The cost of building a padel court typically ranges between $20,000 and $70,000 depending on your choice of premium materials and site requirements. You may find that navigating the technical and financial landscape of court construction feels overwhelming due to conflicting estimates and hidden site expenses. Without a clear roadmap, you risk investing significant capital into a facility that fails to meet professional standards or requires constant, expensive repairs. This guide provides a definitive breakdown of the cost of building a padel court to help you build a world-class facility efficiently.

What defines the initial cost of building a padel court?

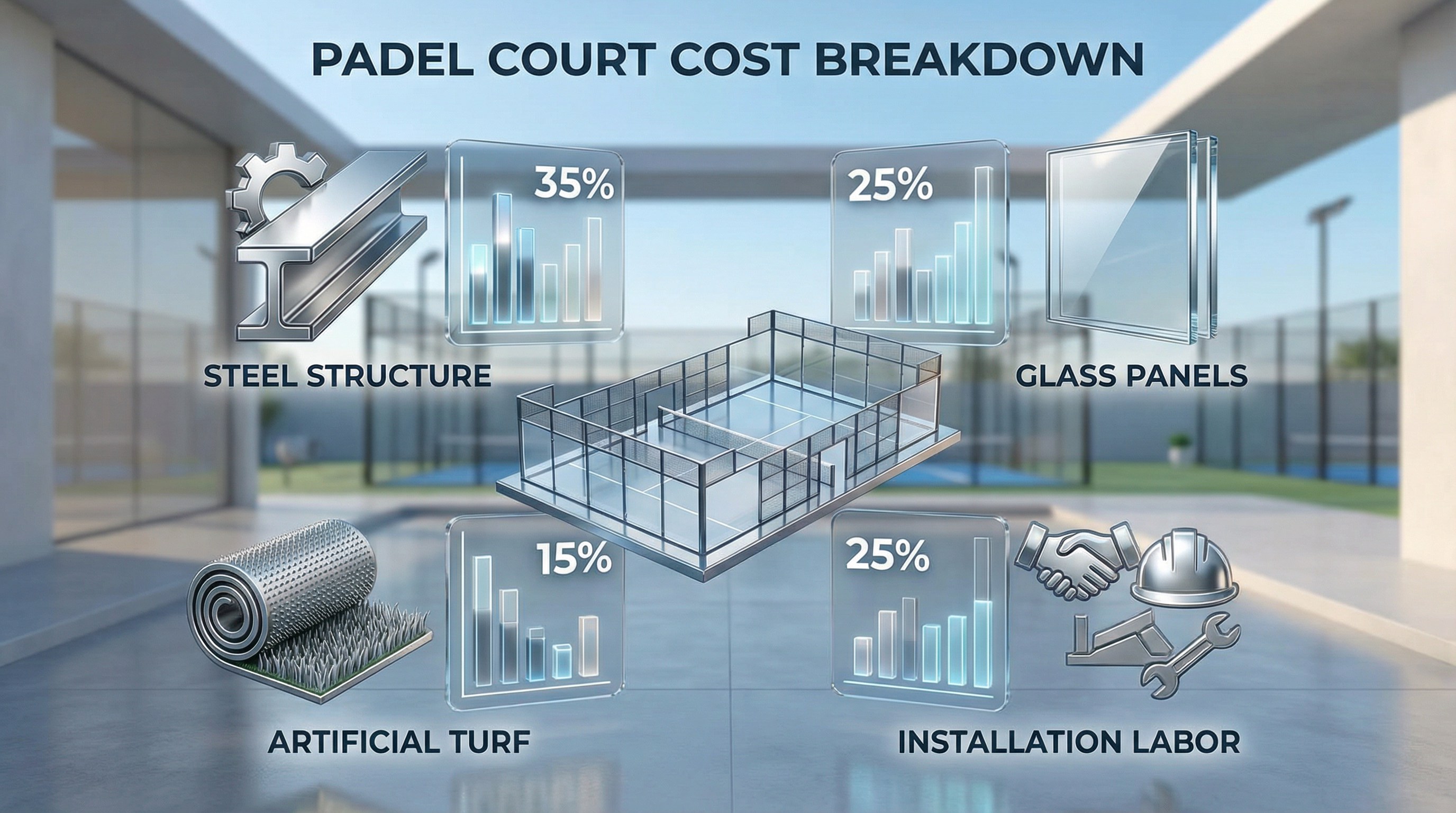

Structural components like galvanized steel frames and specialized glass panels define the primary investment for your project. The quality of these materials directly impacts the total cost of building a padel court from the start.

Core Structural Framework

The metal structure serves as the backbone of your court, requiring hot-dip galvanized steel to prevent rust. High-quality frames ensure that the court remains stable under heavy use and extreme weather conditions.

But that’s not all. You must also consider:

- Steel thickness and grade (typically Q235 or Q355).

- Mesh panel durability and welding quality.

- Electrostatic powder coating finishes for aesthetics.

Key Takeaway: Prioritizing high-grade steel reduces long-term maintenance overhead.

| Component | Cost Impact | Why it Matters |

|---|---|---|

| Steel Frame | High | Structural integrity and rust prevention |

| Glass Panels | Medium | Safety and ball rebound quality |

| Mesh Panels | Low | Playability and perimeter security |

Investing in a robust frame is the most critical step for a lasting facility.

How does logistics affect the cost of building a padel court?

Shipping fees and localized labor rates are primary external factors that shift the cost of building a padel court significantly. Because most professional components are transported in 40-foot containers, your distance from major ports matters.

Freight and Handling

Logistics involves more than just the ocean voyage; it includes local trucking and offloading at your site. You should prepare for fluctuating fuel surcharges and seasonal shipping spikes that can impact your budget.

Here’s the kicker:

- Port congestion can lead to storage fees.

- Specialized cranes may be needed for unloading.

- Duty and tax regulations vary by region.

Key Takeaway: Mapping out your supply chain early can save thousands in unexpected freight costs.

| Logistic Factor | Variable | Potential Savings |

|---|---|---|

| Port Proximity | High | Short-haul trucking discounts |

| Shipping Season | Medium | Off-peak booking rates |

| Import Duties | High | Local trade agreement benefits |

Careful planning of your delivery window is essential for budget control.

Is ground prep a major cost of building a padel court?

Foundation work is often the largest variable expense, as it accounts for a massive portion of the cost of building a padel court. A perfectly level 12cm to 15cm reinforced concrete slab is mandatory to prevent glass breakage.

Excavation and Leveling

The existing soil quality determines how much preparation your site requires before the concrete can be poured. If you are dealing with uneven terrain or soft soil, the excavation costs will climb quickly.

But wait, there’s more. Professional prep includes:

- Laser-guided leveling for a flat surface.

- Integrated drainage systems for outdoor builds.

- Sub-base compaction to prevent future sinking.

Key Takeaway: Cutting corners on the foundation leads to structural failure and unplayable surfaces.

| Prep Step | Cost Intensity | Benefit |

|---|---|---|

| Excavation | Medium | Clears site for stable construction |

| Concrete Slab | High | Provides the essential playing base |

| Drainage | Low-Medium | Protects turf from water damage |

A solid foundation ensures your court remains a viable asset for decades.

Why do materials change the cost of building a padel court?

High-performance materials like 12mm tempered glass and monofilament turf ensure durability, though they increase the cost of building a padel court initially. Choosing premium materials reduces the frequency of replacements and enhances the player experience.

Glass and Wall Systems

The thickness of your glass panels affects both the safety of the facility and the quality of the game. While 10mm glass is standard, 12mm tempered glass offers superior resistance to impact and better ball physics.

It gets better:

- Panoramic designs offer unobstructed views.

- Anti-corrosion coatings protect the fasteners.

- Specialized gaskets prevent glass-to-metal contact.

Key Takeaway: Investing in 12mm glass is the gold standard for commercial and high-end residential courts.

| Material | Option | Longevity Impact |

|---|---|---|

| Glass | 12mm Tempered | High safety and durability |

| Fasteners | Stainless Steel | Prevents rust staining on glass |

| Seals | UV-Resistant | Maintains structural grip over time |

Premium materials translate to a luxury feel that attracts more dedicated players.

Can turf quality impact the cost of building a padel court?

Turf density and the choice between monofilament or fibrillated fibers directly influence the long-term maintenance cost of building a padel court. The playing surface is where your players have the most contact, making quality paramount.

Surface Selection Criteria

Professional-grade turf requires a specific sand infill to ensure consistent ball bounce and player traction. Higher density turf resists the “matting” effect, keeping the court looking new for several years longer than budget options.

Don’t overlook this:

- Monofilament fibers offer the best recovery.

- Fibrillated turf is often more budget-friendly.

- Texture affects how the ball takes spin.

Key Takeaway: High-density monofilament turf is the best investment for high-traffic clubs.

| Turf Type | Initial Cost | Maintenance |

|---|---|---|

| Monofilament | Higher | Lower (resilient fibers) |

| Fibrillated | Lower | Higher (requires more brushing) |

| Texturized | Medium | Balanced playability |

Choosing the right surface ensures player satisfaction and reduces annual grooming needs.

What labor factors impact the cost of building a padel court?

Specialist installation teams and specialized equipment rentals are essential for meeting the structural safety standards included in the cost of building a padel court. Padel courts require precise alignment that general contractors may not be familiar with.

Expert Assembly Requirements

Installing large tempered glass panels and seamless turf requires specialized tools like heavy-duty suction lifters and turf seam cutters. A mistake during this phase can result in shattered glass or hazardous playing conditions.

Believe it or not:

- Expert teams can finish a court in 3-4 days.

- Scissor lifts are often required for lighting.

- Improper leveling during assembly voids warranties.

Key Takeaway: Hiring experienced padel installers prevents costly material damage during the build.

| Labor Element | Requirement | Risk of DIY |

|---|---|---|

| Glass Fitting | 2-3 Specialists | High (shattering risk) |

| Turf Seaming | 1 Specialist | Medium (tripping hazards) |

| Frame Leveling | Full Team | High (structural lean) |

Professional labor is an insurance policy for your significant capital investment.

Does slab thickness affect the cost of building a padel court?

Using a 15cm reinforced concrete base prevents structural shifting, but the additional material volume increases the cost of building a padel court. The slab must be a single, continuous pour to maintain a perfectly flat playing area.

Sub-base Stability

The concrete must be reinforced with steel mesh to handle the weight of the glass walls and the vibrations of the game. Without proper thickness, the slab can crack, leading to uneven glass and dangerous gaps.

Check this out:

- Curing time can take up to 21 days.

- Porous concrete helps with water runoff.

- Rebar placement is vital for structural tension.

Key Takeaway: A thicker slab is the best defense against ground movement and foundation cracks.

| Base Feature | Standard | Premium |

|---|---|---|

| Thickness | 12cm | 15cm+ |

| Reinforcement | Standard Mesh | Double Layer Rebar |

| Finish | Power Troweled | Laser-Leveled |

Ensuring the slab is done right the first time avoids total facility teardowns later.

How do design fees change the cost of building a padel court?

Architectural drawings and engineering stamps are necessary regulatory expenses that factor into the cost of building a padel court. Most commercial projects require these documents to secure building permits and ensure wind-load safety.

Permitting and Zoning

Your local municipality will likely require specific plans that show how the court impacts the surrounding environment. This includes geotechnical studies to confirm the soil can support the heavy concrete and steel structure.

The bottom line is:

- Zoning laws may restrict court height.

- Wind-load calculations are mandatory for glass.

- Soil tests prevent the slab from sinking.

Key Takeaway: Professional engineering stamps are required for most commercial insurance policies.

| Document Type | Necessity | Typical Cost |

|---|---|---|

| Soil Report | Mandatory | $1,000 – $3,000 |

| Wind-Load Calc | Mandatory | Variable by region |

| Site Survey | Highly Recommended | $500 – $1,500 |

Handling the legal paperwork upfront prevents work-stoppage orders during construction.

Can indoor setups lower the cost of building a padel court?

Indoor courts often bypass expensive drainage systems and UV-protection coatings, potentially lowering the environmental-protection portion of the cost of building a padel court. However, you must trade these savings for interior lighting and climate control expenses.

Climate-Controlled Benefits

Building indoors protects your turf and glass from the elements, which can double the lifespan of the playing surface. You also gain the ability to generate revenue 24/7, regardless of rain or snow.

Make no mistake:

- Ceiling height must be at least 7-8 meters.

- HVAC systems are needed for player comfort.

- Indoor lighting requires specific LUX levels.

Key Takeaway: Indoor facilities offer the highest ROI due to year-round playability.

| Environment | Outdoor | Indoor |

|---|---|---|

| UV Protection | Mandatory | Not Required |

| Drainage | Critical | Not Required |

| Playable Hours | Weather Dependent | 24/7 |

Indoor courts are more expensive to house but cheaper to maintain over time.

Does LED lighting increase the cost of building a padel court?

High-efficiency LED systems require a higher upfront spend but deliver massive long-term savings in the cost of building a padel court. Modern floodlights provide a crisp, white light that mimics daylight without the high energy consumption of older bulbs.

Energy Efficient Illumination

Selecting 200W or 240W LED lights ensures that players have perfect visibility during night matches. These lights are designed to be flicker-free, which is essential for high-speed racquet sports like padel.

The real story is:

- LEDs last over 50,000 hours.

- Integrated poles save on separate installation.

- Lower heat output protects the court frame.

Key Takeaway: LED lighting pays for itself through lower utility bills and zero bulb replacements.

| Light Type | Initial Cost | Power Usage | Lifespan |

|---|---|---|---|

| Traditional | Low | High | Short |

| Professional LED | Medium-High | Low | 5-10 Years |

| High-Output LED | High | Medium | 10+ Years |

Smart lighting choices ensure your court remains profitable during evening hours.

Strategic Conclusions

Building a padel court is a significant investment that requires balancing upfront quality with long-term operational costs. At Superb Padel, our vision is to provide developers and club owners with the most durable, factory-direct courts on the market, ensuring every dollar spent translates into a superior playing experience. We specialize in navigating the complexities of construction, from the initial slab pour to the final LED installation.

Let us help you transform your vision into a high-revenue sports facility. To learn more about our models or to get a custom quote for your project, contact us today.

Frequently Asked Questions

Can I build a padel court on an existing tennis court?

Yes, because the existing asphalt or concrete base often provides a sufficient foundation that drastically reduces excavation costs. You simply need to verify that the slab is level and structurally sound before anchoring the new frame.

What’s the best way to reduce shipping costs?

Order multiple courts at once. Since a single 40-foot container can often fit two complete court kits, you effectively cut your per-court logistics expense in half.

Can I install the court myself to save money?

No, because padel courts involve heavy tempered glass and precise structural tensioning that requires specialized equipment and training to ensure safety. Improper installation will void your material warranties and create liability risks.

What’s the best glass thickness for a commercial club?

Always choose 12mm tempered glass. It provides the most consistent ball rebound and the highest level of safety for high-traffic environments where player impacts are frequent.

Can I use standard outdoor floodlights for my court?

No, because padel requires specific “flicker-free” LED technology and a minimum LUX level to ensure ball visibility at high speeds. Standard lights often create shadows and glare that ruin the playing experience.