The best padel balls are pressurized rubber spheres covered in felt that are built through a high-precision molding process followed by bonding a specific weave of wool and synthetic fibers.

Many club owners struggle with rapid ball deflation and inconsistent bounce that ruins the player experience. If your equipment fails mid-match, your reputation as a premium facility suffers and costs skyrocket due to frequent replacements. The solution lies in sourcing the best padel balls designed with advanced core retention technology to ensure longevity and peak performance.

What defines the best padel balls for professional play?

High-quality rubber cores and optimal internal pressure define the standard for professional-grade equipment. Using the best padel balls ensures that the game remains fast and the bounce remains predictable throughout high-intensity sets. These balls must meet strict weight and diameter specifications to be certified for official competition.

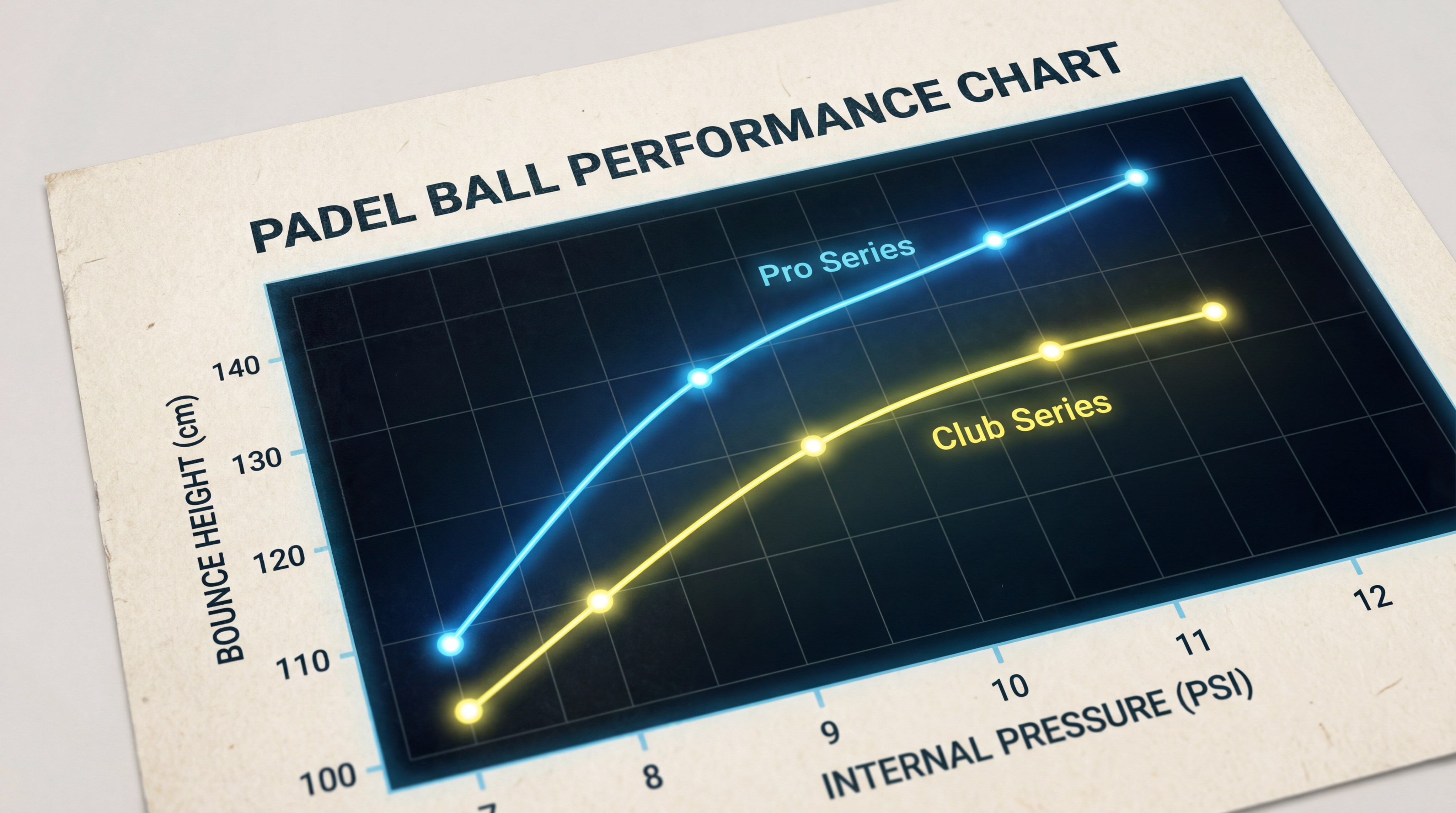

Why does pressure matter for pros?

Internal pressure dictates the rebound height and speed of the game on a standard padel court. If the pressure is too low, the ball becomes heavy and sluggish, frustrating advanced players who rely on power.

Look:

- Consistent rebound height

- Faster flight speed

- Predictable ball trajectory

Key Takeaway: Professional play requires strict pressure adherence to maintain game integrity and player satisfaction.

| Performance Metric | Professional Standard |

|---|---|

| Internal Pressure | 10 PSI – 11 PSI |

| Rebound Height | 135 cm – 147 cm |

| Durability Rating | High Impact Resistance |

High internal pressure is the primary driver for the fast-paced responsiveness required in professional tournaments.

How are the best padel balls manufactured for durability?

The manufacturing process involves vulcanizing natural rubber into two half-shells before joining them under high-pressure conditions. To create the best padel balls, manufacturers use automated lines to ensure wall thickness remains perfectly uniform across every batch. This consistency prevents “wobble” during flight and ensures a true bounce every time.

Can you automate quality control?

Robotics ensure that the bonding agent is applied evenly across the rubber core. This is vital when learning how to build a padel court or stocking a new facility with reliable gear. Automation allows for thousandths-of-an-inch precision that human assembly simply cannot match.

The best part?

- Automated molding for symmetry

- Precise weight verification

- Uniform felt application

Key Takeaway: Durability is a direct result of automated precision in the rubber vulcanization and bonding stages.

| Manufacturing Stage | Quality Benefit |

|---|---|

| Vulcanization | Structural Integrity |

| Automated Bonding | Leak Prevention |

| Robotic Felt Wrap | Aerodynamic Balance |

Automation removes human error from the weight and balance equation, leading to a more durable product.

Which materials make up the best padel balls core?

A blend of high-grade natural rubber and specific chemical stabilizers forms the core of top-tier sports equipment. Selecting the best padel balls requires an understanding of how these chemical compounds prevent air molecules from escaping through the rubber membrane. A denser core maintains its “pop” for several more matches than cheaper alternatives.

Is natural rubber better for courts?

Natural rubber provides the elasticity needed for the ball to compress and rebound against a glass wall. Synthetic additives are then mixed in to strengthen the structure against repetitive high-impact shots. This material choice is crucial for maintaining performance on a panoramic padel court where wall play is constant.

But here is the kicker:

- Superior core elasticity

- Enhanced tensile strength

- Long-term air retention

Key Takeaway: A high-density rubber core is the foundation of a ball that resists softening during aggressive play.

| Material Component | Primary Function |

|---|---|

| Natural Rubber | Rebound Elasticity |

| Chemical Stabilizers | Air Leakage Control |

| Synthetic Polymers | Shell Reinforcement |

The specific ratio of rubber to stabilizers determines the long-term playability and “feel” of the core.

How do the best padel balls differ from tennis balls?

While they look identical, the best padel balls have significantly lower internal pressure and a slightly different felt thickness. Choosing the best padel balls is essential because using a tennis court ball in a padel match leads to an uncontrollably high bounce. This can lead to injuries and a degraded gaming experience due to the faster pace.

Why the pressure difference?

Padel balls are pressurized to roughly 11psi, whereas tennis balls often exceed 14psi. This difference is designed to account for the smaller court size and the presence of walls. The lower pressure allows for better control during the short-range exchanges typical of the sport.

Listen:

- Lower bounce height

- Slower flight speed

- Thicker felt weave

Key Takeaway: Pressure regulation is the technical factor that truly separates these two similar-looking sports accessories.

| Feature | Padel Ball | Tennis Ball |

|---|---|---|

| Internal Pressure | ~11 PSI | ~14 PSI |

| Rebound (2.54m drop) | 135-147 cm | 135-147 cm |

| Diameter | 6.35 – 6.77 cm | 6.54 – 6.86 cm |

Padel balls are engineered specifically for the unique rebound physics of enclosed glass environments.

What felt type is used for the best padel balls?

Premium felt is typically a woven mixture of wool, cotton, and nylon designed to provide the ultimate grip on the racket face. The best padel balls utilize a higher wool content to improve aerodynamic drag and allow players to apply more spin. Cheaper balls often use needle-punched felt which wears down much faster.

Does wool content matter for spin?

Higher wool percentages result in a “fuzzier” ball that grips the turf of a professional court better. Synthetic fibers are added to the mix primarily to enhance the abrasion resistance of the outer shell. This balance is critical for maintaining performance over multiple sets.

The best part?

- Increased spin potential

- Better speed control

- Enhanced surface durability

Key Takeaway: A high wool-to-synthetic ratio is the secret behind professional-level spin and flight control.

| Felt Material | Benefit |

|---|---|

| Natural Wool | Friction and Grip |

| Nylon Fibers | Abrasion Resistance |

| Cotton Blend | Softness and Feel |

Balancing natural wool for grip and nylon for durability is the hallmark of a premium sports ball.

How is pressure maintained in the best padel balls?

Manufacturers use specialized pressurized canisters to prevent the internal gas from leaking through the rubber pores before use. The best padel balls are packed in these airtight tubes at a pressure matching their internal PSI. This ensures that the balls remain in a state of equilibrium until the seal is finally broken.

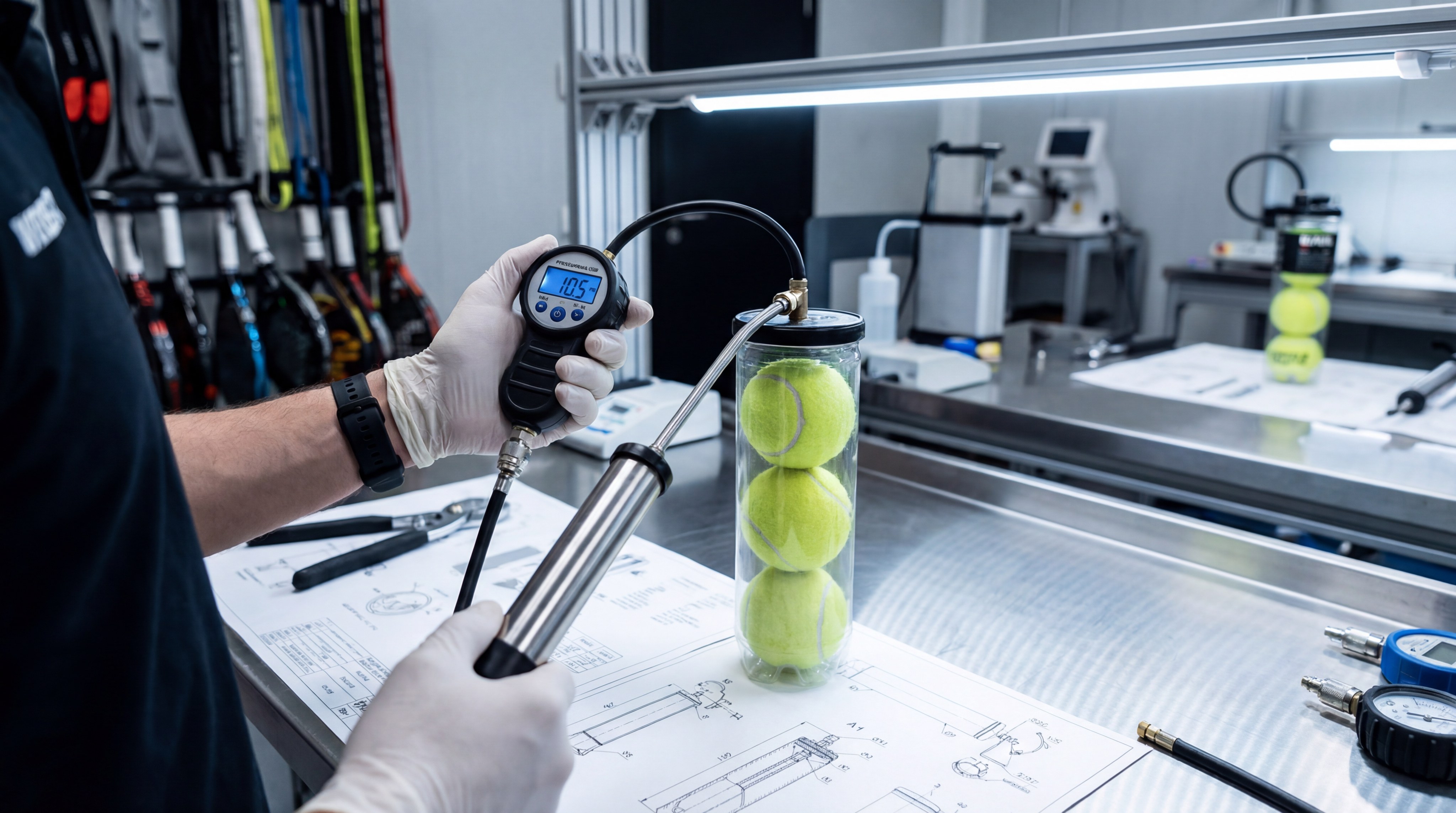

How to check ball pressure?

You can use a digital gauge or a simple bounce test to verify if the balls are still fit for play. Maintaining optimal pressure is just as important as knowing how to build a padel court correctly for a high-end club. Without proper pressure, the ball loses its characteristic “snap” off the racket.

But here is the kicker:

- Pressure-matched tubes

- Regular bounce tests

- Visual felt inspection

Key Takeaway: Hermetic sealing in the packaging phase is mandatory to prevent the balls from going “dead” on the shelf.

| Storage Tool | Purpose |

|---|---|

| Pressurized Canister | Factory Freshness |

| Digital PSI Gauge | Accuracy Testing |

| Pressure Saver | Life Extension |

Proper packaging ensures the product remains factory-fresh until the very moment the player opens the tube.

Where should you store the best padel balls for longevity?

Storing your equipment in a climate-controlled environment with stable humidity is the most effective way to extend gear life. Even the best padel balls will degrade quickly if exposed to extreme temperature fluctuations that cause gas expansion. Always keep your inventory away from direct sunlight or damp basement floors.

Is temperature critical for rubber?

Heat increases internal pressure, which can lead to permanent deformation of the rubber core over time. Conversely, cold weather makes the ball feel heavy and unresponsive on a standard padel court. Maintaining a steady room temperature is the gold standard for club storage.

Look:

- Dark storage areas

- Room temperature settings

- Low humidity environments

Key Takeaway: Climate control is the most underrated factor in preserving ball bounce and felt integrity for your members.

| Condition | Impact on Ball |

|---|---|

| High Heat | Core Deformation |

| Extreme Cold | Reduced Elasticity |

| High Humidity | Felt Weight Increase |

Stable environments prevent the physical breakdown of both the internal rubber and the external felt fibers.

What impact does altitude have on the best padel balls?

High-altitude locations require balls with lower internal pressure to compensate for the thinner air and reduced atmospheric resistance. Choosing the best padel balls specifically designed for altitude ensures that the game doesn’t become too fast. Using sea-level balls at high altitudes results in balls flying out of the court too easily.

Should you change balls for altitude?

In cities high above sea level, a standard ball will fly much further and bounce higher than intended. This makes technical play on a panoramic padel court difficult without specialized low-pressure equipment. Altitude-specific balls are usually marked with an “S” or “High Altitude” label.

The best part?

- Altitude-specific cores

- Reduced internal PSI

- Increased felt drag

Key Takeaway: Altitude-specific balls allow for a consistent gaming experience regardless of your facility’s geographic location.

| Location Type | Recommended Ball |

|---|---|

| Sea Level | Standard Pressure |

| >1200m Altitude | Low Pressure (S-Type) |

| Indoor Controlled | Standard Pressure |

Lowering internal PSI at high altitudes restores the intended game physics and improves player control.

How does impact speed affect the best padel balls?

High-velocity impacts cause the rubber core to momentarily deform, converting kinetic energy into heat and rebound force. The best padel balls are engineered to recover their shape instantly, ensuring that consecutive shots remain consistent. This structural memory is what allows for the high-speed “vibora” shots common in pro matches.

Does the core heat up?

Repeated smashing generates friction and heat within the core, which can slightly increase bounce during a long rally. This is why professional players often change balls after a set number of games on a tennis court conversion. High-quality rubber dissipates this heat more efficiently than low-grade materials.

Listen:

- Rapid deformation recovery

- Efficient heat dissipation

- Strong structural memory

Key Takeaway: Rapid shape recovery is what differentiates premium cores from cheap, low-quality gear.

| Impact Variable | Effect |

|---|---|

| High Speed Smash | Temporary Compression |

| Continuous Play | Internal Heat Build-up |

| Off-Center Hit | Core Shear Stress |

Structural memory ensures the ball performs identically from the first serve to the final match point.

Why invest in the best padel balls for your club?

Investing in premium equipment reduces long-term operational costs by decreasing the frequency of ball replacements. Providing the best padel balls signals to your clients that your facility offers a professional environment. This attention to detail often justifies a higher court rental fee and improves member retention.

Does it help member retention?

Players are more likely to return to a club where the equipment is in top condition and the bounce is reliable. When you combine high-quality balls with knowledge of how to build a padel court, you create a market-leading destination. High-quality balls are a small investment that yields a massive return in player satisfaction.

The best part?

- Better member retention

- Lower annual waste

- Enhanced club reputation

Key Takeaway: Premium equipment is a marketing tool that pays for itself through increased player loyalty and word-of-mouth.

| Investment Factor | ROI Impact |

|---|---|

| Ball Longevity | Reduced OPEX |

| Player Experience | Higher Retention |

| Brand Perception | Premium Pricing |

The cost-per-play of premium balls is significantly lower when considering their extended lifespan and performance.

High-performance sports equipment is about more than just aesthetics; it is about engineering a perfect player experience that keeps your courts full. We focus on solving your facility’s most pressing equipment challenges through innovation, durability, and uncompromising quality standards. Our vision is to empower club owners with the elite tools and knowledge they need to lead the competitive padel industry. Please contact us today to find out how we can elevate your facility with the best gear available on the market.

FAQ

Can I use tennis balls on a padel court?

No, because tennis balls have higher internal pressure and will bounce too aggressively off the glass walls for fair play.

What’s the best way to tell if a ball is dead?

Perform a simple drop test from 2.54 meters; if it fails to bounce between 135cm and 147cm, it has lost its pressure.

How do I know if my balls are altitude-ready?

Check the packaging for a specific “S” or “Altitude” designation which indicates the ball has been manufactured with lower internal PSI.

Can I repressurize old padel balls?

Yes, by using specialized pressure-saver canisters that force air back into the rubber core over several days of storage.

What’s the best felt for humid climates?

Synthetic-heavy blends are superior in high humidity because they absorb less moisture and maintain their weight during long matches.