Padel turf is a specialized high-density synthetic grass system engineered for consistent ball bounce and player safety, and it is built by installing texturized polyethylene fibers over a level concrete sub-base and infilling them with kiln-dried quartz sand. Club owners and facility managers prioritize this surface because it eliminates the unpredictability of traditional courts and provides an all-weather solution that maximizes booking revenue. By following professional manufacturing standards, you can create a durable athletic environment that satisfies both amateur enthusiasts and professional athletes.

What exactly is modern padel turf?

Modern padel turf consists of high-quality polyethylene filaments that are texturized to hold sand infill and provide a uniform playing surface. These fibers are designed to mimic the performance of natural grass while offering the extreme mechanical resistance required for the high-impact lateral movements typical of the sport.

Why use synthetic fibers?

Synthetic fibers are used in padel courts because they offer superior durability and weather resistance compared to organic materials. The curly or “texturized” nature of these fibers is essential for keeping the silica sand stable and preventing the carpet from becoming slippery or uneven over time. Here is the kicker. Without this specific texturization, the sand would migrate to the edges of the court, leaving the center exposed to premature wear.

- Texturized Polyethylene: Provides the core resilience and “bounce back” ability.

- UV-Stabilized Yarn: Ensures the color and structure do not degrade under intense sun.

- High Tuft Density: Keeps the fibers upright to support the ball’s natural physics.

| Component | Material | Function |

|---|---|---|

| Surface Fiber | Polyethylene | Ball interaction and player grip |

| Primary Backing | Polypropylene | Structural foundation for tufting |

| Coating | Latex/Polyurethane | Secures fibers to the base |

Analyzing the composition of the fibers reveals that the balance between softness and mechanical strength is what defines a premium playing experience.

Why is padel turf better than clay courts?

Choosing padel turf over clay provides facility owners with an all-weather surface that requires significantly less daily labor to maintain. While clay requires constant watering, rolling, and line painting, synthetic systems remain ready for action immediately after rain or heavy use throughout the year.

Does it improve player safety?

Player safety is significantly enhanced by synthetic surfaces because they provide consistent shock absorption and predictable friction levels. A high-quality turf system reduces the impact stress on a player’s knees and ankles during the rapid stops and starts that define padel gameplay. Believe it or not. Players are much less likely to suffer from joint fatigue on a padded synthetic surface than on hard courts or poorly maintained clay.

- Impact Absorption: The multi-layer system cushions every step.

- Controlled Sliding: Silica sand allows for safe, controlled slides without catching.

- Surface Uniformity: Eliminates the “dead spots” or holes common in clay.

| Surface Feature | Synthetic Turf | Traditional Clay |

|---|---|---|

| Daily Maintenance | None required | High (Watering/Leveling) |

| Playable Post-Rain | Immediate | Delayed |

| Average Lifespan | 8-10 Years | Variable (High upkeep) |

The transition to synthetic surfaces has become the industry standard because it directly correlates with higher player retention and lower operational overhead.

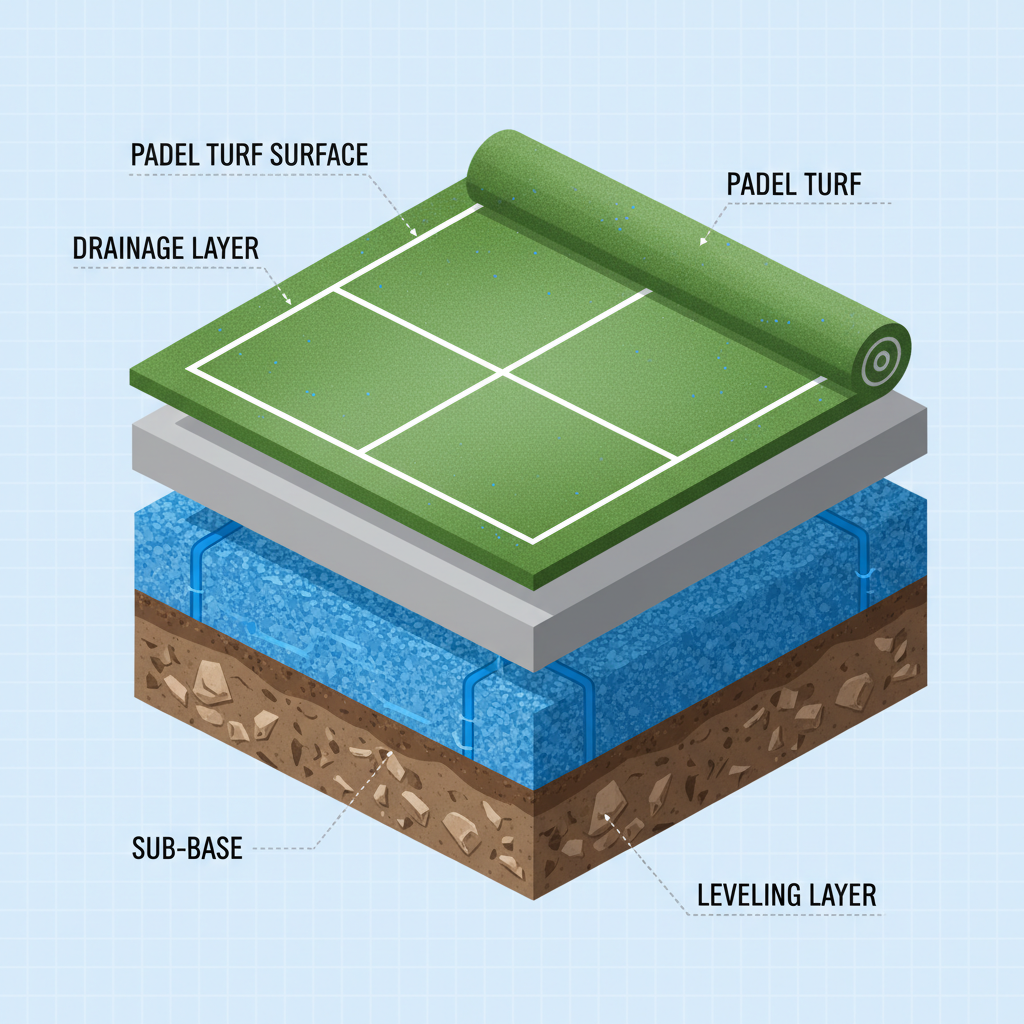

What are the technical layers within padel turf?

The technical layers of padel turf involve a complex stack including the polyethylene yarn, a reinforced polypropylene backing, and a secondary coating to lock the fibers in place. This multi-layered architecture is designed to prevent the carpet from stretching, shrinking, or shedding fibers under the intense mechanical stress of competitive matches.

How does drainage work?

Drainage in modern turf systems works through a series of micro-perforations in the backing that allow water to pass vertically into the sub-base at high speeds. This engineering ensures that even during heavy downpours, the court does not accumulate puddles that could displace the sand infill or damage the fibers. Ready for the good part? Most professional systems can handle drainage rates exceeding 30 liters per minute per square meter, making them virtually flood-proof.

- Micro-perforations: Holes spaced strategically to allow water flow.

- Porous Backing: Materials that do not trap moisture against the concrete.

- Angled Sub-base: A slight gradient often assists in moving water toward the perimeter.

| Layer | Material Type | Performance Benefit |

|---|---|---|

| Fiber | Texturized PE | Wear resistance and aesthetics |

| Backing | Reinforced PP | Dimensional stability |

| Sealant | PU / Latex | Maximum tuft lock strength |

Evaluating these technical layers is crucial for ensuring that the court remains stable and functional in diverse climatic conditions.

How do you choose the right padel turf density?

Choosing the right density for your padel turf depends on the expected level of foot traffic and the desired speed of play. A high-density carpet, typically ranging from 50,000 to 60,000 stitches per square meter, provides better fiber support and requires less frequent sand redistribution.

Is fibrillation better than monofilament?

Fibrillated fibers are often preferred for commercial clubs because their honeycomb structure holds the sand infill more effectively than monofilament alternatives. While monofilament fibers provide a more “natural” grass look, fibrillated turf is renowned for its durability and ease of maintenance over many years of heavy use. Wait, there is more. Many professional tournaments are now moving toward monofilament for its elite aesthetic, though it requires more meticulous sand grooming.

- Fibrillated: High sand retention and lower maintenance.

- Monofilament: Superior aesthetics and high fiber resilience.

- Stitch Count: Higher counts (e.g., 63,000) offer the longest lifespan.

| Density Grade | Stitches/sqm | Usage Intensity |

|---|---|---|

| Club Grade | 52,500 | Daily heavy use |

| Pro Grade | 63,000 | Tournaments and elite clubs |

| Standard | 42,000 | Private residential use |

High stitch density is the single most important factor in determining how well the court will stand up to the rigors of back-to-back bookings.

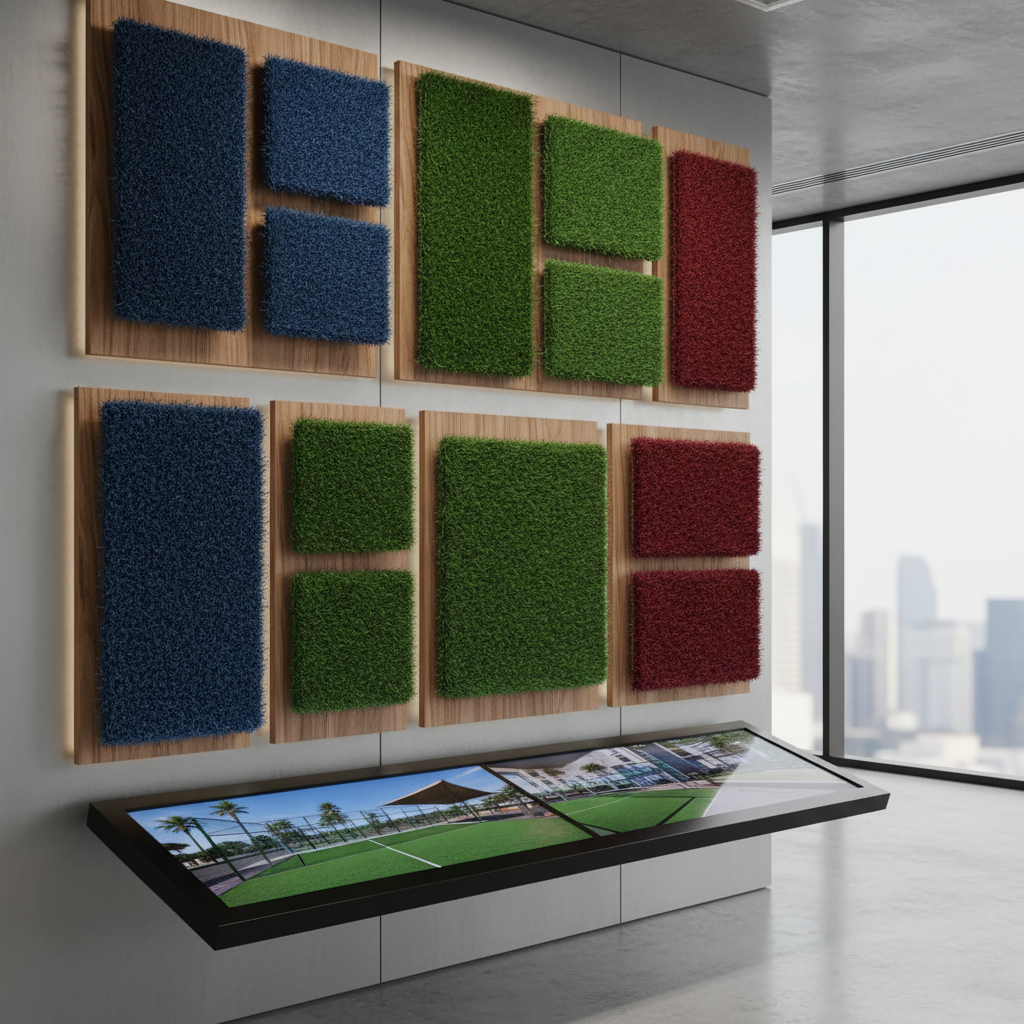

Which colors are available for professional padel turf?

Professional padel turf is available in a wide spectrum of colors, including electric blue, classic green, and terracotta, to suit different branding and visibility needs. While blue has become the global standard for televised professional matches, green remains a top choice for clubs that want a more traditional athletic appearance.

Why is blue the standard?

Blue is the industry standard for tournaments because it provides the highest visual contrast against the yellow padel ball, allowing players and spectators to track movement with ease. This high-contrast environment reduces eye strain and helps referees make more accurate calls during fast-paced points. The kicker? Blue also looks significantly better on digital broadcasts and social media, which helps clubs market their facilities more effectively.

- Electric Blue: Optimized for television and high-end branding.

- Classic Green: Blends perfectly with outdoor resort environments.

- Terracotta/Red: Offers a unique, clay-like aesthetic with synthetic benefits.

| Color Choice | Contrast Level | Popularity |

|---|---|---|

| Electric Blue | Highest | Industry Standard |

| Forest Green | High | Traditional / Outdoor |

| Terracotta | Medium | Niche / Design-focused |

Selecting a vibrant, high-contrast color is a strategic move that enhances both the player experience and the facility’s marketability.

Installing premium padel turf correctly requires a perfectly level sub-base and a precise seaming process to ensure the carpet remains flat and secure. Professionals use specialized adhesive tapes and two-part glues to join the rolls of grass, creating a seamless surface that mimics a single, continuous piece of turf.

What about the quartz sand infill?

Quartz sand infill is the final and most critical component of the installation, providing the weight necessary to keep the carpet in place and the grip required for play. It must be applied using a mechanical spreader to ensure a perfectly even depth of 15-20kg per square meter across the entire court surface. But wait, there is more. Using kiln-dried sand prevents clumping during the initial application, ensuring the sand reaches the bottom of the fibers immediately.

- Leveling: The sub-base must have less than 3mm of deviation.

- Seaming: Uses high-strength tape to prevent trip hazards.

- Brushing: The final step to lift fibers and settle the sand.

| Installation Step | Critical Tool | Goal |

|---|---|---|

| Sub-base Prep | Laser Level | Perfect Flatness |

| Seaming | Two-part Adhesive | Permanent Bond |

| Infilling | Power Brusher | Even Sand Distribution |

A meticulous installation process is the only way to guarantee the long-term structural integrity and playability of a professional court.

How much does professional padel turf cost?

The cost of professional padel turf varies based on fiber quality, density, and shipping logistics, but purchasing factory-direct can save facility owners up to 30% on material costs. By cutting out middleman markups, investors can reallocate their budget toward higher-quality glass walls or advanced LED lighting systems.

Can you buy factory direct?

Buying factory-direct is highly recommended for B2B clients because it ensures you receive the latest fiber technology and a direct warranty from the manufacturer. It also allows for full customization of colors and logos, which is often restricted when buying from local retail distributors. You might be wondering. Does buying cheaper turf save money in the long run? Generally, the answer is no, as low-cost options often require replacement within 3-4 years, doubling your total investment.

- Bulk Discounts: Ordering for multiple courts significantly lowers the per-unit cost.

- Custom Branding: Add your club’s logo directly into the turf weave.

- Logistics: Direct shipping minimizes the risk of damage during multiple transfers.

| Sourcing Model | Typical Cost | Quality Control |

|---|---|---|

| Retail Distributor | High | Secondary |

| Factory Direct | Optimized | Primary |

| Local Reseller | Moderate | Variable |

Analyzing the total cost of ownership rather than just the initial price tag is the key to a profitable sports facility investment.

How do you maintain padel turf for longevity?

Maintaining padel turf for longevity involves a consistent routine of brushing the surface to keep the fibers upright and the sand evenly distributed. Without regular grooming, the sand will compact in high-traffic areas, leading to a “hard” feel that increases player joint impact and accelerates fiber wear.

Should you brush the surface?

Brushing the surface weekly is essential for preventing the sand from hardening and ensuring that the drainage holes remain clear of organic debris. A mechanical power brush is the most efficient tool for this task, as it penetrates deep into the pile to lift fibers that have been flattened by heavy gameplay. The best part? Regular brushing only takes about 30 minutes per court but can extend the life of your synthetic grass by several years.

- Weekly Brushing: Realigns fibers and redistributes sand.

- Daily Cleaning: Removes leaves and trash that can block drainage.

- Annual Deep Clean: Removes fine dust particles from the infill.

| Task | Frequency | Impact |

|---|---|---|

| Surface Brushing | Weekly | Prevents fiber matting |

| Debris Removal | Daily | Maintains drainage |

| Sand Top-up | Bi-Annually | Ensures stability |

Establishing a proactive maintenance schedule is the most effective way to protect your capital investment and keep players coming back.

What are the drainage requirements for padel turf?

Drainage requirements for padel turf dictate that the system must handle vertical water flow effectively to prevent the accumulation of moisture within the sand layer. A properly engineered system features a porous sub-base and a perforated carpet backing that allows the court to return to a playable state within minutes of a storm ending.

Does it work in heavy rain?

High-performance synthetic systems are specifically designed to work in heavy rain, provided the sub-base has been constructed with the correct porosity and slope. Unlike natural surfaces that become muddy and unusable, synthetic turf maintains its structural integrity and grip even when saturated with water. What is the real story? The secret lies in the interaction between the rounded quartz sand and the polyethylene fibers, which do not absorb moisture or change texture when wet.

- Vertical Permeability: Allows water to exit through the base quickly.

- Non-absorbent Fibers: Polyethylene stays light and responsive when wet.

- Sand Stability: Rounded grains prevent “clumping” during drainage.

| Environmental Factor | Impact | Solution |

|---|---|---|

| Heavy Downpour | Potential Puddling | High-flow micro-perforations |

| Humidity | Moss/Algae Growth | Regular brushing and drainage |

| Standing Water | Sand Displacement | Correct sub-base gradient |

Effective water management is the foundation of year-round court availability and consistent facility profitability.

Why is UV resistance vital for padel turf?

UV resistance is vital for padel turf because intense solar radiation can cause synthetic fibers to become brittle and lose their vibrant color over time. Manufacturers incorporate UV stabilizers directly into the polymer matrix during the extrusion process to ensure the protection is permanent and consistent throughout the fiber’s lifespan.

Will the colors fade?

Colors will not fade significantly if the turf is treated with high-grade UV stabilizers that are designed to withstand the equivalent of 10+ years of direct sunlight. Professional-grade surfaces undergo rigorous Xenon arc testing to prove they can maintain their structural flexibility and hue even in high-heat regions like the Middle East or Southern Europe. Ready for the good part? Choosing a UV-protected system ensures that your court remains a beautiful, high-value centerpiece for your club without needing premature replacement.

- Stabilizer Integration: Protection is built-in, not just a coating.

- Fiber Flexibility: Prevents the grass from breaking off into dust.

- Color Fastness: Maintains high-contrast blue or green for a decade.

| Protection Level | Benefit | Result |

|---|---|---|

| High UV Rating | Color Retention | Consistent Branding |

| Polymer Stability | No Brittleness | Long Lifespan |

| Heat Resistance | Dimensional Stability | No Wrinkles |

Investing in UV-resistant materials is a non-negotiable requirement for any outdoor padel facility aiming for long-term operational success.

*

Strategic Guidance for Facility Owners

Building a world-class padel facility requires a commitment to technical excellence and high-quality materials. By selecting high-density padel turf, ensuring precise installation over a level base, and maintaining a strict grooming schedule, you can create a sports environment that thrives for over a decade. The combination of synthetic durability and advanced fiber technology provides the best possible return on investment for club owners. If you are ready to begin your construction journey with the industry’s best materials, contact us today for a professional consultation and custom quote tailored to your project.

Frequently Asked Questions

Can I install padel turf over an existing tennis court?

Yes, as long as the existing surface is level and structurally sound, you can install new synthetic turf directly over it after a thorough cleaning.

What’s the best way to clean the court surface?

The best method is regular brushing to redistribute sand and using a leaf blower daily to remove organic debris that could clog the drainage holes.

Can I customize the turf with my club’s logo?

Absolutely, we provide OEM services where your logo can be woven directly into the synthetic grass during the manufacturing process for a professional look.

What’s the best sand to use for the infill?

The best option is kiln-dried, rounded quartz sand (silica) with a grain size between 0.2mm and 0.8mm to protect the fibers from abrasion.

Can I order a single court for a private residence?

Yes, we accommodate all order sizes and can ship a complete court package including turf, glass, and structure to any location worldwide.