What does a padel court manufacturer actually do?

A padel court manufacturer is responsible for the precision engineering and fabrication of the metal structure, the tempering of safety glass, and the procurement of professional-grade turf. By selecting a padel court manufacturer, you ensure that the complex interplay between structural rigidity and player safety is managed by experts.

How does production differ from installation?

Production involves the industrial fabrication of components in a controlled factory environment to ensure consistency. But that’s not all.

- Laser cutting of steel profiles.

- Automated galvanization processes.

- Thermal tempering of glass panels.

Why is technical design the first priority?

Technical design ensures the court can withstand localized wind loads and constant player impact. Here is why:

- CAD drawings define exact anchor points.

- Static calculations prevent structural fatigue.

- Drainage layouts are integrated into the blueprints.

Key Takeaway

Technical precision during the manufacturing phase eliminates the risk of onsite misalignments and structural failure.

| Stage | Focus | Outcome |

|---|---|---|

| Production | Component Fabrication | FIP-compliant hardware |

| Design | Structural Engineering | Long-term facility safety |

Comprehensive manufacturing covers every detail from the bolt tension to the luminosity of the LED lighting systems.

Why is choosing a specialist padel court manufacturer critical?

A specialized padel court manufacturer understands the unique vibration and impact stresses that a padel court must endure compared to standard fencing. Choosing a dedicated padel court manufacturer guarantees that the materials used are specifically rated for high-frequency ball rebounds and player collisions.

What risks arise from low-quality materials?

Low-quality materials can lead to rapid oxidation of the steel and uneven glass surfaces. Believe it or not.

- Premature rusting in humid climates.

- Glass breakage from thermal stress.

- Turf balding within the first year.

How does certification impact player safety?

Certification from bodies like the FIP ensures the court meets international safety and performance benchmarks. Think about this:

- Verified glass fragmentation patterns.

- Standardized bounce height across the turf.

- Electro-welded mesh that prevents skin abrasions.

Key Takeaway

Specialized certification is the only way to protect your business from liability and ensure a professional player experience.

| Material | Risk Level | Benefit of Specialist |

|---|---|---|

| Untreated Steel | High (Rust) | Hot-dip galvanization |

| Standard Glass | Extreme (Injury) | 12mm Tempered Safety Glass |

Investing in specialized manufacturing prevents the hidden costs associated with early structural degradation and player injury claims.

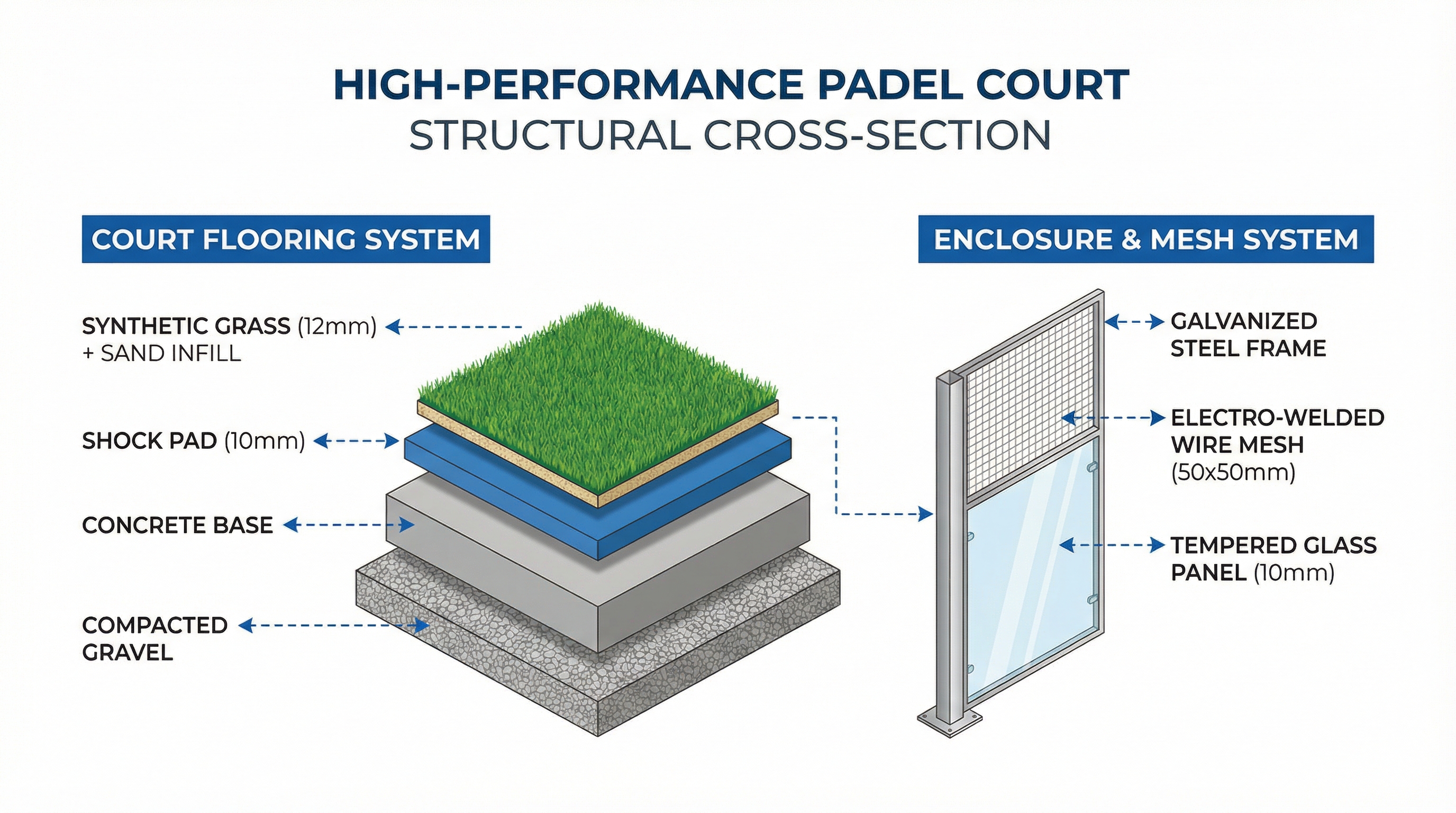

What parts does a padel court manufacturer produce?

A padel court manufacturer produces the galvanized steel pillars, the electro-welded wire mesh, the tempered glass walls, and the specialized lighting masts. Every padel court manufacturer must ensure these parts work in harmony to create a stable, high-performance environment.

How does the frame affect structural integrity?

The frame acts as the skeleton that absorbs the force of players running into the walls. It is quite simple.

- 100x50mm or 80x80mm steel profiles.

- Laser-welded gussets for corner reinforcement.

- Anti-vibration gaskets between steel and glass.

What materials ensure long-term durability?

Durability depends on the quality of the anti-corrosion treatments and the density of the synthetic turf fibers. Here is the deal:

- Powder coating for UV resistance.

- Monofilament or textured turf fibers.

- Stainless steel hardware for all connections.

Key Takeaway

High-quality components reduce the total cost of ownership by extending the maintenance interval of the facility.

| Component | Material Standard | Purpose |

|---|---|---|

| Mesh Panels | 50x50x4mm Steel | Consistent ball rebound |

| Turf | Polyethylene (PE) | Player joint protection |

The synergy between the steel frame and glass panels is what determines the “feel” and speed of the game.

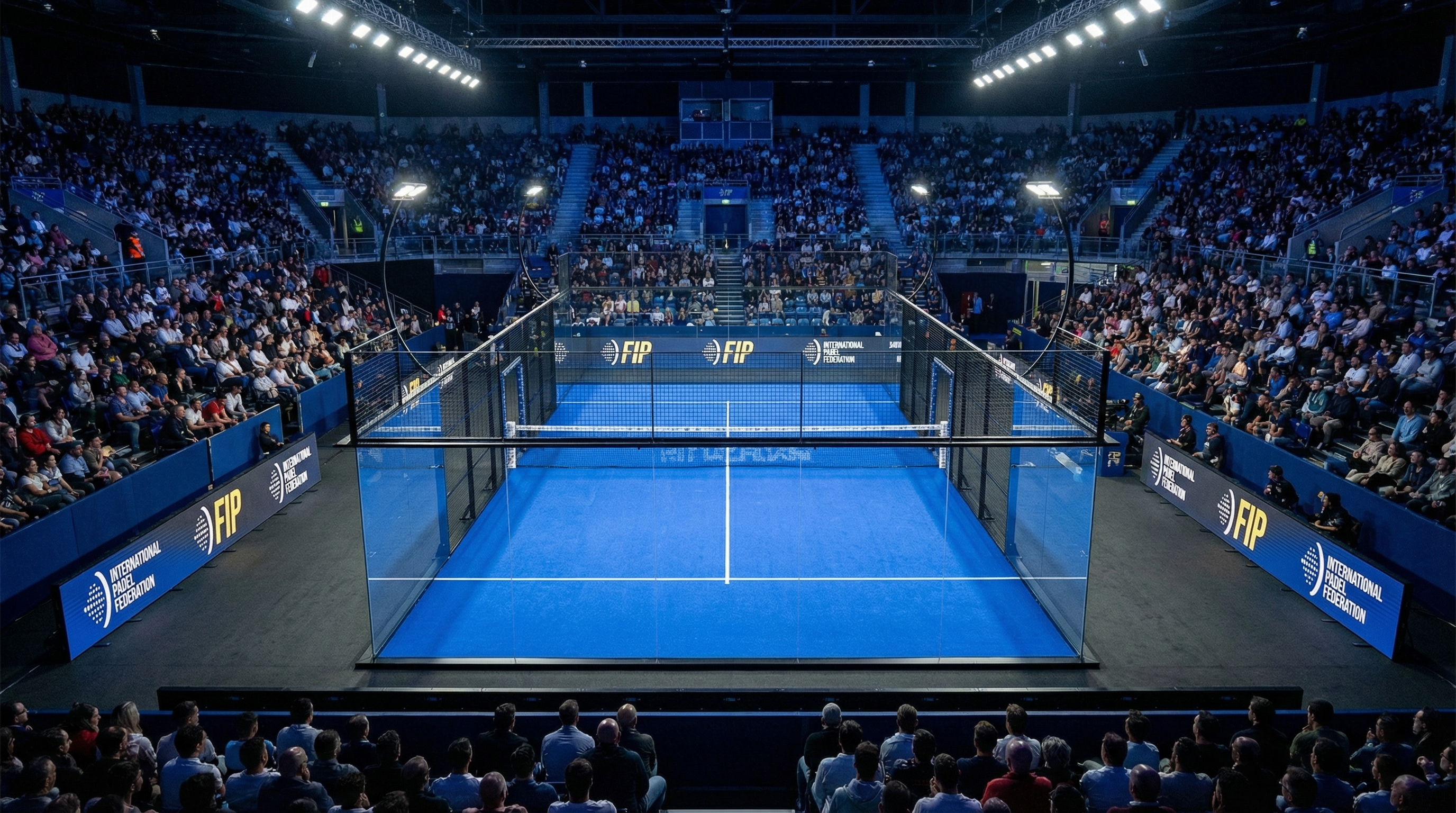

Can a padel court manufacturer build panoramic views?

A padel court manufacturer can certainly build panoramic models which replace traditional corner pillars with thick, high-tension glass for better visibility. When you consult a padel court manufacturer, they will explain that these models require more robust engineering to maintain stability without the extra steel support.

What are the benefits of a standard design?

Standard designs offer a cost-effective and highly durable solution for high-traffic clubs. Keep this in mind.

- Easier installation for local crews.

- Lower initial capital investment.

- Modular parts that are easy to replace.

Is a panoramic view worth the extra investment?

Panoramic views are essential for center courts and clubs that want to host filmed tournaments or spectators. You should know:

- Unobstructed views for video recording.

- Premium aesthetic that attracts elite players.

- Increased “prestige” value for the club brand.

Key Takeaway

Choose panoramic designs for your showcase courts to maximize spectator engagement and social media marketing potential.

| Court Type | Best Use Case | Visibility Rating |

|---|---|---|

| Standard | Daily club play | Good |

| Panoramic | Tournament center courts | Excellent |

The choice between standard and panoramic should be driven by your club’s business model and target demographic.

When does a padel court manufacturer use super panoramic?

A padel court manufacturer uses super panoramic designs when a project requires a “total glass” look with virtually no visible vertical supports. A padel court manufacturer typically reserves this model for professional stadiums where the highest level of transparency is required for television broadcasts.

Is this the right choice for pro tournaments?

Super panoramic courts are the gold standard for World Padel Tour-style events. It’s the truth.

- Maximum brand exposure on the glass.

- Optimal lighting conditions for HD cameras.

- Wider perimeter for out-of-court play.

How does the absence of pillars change the game?

The absence of pillars creates a more immersive experience for the players and the audience alike. Here is why:

- Enhanced peripheral vision during play.

- More uniform glass bounce across the back wall.

- Sleek, modern architectural appearance.

Key Takeaway

Super panoramic models are an investment in the “spectacle” of padel, designed specifically for high-level competition and broadcasting.

| Feature | Super Panoramic | Standard Panoramic |

|---|---|---|

| Support Structure | Hidden/Reinforced Base | Minimal Corner Pillars |

| Glass Thickness | 12mm Heat-Strengthened | 10mm or 12mm Tempered |

Super panoramic engineering represents the pinnacle of padel technology, balancing extreme transparency with structural rigidity.

How does a padel court manufacturer handle climate?

A padel court manufacturer handles climate challenges by adjusting the grade of steel galvanization and the thickness of the glass to suit local weather patterns. A padel court manufacturer must conduct a site-specific analysis to ensure the court can withstand humidity, snow loads, or high winds.

Are roofed courts better for rainy regions?

Roofed courts are essential in regions where rain or extreme sun can limit the number of playable hours. Consider this:

- Guaranteed year-round revenue.

- Protection for the turf and glass.

- Lower long-term maintenance costs.

What materials resist high wind loads?

For coastal or open-area installations, manufacturers use reinforced pillars and thicker glass panels. Here is how:

- Increased steel wall thickness.

- Large-format base plates with extra anchors.

- Wind-rated glass clips and connectors.

Key Takeaway

Customizing your court’s specifications for your local climate prevents catastrophic weather damage and maximizes your return on investment.

| Climate Type | Recommended Feature | Outcome |

|---|---|---|

| Coastal | Triple-layer galvanization | No salt-air corrosion |

| High Wind | 12mm Tempered Glass | Structural safety during storms |

Climate adaptation is a non-negotiable step in the manufacturing process for outdoor facilities.

What space does a padel court manufacturer require?

A padel court manufacturer requires a minimum clear area of 20 meters by 10 meters for the playing surface, plus a buffer zone for the structure and player safety. Working with a padel court manufacturer ensures you account for the extra space needed for pillars, lighting masts, and out-of-court play.

Is your foundation ready for glass and steel?

The foundation must be a perfectly level, reinforced concrete slab capable of supporting several tons of concentrated weight. Take note.

- 15cm to 20cm thickness is standard.

- 1% slope for efficient water drainage.

- Reinforcement mesh to prevent cracking.

How much buffer zone do you need for safety?

A buffer zone allows players to safely retrieve balls that go out of bounds without hitting walls or other courts. It is vital.

- 2 meters of side clearance is ideal.

- Clear height of at least 7 meters.

- Dedicated paths for spectator movement.

Key Takeaway

Proper site planning ensures that your manufactured court is safe, accessible, and compliant with international spacing standards.

| Zone | Dimensions | Requirement |

|---|---|---|

| Internal Play | 20m x 10m | Level, non-slip surface |

| Total Footprint | 22m x 12m | Room for pillars/lighting |

A correctly prepared site is the foundation of a successful padel installation and a long-lasting facility.

How long does a padel court manufacturer take?

A padel court manufacturer typically takes between 4 to 8 weeks to produce a custom court, followed by a logistical phase for shipping and local assembly. Your padel court manufacturer will provide a timeline that includes fabrication, transit, and the final onsite installation.

What factors can cause production delays?

Delays usually stem from custom color requests, raw material shortages, or high seasonal demand. Watch out for these:

- Non-standard RAL color powder coating.

- Shipping container availability.

- Local permit approval holdups.

How many days are required for onsite assembly?

Once the materials arrive and the base is ready, a professional crew can assemble a court very quickly. It happens fast.

- 3 to 5 days per court.

- 1 day for glass and mesh.

- 1 day for turf and silica sand.

Key Takeaway

Parallel tracking—preparing your foundation while the manufacturer builds the structure—is the most efficient way to open your club.

| Phase | Duration | Responsibility |

|---|---|---|

| Fabrication | 4-6 Weeks | Manufacturer |

| Installation | 3-5 Days | Assembly Team |

Clear communication with your manufacturer regarding lead times is essential for meeting your grand opening date.

How does a padel court manufacturer calculate costs?

A padel court manufacturer calculates costs based on the model type, material thickness, lighting specs, and the current price of global steel and glass. By requesting a quote from a padel court manufacturer, you can get a detailed breakdown of the logistical and construction expenses involved.

Which components require the most investment?

The structural steel and the high-performance tempered glass represent the largest portion of the manufacturing budget. Here is why:

- Hot-dip galvanization adds significant cost.

- 12mm panoramic glass is a premium material.

- Shipping bulky items requires specialized logistics.

What is the typical ROI for a commercial club?

Padel clubs generally see a fast return on investment due to the high density of players per square meter. Look at the numbers:

- Four players per 200sqm area.

- Lower water/electricity use than tennis.

- High court utilization rates in urban areas.

Key Takeaway

While the initial manufacturing cost is significant, the high revenue-per-square-foot makes padel one of the most profitable sports investments.

| Investment | Level | Revenue Driver |

|---|---|---|

| Court Structure | Moderate to High | Core playability |

| Lighting/Turf | Moderate | Night play and safety |

Budgeting for quality manufacturing upfront significantly reduces the long-term maintenance costs that eat into club profits.

How to maintain a padel court manufacturer build?

Maintaining a build from a padel court manufacturer requires regular cleaning of the glass, redistribution of the silica sand, and periodic checking of the structural bolts. A padel court manufacturer will often provide a maintenance manual to help you preserve the court’s performance and safety standards.

What is the lifespan of professional turf?

Professional turf typically lasts between 5 to 10 years, depending on the intensity of use and the quality of maintenance. Here is the deal:

- Weekly brushing prevents fiber matting.

- Keeping sand levels consistent protects roots.

- Monthly deep cleaning removes organic debris.

How often should glass and bolts be inspected?

Glass and structural connections should be inspected at least quarterly to ensure the facility remains safe for public use. Always check:

- Bolt tension on main pillars.

- Glass alignment and gasket condition.

- Net tension and lighting mast stability.

Key Takeaway

Proactive maintenance is the best way to protect your investment and ensure a consistent playing experience for your members.

| Task | Frequency | Impact |

|---|---|---|

| Sand Leveling | Bi-weekly | Consistent ball bounce |

| Glass Cleaning | Weekly | Professional aesthetic |

A well-maintained court not only looks better but also prevents the structural safety hazards associated with neglected hardware.

Building a world-class padel facility requires moving past the risks of poor planning and structural hazards that plague many new projects. By understanding the technical precision of the manufacturing process, you can avoid the agitation of shattering glass or subpar playing surfaces. Ensuring your facility is built to last starts with expert guidance and superior materials. To avoid safety risks and high maintenance costs, contact us today to begin your journey toward a profitable and durable sports investment.

Frequently Asked Questions

- Can I install a padel court on an existing outdoor tennis court?

Yes, but you must first evaluate the existing concrete or asphalt to ensure it can support the concentrated weight of the steel pillars and glass. In many cases, specific reinforcement points must be added to the existing base. - What’s the best way to choose between 10mm and 12mm glass?

While 10mm glass is suitable for standard models with full steel frames, 12mm glass is highly recommended for panoramic courts to ensure the necessary rigidity and safety in the absence of vertical supports. - Can I build an indoor padel club with low ceilings?

International standards require a minimum ceiling height of 7 meters, though 8 to 9 meters is the preferred standard for professional play to accommodate the high lobs that are central to the game. - What’s the best material for coastal padel court manufacturing?

Hot-dip galvanized steel with a specialized powder coating is the best choice for coastal areas, as it provides the highest level of protection against salt-air corrosion and oxidation. - Can I customize the colors of the turf and structure?

Yes, most manufacturers offer a wide range of RAL colors for the steel frame and various turf colors, including the traditional blue, green, and the increasingly popular clay red or black.