Padel represents a high-speed social racquet sport played within a four-walled glass enclosure that combines elements from tennis and squash. Traditional sports facilities often struggle with low engagement rates while modern athletes seek interactive experiences that foster community alongside physical fitness. You can solve this occupancy problem by installing high-density courts that maximize player throughput per square meter. Our factory provides premium what is padel solutions that transform empty spaces into profitable community hubs through expert engineering. Investors frequently notice vacant tennis zones while these vibrant glass cages remain fully booked throughout every evening session across major cities. High demand creates a massive supply gap which costs your business potential revenue every single day until you adapt.

- What is padel history and global origin?

Padel originated within Mexico during 1969 when Enrique Corcuera constructed a small court featuring walls at his private vacation residence. Understanding what is padel requires looking back at how this wealthy innovator modified his home space for racket games. He wanted a fun activity for guests that prevented balls from rolling into the dense tropical garden. This clever adaptation birthed a new discipline that eventually migrated across the Atlantic Ocean toward Spanish resorts. Elite circles embraced this activity because it offered intense rallies without the exhausting running required on large grass courts. Today millions of active players follow the professional circuit while global expansion continues at a breathtaking pace.

Padel began as a localized luxury pastime but quickly transformed into a legitimate competitive sport with standardized rules and international federations. Early adopters noticed how the wall rebounds added a layer of strategic depth that traditional tennis lacked. You should appreciate that the original cement floors have since evolved into high-tech synthetic turf surfaces. These modern materials provide better shock absorption for players who compete at high intensity during long matches. The game maintains its reputation for being extremely inclusive because children and seniors can play together effectively. Social bonding happens naturally because four people occupy a relatively small area during every point.

The Mexican foundation of Corcuera

Think about it:

● Construction of the first wall-assisted court

● Evolution of the solid wooden racquet

● The transition from Mexico to Marbella

Viviana Corcuera played a major role in promoting the sport among socialites who visited their Acapulco home during the summer. The original court measured twenty meters long while the width stayed at ten meters to fit the garden space. Her influence helped the game spread among celebrities who sought private yet engaging activities away from public view. This legacy continues today as many clubs name their center courts after the Corcuera family.

Global expansion and professionalization

You see,

● The 1974 introduction to Spanish royalty

● Formation of the first international federations

● Launch of the World Padel Tour

Spain became the epicenter for growth as Prince Alfonso built two courts at the Marbella Club after visiting Mexico. Thousands of courts now populate every major Spanish town because the climate suits year-round outdoor play. You will find that South America also holds a massive player base with Argentina producing many top-ranked professionals. The sport gained official recognition as cameras could finally capture the action through transparent glass walls.

Modern technical standards for clubs

What’s the real story?

● Standardized twenty-by-ten meter dimensions

● Universal rules for service and scoring

● Requirements for international tournament approval

Professional organizations established strict criteria for court specifications to maintain consistency across different countries and continents. Every padel court must now feature specific mesh wire patterns that allow for predictable ball bounces during fast rallies. You need to follow these guidelines if you plan on hosting official league matches at your new facility. Proper adherence to global standards ensures that your investment retains its value as the sport grows.

| Feature | Original Spec | Modern Standard |

|---|---|---|

| Wall Material | Solid Brick/Cement | 12mm Tempered Glass |

| Floor Surface | Hard Concrete | Synthetic Turf with Sand |

| Racket Type | Solid Wood | Carbon Fiber Composite |

| Court Width | Variable | Exactly 10 Meters |

The historical transition from private hobby to global industry proves that social engagement remains the primary driver for athletic success.

Key Takeaway: Padel offers high engagement because the learning curve remains very low for beginners while offering deep strategy for advanced athletes.

- What is padel court size and layout?

Padel court dimensions measure exactly ten meters wide by twenty meters long for the interior playing surface. Knowing what is padel geometry helps you plan your site efficiently to maximize the number of courts per hectare. You must include a small clearance zone around the perimeter to allow for safe player movement outside the cage. Professional facilities often leave four meters of extra space at the sides for spectacular out-of-court ball recoveries. This layout ensures that the glass walls stand tall at three meters while the fence adds another meter of height. Accurate marking of the service lines keeps the game fair and competitive for all skill levels.

Padel layouts usually follow a grid pattern that allows spectators to move between courts without interrupting active matches. You should consider the orientation of your facility to avoid sun glare during the sunset hours which ruins player visibility. North-south alignment remains the preferred choice for outdoor installations to keep the light consistent across the turf surface. Each court requires a total footprint of roughly two hundred twenty square meters when including the metal structural supports. Proper spacing between cages prevents noise interference and allows for easy maintenance access with cleaning equipment. High-end clubs often add seating areas between courts to enhance the social atmosphere for waiting players.

Interior playing area specifications

Ready for the good part?

● The ten-by-twenty meter internal rectangle

● Central net height of eighty-eight centimeters

● Service lines positioned at seven meters

The net divides the court into two equal squares of ten by ten meters where players move in pairs. You will notice that the service boxes are larger than tennis boxes to accommodate the underhand serve style. Maintaining these exact measurements is necessary for professional certification and player satisfaction during league play. Any deviation from the standard size will affect the ball trajectory and timing of the rebounds.

Exterior safety and clearance zones

Here’s the deal,

● Minimum three-meter side clearance requirements

● Out-of-court play zones for tournaments

● Structural support post placement logic

Safety remains a top priority when you design a high-traffic sports club with multiple adjacent courts. Players often sprint through the side doors to return balls that bounce over the fence during intense rallies. You must provide enough buffer space to prevent collisions with other court structures or spectator benches. This extra room also helps with the installation of the lighting poles which require solid ground foundations.

Vertical wall and fence heights

This is where it gets interesting…

● Three-meter high glass panels at the back

● Four-meter high mesh fencing on the sides

● Tolerance levels for structural wind loads

The vertical profile of the court creates the “cage” feeling that makes the sport so unique and exciting. Glass walls must be perfectly aligned to ensure that the ball bounce remains true across the entire surface. You will find that the side mesh allows for airflow which keeps players cool during hot summer matches. These height standards are fixed across all professional standard padel court designs to ensure universal playability.

| Measurement | Dimension | Purpose |

|---|---|---|

| Total Length | 20.00 Meters | Playing Area Limit |

| Total Width | 10.00 Meters | Sideline Boundary |

| Back Wall Height | 3.00 Meters | Glass Rebound Zone |

| Side Fence Height | 4.00 Meters | Perimeter Protection |

Correct site layout prevents operational bottlenecks and improves the overall safety profile of your commercial sports venture.

Key Takeaway: Standardized dimensions ensure that players can transition between different clubs without losing their rhythm or technical accuracy.

- What is padel vs tennis racket design?

Padel rackets feature a solid hitting surface with holes rather than the strings found on traditional tennis models. Explaining what is padel gear involves highlighting the short handle that gives players superior control during fast net exchanges. You will feel that these rackets are much heavier but smaller than their tennis counterparts which facilitates quick movements. Manufacturers use advanced carbon fiber or fiberglass composites to create a balance between power and vibration dampening. The core usually contains EVA foam that compresses upon impact to absorb the shock of the ball hitting the frame. This unique construction allows for the spinning shots that define high-level competitive play.

Padel balls look very similar to tennis balls but they have slightly less internal pressure to slow the game down. You should understand that this reduced pressure keeps the ball within the small court area during powerful smashes. Tennis rackets are designed for long-distance power while these tools focus on tactical placement and defensive maneuvers near the glass. The absence of strings means that you do not need to worry about tension loss or breakage during a match. Grip sizes are generally universal though players often add overgrips to customize the thickness of the handle. Choosing the right gear is a fundamental step for any club owner looking to stock a rental shop.

Structural materials and core foam

You see,

● Carbon fiber frames for maximum durability

● EVA foam density and rebound characteristics

● Fiberglass faces for beginner-friendly play

The internal foam determines how much effort you need to put into every shot to clear the net. High-density cores provide more power while soft foams offer better comfort for people with elbow injuries. You will find that professional players prefer stiff rackets that respond instantly to their technical inputs. This material science is a huge part of the industry that drives sales for club pro shops.

The aerodynamic hole pattern system

Think about it:

● Drag reduction during the swing phase

● Grip enhancement on the ball surface

● Weight distribution for balanced handling

Engineers carefully calculate the placement of the holes to ensure that the racket moves smoothly through the air. You might think these holes are just for decoration but they actually prevent the tool from feeling like a heavy paddle. The pattern also affects the “sweet spot” where the ball makes the most efficient contact with the face. Modern designs often use variable hole sizes to optimize the performance across the entire hitting area.

Safety straps and handle ergonomics

What’s the real story?

● Mandatory wrist straps for player safety

● Short handles for increased maneuverability

● Ergonomic grips to prevent blisters

Every racket must have a safety cord that you wrap around your wrist before entering the court. This prevents the heavy tool from flying out of your hand and hitting your partner or the glass walls. You will appreciate the extra security when you are swinging hard at a high lob near the net. Our about us page details how we source the best accessories to complement our court installations.

| Gear Aspect | Padel Racket | Tennis Racket |

|---|---|---|

| Surface | Solid with Holes | Strung Mesh |

| Length | Max 45.5 cm | Approx 68.5 cm |

| Weight | 350g – 380g | 280g – 330g |

| Core | Foam/Rubber | Hollow Frame |

Racket technology continues to evolve toward lighter and stronger materials that allow for even faster gameplay and better injury prevention.

Key Takeaway: Solid racket design prioritizes touch and control which makes the sport accessible to players without extensive tennis backgrounds.

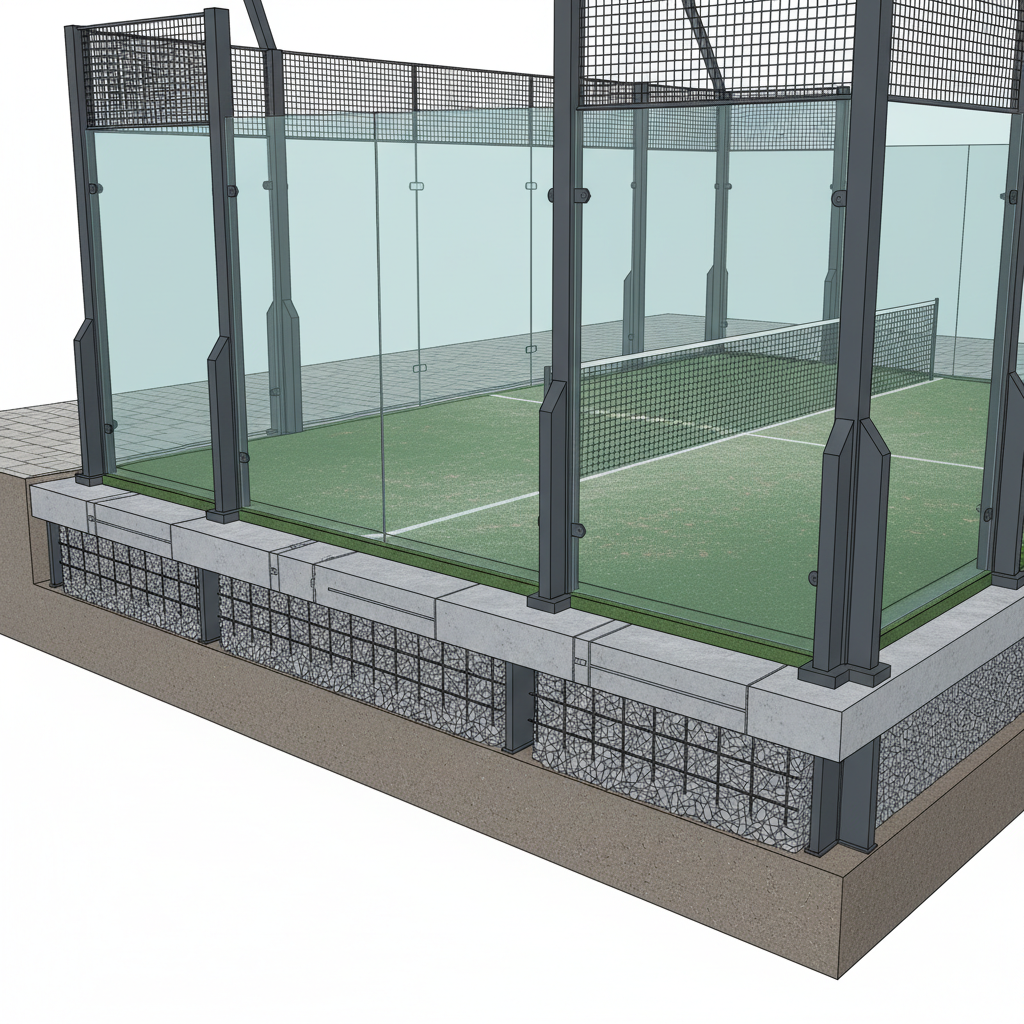

- What is padel court site preparation?

Padel site preparation involves creating a perfectly level and reinforced concrete foundation to support the heavy steel and glass structure. Developing what is padel facilities requires a deep understanding of soil stability to prevent ground shifting over the long term. You must excavate the topsoil and replace it with a compacted gravel base that facilitates proper drainage under the slab. Reinforced concrete with a thickness of at least fifteen centimeters provides the necessary strength to anchor the metal pillars. This foundation ensures that the court remains flat which is vital for a consistent ball bounce across the turf. Skipping these steps leads to cracked glass and uneven surfaces that will ruin the player experience.

Padel foundations must include integrated drainage channels if you are building an outdoor club in a rainy climate. You should install porous concrete or a slight slope that directs water toward the edges of the playing zone. This prevents the synthetic grass from becoming waterlogged which can cause mold and slippery conditions for the athletes. Electrical conduits for the lighting system should be buried within the foundation before the final pour of the concrete. You need to verify that all anchor points for the steel frame are precisely positioned according to the engineering drawings. Proper preparation reduces the risk of structural failure and extends the life of your investment by many years.

Soil testing and excavation work

But wait, there’s more,

● Removal of organic matter and loose soil

● Compaction of the sub-base material

● Assessment of the water table levels

The ground beneath your court must be stable enough to handle the weight of several tons of tempered glass. You will need to hire a contractor who understands the specific load requirements for sports facilities. Poor compaction leads to settling which can cause the entire steel frame to warp and twist. This initial work is the most important part of the entire construction process for any serious club.

Concrete slab and reinforcement steel

Ready for the good part?

● Steel mesh integration for tensile strength

● Precise leveling using laser guided tools

● Curing times for maximum slab hardness

The concrete needs time to reach its full strength before you begin the assembly of the metal structure. You should wait at least twenty-one days for the curing process to complete properly in most weather conditions. A smooth finish on the slab allows the synthetic turf to sit perfectly without any lumps or bumps. This high-quality base is the secret to a professional-grade facility that attracts elite players to your brand.

Drainage systems and moisture control

Here’s the deal,

● Porous asphalt options for fast drying

● Perimeter gutters to manage heavy rain

● Slope gradients that remain undetectable

Water is the enemy of any sports surface because it damages the glue and the turf fibers. You must ensure that your site can handle a sudden downpour without flooding the playing area for hours. Most modern builders prefer porous systems that allow the water to drain directly through the concrete slab. This keeps the courts playable even shortly after the rain stops which maximizes your potential booking hours.

| Prep Step | Material Used | Function |

|---|---|---|

| Sub-base | Crushed Stone | Ground Stability |

| Foundation | Reinforced Concrete | Structural Support |

| Drainage | Slotted PVC Pipes | Water Removal |

| Leveling | Laser Screed | Surface Accuracy |

A solid foundation prevents expensive repairs and ensures that your facility remains safe and attractive for your target market.

Key Takeaway: Professional site preparation is the only way to guarantee the long-term structural integrity and playability of a sports court.

- What is padel structure and frame quality?

Padel court structures consist of heavy-duty galvanized steel tubes that form the skeleton for the glass walls and mesh fencing. Assessing what is padel durability involves checking the thickness of the metal profiles which should be at least three millimeters. You will find that hot-dip galvanizing protects the steel from rust especially in humid coastal environments where salt air is present. The modular design allows for fast assembly on site without the need for complex welding or cutting. Every pillar must be securely bolted to the concrete foundation to resist high wind loads during stormy weather. High-quality powder coating adds a professional finish that matches your club’s specific branding and color scheme.

Padel frames use a combination of vertical posts and horizontal rails to create a rigid cage that can withstand player impacts. You should look for structural designs that hide the bolts and brackets for a cleaner and more modern aesthetic. Electro-welded mesh sections must be flush with the frame to prevent the ball from taking weird bounces during the game. The glass panels sit within these frames on rubber gaskets that prevent direct contact between the hard materials. This flexibility allows the structure to absorb the energy of a player running into the wall without breaking the glass. Investing in a robust frame reduces your maintenance costs and improves the overall safety of your facility.

Galvanization and corrosion protection

What’s the real story?

● Hot-dip galvanizing inside and out

● Zinc coating thickness for coastal sites

● Powder coating for aesthetic durability

Rust can destroy a metal structure in a few short years if the surface is not treated properly. You will appreciate the peace of mind that comes from a factory-treated frame that resists the elements. We use specialized ovens to bake the powder coating which creates a hard shell that resists scratches and fading. This process ensures that your courts look brand new even after several seasons of heavy use.

Modular assembly and engineering

You see,

● Precision cut components for perfect fit

● Simplified bolt-together system for speed

● Interchangeable parts for easy repair

A modular structure means you can set up a new court in just a few days with a small team. You will save money on labor costs because the pieces fit together like a giant construction set. This efficiency is why many club owners choose our factory-direct solutions for their large-scale projects. If a section ever gets damaged you can simply order a replacement part instead of replacing the whole frame.

Impact resistance and player safety

Think about it:

● Reinforced pillars for high-traffic zones

● Hidden hardware to prevent injury

● Flexible glass mounting systems

Players often crash into the walls while trying to reach a difficult ball near the back of the court. You need a structure that can handle these forces without shaking or making loud noises that distract others. The integration of rubber dampers helps to quiet the impact and protects the integrity of the glass panels. Safety is the most valuable asset you can offer to your members and it starts with the frame.

| Component | Material | Specification |

|---|---|---|

| Main Pillars | Carbon Steel | 100x80x3mm Tube |

| Mesh Panels | Welded Wire | 50x50x4mm Grid |

| Fasteners | Stainless Steel | Grade 304 Bolts |

| Finish | Powder Coat | UV Resistant |

High-grade steel construction provides the necessary rigidity and longevity required for a commercial sports facility to thrive over many years.

Key Takeaway: Investing in a hot-dip galvanized frame prevents structural rust and ensures the safety of your clients for decades.

- What is padel turf and grass selection?

Padel turf is a specialized synthetic grass designed to hold a layer of fine silica sand that provides grip and cushioning. Selecting what is padel surfacing requires choosing between monofilament and fibrillated fibers based on your expected traffic levels. You will notice that monofilament grass stands upright better and offers a more professional appearance for high-end clubs. The sand must be kiln-dried and free from impurities to ensure it spreads evenly across the entire court surface. Proper sand levels allow players to slide safely which reduces the risk of knee and ankle injuries during play. Blue has become the industry standard color because it provides the best contrast for the ball on television.

Padel grass density is measured by the number of stitches per square meter which directly impacts the durability of the court. You should aim for a high stitch rate to prevent the fibers from flattening out after only a few months of use. Fibrillated turf is often cheaper and easier to install because it holds the sand more securely in place. However many professional players prefer the consistent bounce provided by high-density monofilament systems. The backing of the turf must be porous to allow for drainage while remaining strong enough to resist the tearing forces of pivoting feet. Regular maintenance involving brushing the sand is necessary to keep the playing conditions perfect for every match.

Monofilament vs fibrillated fibers

Ready for the good part?

● Monofilament for resilience and look

● Fibrillated for sand retention and value

● Texturized fibers for top-tier performance

Each fiber type offers different benefits depending on your budget and the climate where you are building. You will find that texturized grass requires less sand and offers a very consistent feel for competitive matches. This modern innovation is becoming the go-to choice for new indoor clubs that want a premium aesthetic. Our padel grass options are designed to meet all European quality standards for sports surfaces.

Silica sand infill requirements

But wait, there’s more,

● Round-grain sand to prevent abrasion

● Kiln-dried to ensure easy distribution

● Optimal weight per square meter

The sand acts as the ballast that keeps the turf in place and provides the necessary friction for the game. You should use roughly three tons of sand for a standard court to achieve the correct depth. Using the wrong type of sand can cause the turf fibers to wear out prematurely and creates a dusty environment. Clear or white sand is preferred