: Professional installation is a non-negotiable step; using experienced crews prevents structural misalignment and long-term turf failures.

How do weather conditions affect fields padel?

If you are building an outdoor facility, you must account for the environmental stressors that will act on your fields padel year-round. From intense UV radiation that fades turf to the salt spray in coastal areas that eats through steel, your choice of coatings is your first line of defense. Now consider this. A court with poor rust protection will show signs of “bleeding” orange stains onto the white turf within just two seasons.

Corrosion Protection and Powder Coating

For outdoor courts, a hot-dip galvanized finish is essential. This process creates a metallurgical bond that protects the steel inside and out. You should follow this with an electrostatic powder coating, which provides a vibrant color and a secondary layer of protection against chipping. Stainless steel fasteners should be used throughout to prevent local corrosion at the joints.

UV Resistance and All-Weather Protection

The synthetic turf fibers must be treated with UV stabilizers to prevent the plastic from becoming brittle and shedding. You should also ensure the backing is perforated to allow for immediate drainage after heavy rain. Adding a permanent canopy or roofing solution can protect your assets from the sun, potentially doubling the lifespan of your nets and turf.

| Climate Issue | Technical Solution | Result |

|---|---|---|

| Coastal Salt | Double Galvanization | 15+ Year Rust Warranty |

| High Heat | UV-Stabilized PE | Retains Color & Texture |

| Heavy Rain | Perforated Backing | 5-Minute Drainage |

Key Takeaway: Designing for your specific climate—whether through superior coatings or roofing—drastically reduces your long-term depreciation and maintenance costs.

What maintenance is required for fields padel?

You cannot simply build a facility and walk away; the longevity of fields padel depends on a proactive maintenance schedule. Regular care keeps the court looking premium and ensures the playing characteristics remain consistent for the life of the turf. This is important. Neglecting to brush the sand leads to fiber “folding,” where the grass lies flat and wears out twice as fast as properly maintained turf.

Brushing and Sand Redistribution

Every 50 hours of play, the turf should be brushed to redistribute the silica sand. This prevents the sand from compacting at the bottom, which makes the surface feel “hard” and slippery for the players. You should also check for “low spots” in the sand near the net and baseline, as these areas experience the most foot traffic and impact.

Structural and Glass Inspections

Vibrations from play can loosen the hardware over time, so you should tighten all structural bolts every three months. Glass walls should be cleaned weekly using non-abrasive tools to maintain 100% transparency. In shaded areas, you might need a light fungicidal wash once a year to prevent algae growth on the turf or the base of the glass panels.

| Task | Interval | Importance |

|---|---|---|

| Brushing | Every 50 Hours | Fiber Protection |

| Bolt Check | Every 3 Months | Structural Integrity |

| Glass Wash | Weekly | Spectator Appeal |

Key Takeaway: A simple weekly maintenance routine can extend the life of your turf by up to 30% and keeps the playing experience at a “pro” level.

How do you choose between different types of fields padel?

The layout of your club will determine which style of fields padel is right for your business model. While standard courts are functional and cost-effective for training, premium “panoramic” designs offer a much better experience for fans and broadcasters. The truth is. Choosing a panoramic layout can allow you to charge higher booking fees due to the premium atmosphere it creates for your community.

Standard vs Panoramic Layouts

Standard courts use vertical pillars every 2 meters, which is highly stable but creates visual obstructions for spectators. Panoramic models remove the rear pillars, using 12mm glass and reinforced horizontal beams to maintain structural integrity. These “fishbowl” designs are the industry gold standard for center courts and are essential if you plan to host televised matches or high-profile tournaments.

Venue Specific Selection Criteria

If you are building a multi-sport center, you might consider portable versions that can be moved for special events. For areas with high rainfall, a roofed configuration is the only way to guarantee 365-day operation. You should also evaluate “Super Panoramic” designs, which remove even the corner pillars, offering 100% visibility for cameras and live audiences.

| Court Type | Primary Advantage | Best Location |

|---|---|---|

| Standard | Cost-Effective Build | Training Centers |

| Panoramic | Unobstructed Views | Center Courts |

| Roofed | 365-Day Operation | High-Rain Areas |

Key Takeaway: Match your court style to your revenue goals; panoramic courts command higher booking fees and are the preferred choice for high-profile matches.

What is the ROI potential for investing in fields padel?

When you analyze the economics of fields padel, the numbers are often more attractive than traditional tennis or fitness centers. Because four players occupy a space significantly smaller than a tennis court, the revenue per square meter is vastly higher for the operator. Think about this. By choosing a professional build now, you avoid the “cheap court” trap where repair costs eat 20% of your monthly revenue after the first year.

Operational Efficiency and Booking Density

A well-managed court can run for 12 to 14 hours a day with minimal staffing. With four players paying per hour, the payback period for a high-quality court can be as short as 18 to 24 months in a busy urban area. Automated booking systems and smart LED lighting further reduce overhead, allowing you to run a highly profitable, low-labor business.

Long-Term Asset Value and Resale

High-spec galvanized steel and premium turf keep the asset’s value high for over 15 years. Unlike gyms with expensive, high-maintenance machinery, padel courts have very low depreciation if the maintenance schedule is followed. This makes them a stable commercial asset that generates steady cash flow while maintaining strong resale potential if you ever decide to exit the business.

| Investment Metric | Professional Build | Budget Build |

|---|---|---|

| Initial Cost | Moderate to High | Low |

| Annual Maintenance | Low | High (Repairs) |

| Asset Lifespan | 15-20 Years | 5-7 Years |

Key Takeaway: Investing in premium construction quality maximizes your ROI by minimizing downtime and maintaining high booking rates through a superior player experience.

*

Build Your Legacy with Professional Courts

Investing in a sports facility is about more than just steel and glass; it is about creating a safe, vibrant space where your community can thrive. We help you solve the common problems of structural instability and surface degradation by providing the most durable materials available. Our vision is to elevate the standard of sports construction through precision engineering and a deep understanding