Sports facility owners often face a frustrating ceiling on revenue because they simply lack the space to expand. You want to increase booking capacity and member engagement, but acquiring new land is expensive and time-consuming. Padel court construction offers a high-yield solution by transforming underutilized areas into high-density profit centers. As an experienced manufacturer, we provide the industrial expertise and factory-direct precision needed to build durable, professional-grade courts that maximize your return on investment.

Table of Contents

- 1. Why is padel court construction a smart investment?

- 2. How does design impact padel court construction?

- 3. What are dimensions for padel court construction?

- 4. How do walls affect padel court construction?

- 5. Why is fencing vital in padel court construction?

- 6. How to pick turf for padel court construction?

- 7. How does lighting aid padel court construction?

- 8. How does the padel court construction process work?

- 9. How much does padel court construction cost?

- 10. How do roofs enhance padel court construction?

- Conclusion

- Frequently Asked Questions

1. Why is padel court construction a smart investment?

● Understanding the global padel boom

● High ROI and low maintenance costs

● Optimizing unused club space

Investing in padel court construction allows club owners to capitalize on the fastest-growing racquet sport globally. Demand for courts currently outstrips supply in many regions, creating a massive opportunity for early adopters. Here’s the deal: a standard tennis court covers about 650 square meters, whereas a single padel court requires roughly 200 square meters. You can fit three padel courts in the space of one tennis court. Since each padel match involves four players, you triple your simultaneous player capacity instantly. This density transforms low-yield real estate into a buzzing hub of activity.

Financial returns on these projects are compelling. Initial capital expenditure remains relatively low compared to building large gymnasiums or swimming pools. Operational costs stay minimal because modern materials like galvanized steel and artificial turf withstand weather effectively. Most facilities report recovering their initial investment within two years. You might be wondering about the long-term viability. The social nature of the sport drives high player retention. Friends book weekly slots, ensuring consistent revenue streams regardless of seasonal trends.

| Metric | Tennis Court | Padel Court | Efficiency Gain |

|---|---|---|---|

| Footprint | ~650 m² | ~200 m² | 3x Density |

| Players | 2-4 | 4 | Higher Capacity |

| Hourly Yield | $20 avg | $40 avg | Double Revenue |

| Build Time | 4-6 Weeks | 2-3 Weeks | Faster Launch |

2. How does design impact padel court construction?

● Essential layout and orientation factors

● Indoor vs. outdoor: which is better?

Thoughtful design in padel court construction prevents costly operational headaches down the road. Orientation is critical for player comfort; courts should align North-South to minimize sun glare during peak morning and evening hours. Site analysis must account for local wind loads, especially for outdoor installations in coastal areas. But here’s the kicker: failing to account for proper drainage slopes can ruin the playing surface within months. A slight gradient of 0.5% to 1% ensures water flows away from the center, preventing puddles that cancel matches.

Indoor facilities offer the distinct advantage of year-round playability. They guarantee revenue during rainy seasons when outdoor clubs sit empty. However, they require significant ceiling clearance and climate control systems. Outdoor courts generally cost less to build but remain at the mercy of the weather. Permits are another hurdle you cannot ignore. Local zoning laws dictate setback distances, noise restrictions, and maximum fence heights. Engaging with municipal authorities early avoids construction delays later. Accessibility for maintenance equipment must also be planned into the layout.

3. What are dimensions for padel court construction?

● Standard court measurements (20x10m)

● Understanding service lines and net height

● Ceiling height requirements for indoor clubs

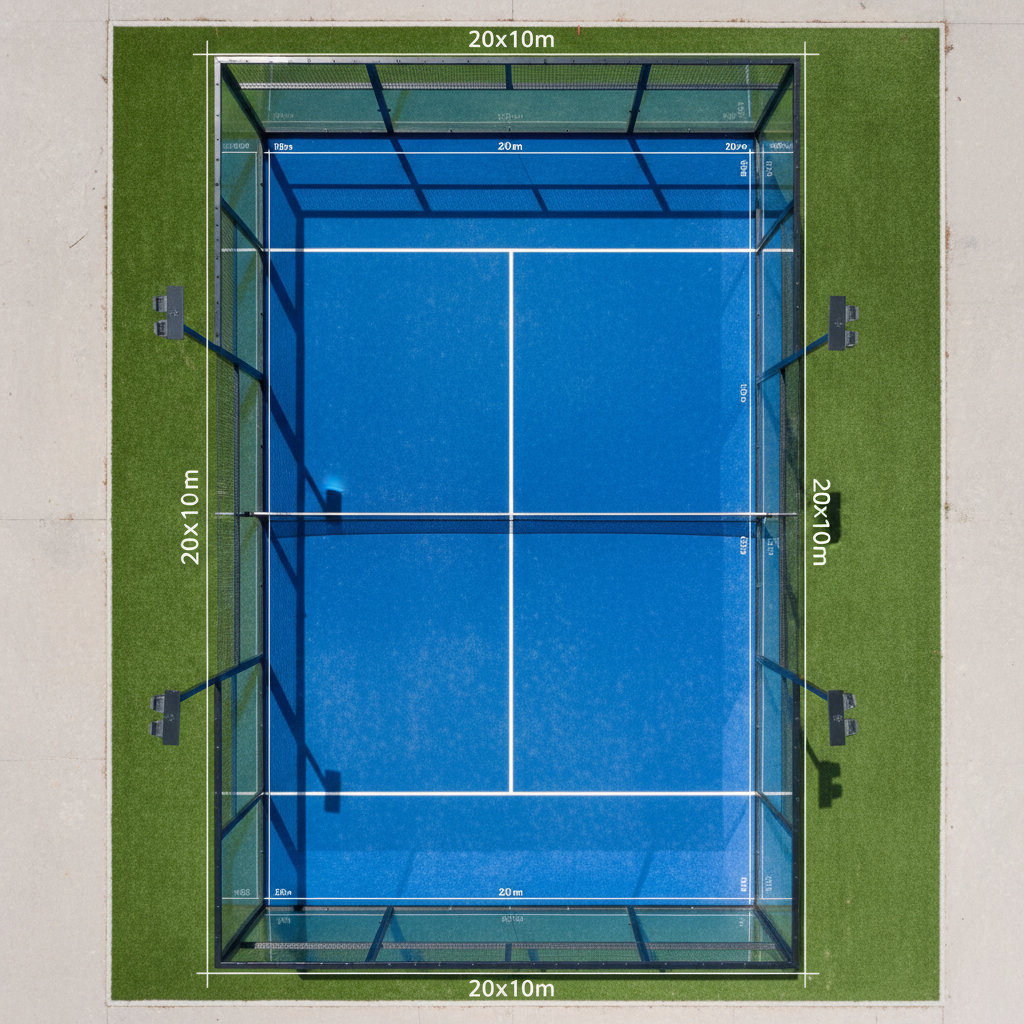

Accuracy in measurements is non-negotiable for padel court construction if you intend to host official tournaments. A standard single court measures exactly twenty meters long by ten meters wide. Inner tolerances allow for minimal deviation, typically less than a few millimeters across the entire length. What’s the real story? Many builders overlook the “out-of-court” play zone. Regulations mandate at least two meters of unobstructed clearance outside the gates for players to run out and retrieve balls. This zone requires safety flooring matching the interior turf.

Service lines sit precisely 6.95 meters from the net, dividing the backcourt into service boxes. The central net stands 88 centimeters high at the center, rising to 92 centimeters at the posts. Indoor facilities face additional vertical constraints. A minimum clear ceiling height of six meters enables safe lobs, though seven meters or more is preferred for competitive play. Lighting fixtures must hang outside this clear volume to avoid interference. Adhering strictly to these dimensions prevents disputes during competitive matches and ensures FIP certification.

| Component | Measurement (Metric) | Tolerance |

|---|---|---|

| Length | 20.00 meters | ±0.5% |

| Width | 10.00 meters | ±0.5% |

| Net Height (Center) | 0.88 meters | ±0.005m |

| Service Line | 6.95 meters | ±0.005m |

| Out-of-court Zone | 2.00 meters wide | Min. required |

4. How do walls affect padel court construction?

● Glass vs. solid wall options

● Benefits of panoramic court designs

● Safety standards for tempered glass

Walls act as active playing surfaces in padel court construction, demanding exceptional rebound consistency. While concrete offers durability, modern clubs overwhelmingly prefer 12mm tempered safety glass for its sleek aesthetics and spectator visibility. This material resists high-impact collisions without shattering into dangerous shards. Thick panels ensure consistent ball rebound, which is critical for professional gameplay. Ready for the good part? Panoramic designs eliminate rear corner pillars entirely, offering unobstructed views that television broadcasters and spectators love.

These panoramic systems use thicker glass, often 12mm, and specialized anchoring for structural rigidity. Joints between panels must be seamless to prevent ball deviation during play. Neoprene gaskets separate glass from metal, absorbing vibration and reducing noise pollution. Countersunk holes prevent screws from protruding into the playing area, removing a common injury risk. Regular inspections should check for chips or stress fractures. Proper wall installation transforms a simple cage into a premium stadium experience.

5. Why is fencing vital in padel court construction?

● Zinc vs. plasticized mesh durability

● Ensuring player safety and ball containment

● Anti-corrosion materials for longevity

Fencing encloses the court while allowing air flow and visibility, making it a critical safety component in padel court construction. The mesh sections must withstand constant impact from bodies and racquets without deforming. We utilize a high-strength modular steel structure that integrates electro-welded wire mesh seamlessly with the posts. This frame undergoes hot-dip galvanization to prevent rust formation, even in humid coastal environments. Powder coating adds a second protective layer, allowing customization with brand colors.

This is where it gets interesting… mesh openings must be small enough to prevent balls from getting stuck but large enough to see through. “Anti-injury” manufacturing processes remove sharp edges where players might catch fingers or clothing. Rigid panels prevent the “trampoline effect,” which could alter ball trajectory unpredictably. Structural posts require sturdy anchoring plates bolted into the concrete foundation. High-quality fasteners resist loosening caused by vibration. A robust fence system ensures matches proceed safely without equipment failure interruptions.

| Feature | Electro-Welded Mesh | Chain Link |

|---|---|---|

| Rigidity | High (Consistent bounce) | Low (Trampoline effect) |

| Durability | Excellent | Moderate |

| Safety | Anti-injury edges | Risk of snagging |

| Aesthetics | Professional/Clean | Basic/Industrial |

6. How to pick turf for padel court construction?

● Advantages of synthetic grass surfaces

● Ensuring consistent ball bounce

● Preventing injuries with proper grip

Flooring directly influences game speed and player comfort in padel court construction. Synthetic turf remains the industry standard, balancing durability with performance. For facilities expecting heavy traffic, we recommend resilient fibrillated turf because its web-like structure holds sand infill more effectively. This creates a stable surface that resists shifting under fast footwork. Monofilament turf, while offering a cleaner look, requires more frequent brushing to maintain optimal sand distribution.

Grip levels determine injury risk. Too much traction causes knee strain; too little leads to dangerous slipping. Manufacturers texture fibers to optimize friction coefficients. Here is why this matters: the sand infill acts as a cushion, protecting the fibers from crushing and allowing players to slide in a controlled manner. Drainage holes perforated into the backing allow rainwater to escape quickly, essential for outdoor courts. Regular maintenance involves redistribution of silica sand to ensure consistent bounce characteristics across the entire court.

7. How does lighting aid padel court construction?

● Maximizing visibility with LED systems

● Avoiding player dazzle during matches

● IP66 waterproof ratings for outdoor use

Proper illumination extends playing hours well into the night, maximizing revenue for padel court construction projects. Shadows or dark spots frustrate players and cause misjudgments during fast rallies. LED technology delivers high brightness with low energy consumption. We install waterproof LED floodlights rated IP66 for all outdoor installations to ensure rain and dust do not compromise the electronics. Fixtures typically mount six meters high, angled specifically to light the court without blinding players during overhead smashes.

Uniformity becomes as important as intensity. A lux level of 200 suffices for training, but tournaments require 500 lux or more. Think about it: players looking up for a lob should not be blinded by the lights. Asymmetric lenses project light forward onto the court, reducing light spill into neighboring properties. Color temperature around 5000K mimics daylight, keeping players alert and focused. Wiring runs inside structural posts, maintaining a clean aesthetic. Smart controls allow dimming when courts sit empty, saving electricity.

8. How does the padel court construction process work?

● Site inspection and concrete slab prep

● Structural assembly and leveling

● Installation of turf and glass

Construction follows a precise sequence ensuring structural integrity for every padel court construction project. It begins with ground preparation. Excavation removes unstable soil, replaced by compacted gravel to prevent settling. A reinforced concrete perimeter beam supports the steel frame’s weight. The slab typically uses porous concrete or a sloped design allowing water drainage. This eliminates puddles instantly after rain, preserving the playing surface.

Once the foundation cures, assembly crews erect the steel skeleton. Laser leveling ensures posts stand perfectly vertical. Let’s face it, even a millimeter of lean can make glass installation impossible. Glass panels arrive in crates and are lifted carefully into position using suction cups. Installers tighten bolts systematically, checking alignment constantly. Turf rolls out last, cut precisely to fit corners. Sand spreading machines distribute infill, which is then brushed deep into the fibers. Final inspections verify net tension and lighting function.

| Step | Activity | Duration (Approx) |

|---|---|---|

| 1 | Site Clearing & Excavation | 1-2 Days |

| 2 | Concrete Beam/Slab Pour | 2-3 Days |

| 3 | Curing Time | 2-3 Weeks |

| 4 | Steel Structure Assembly | 2 Days |

| 5 | Glass Installation | 1 Day |

| 6 | Turf Laying & Infill | 1-2 Days |

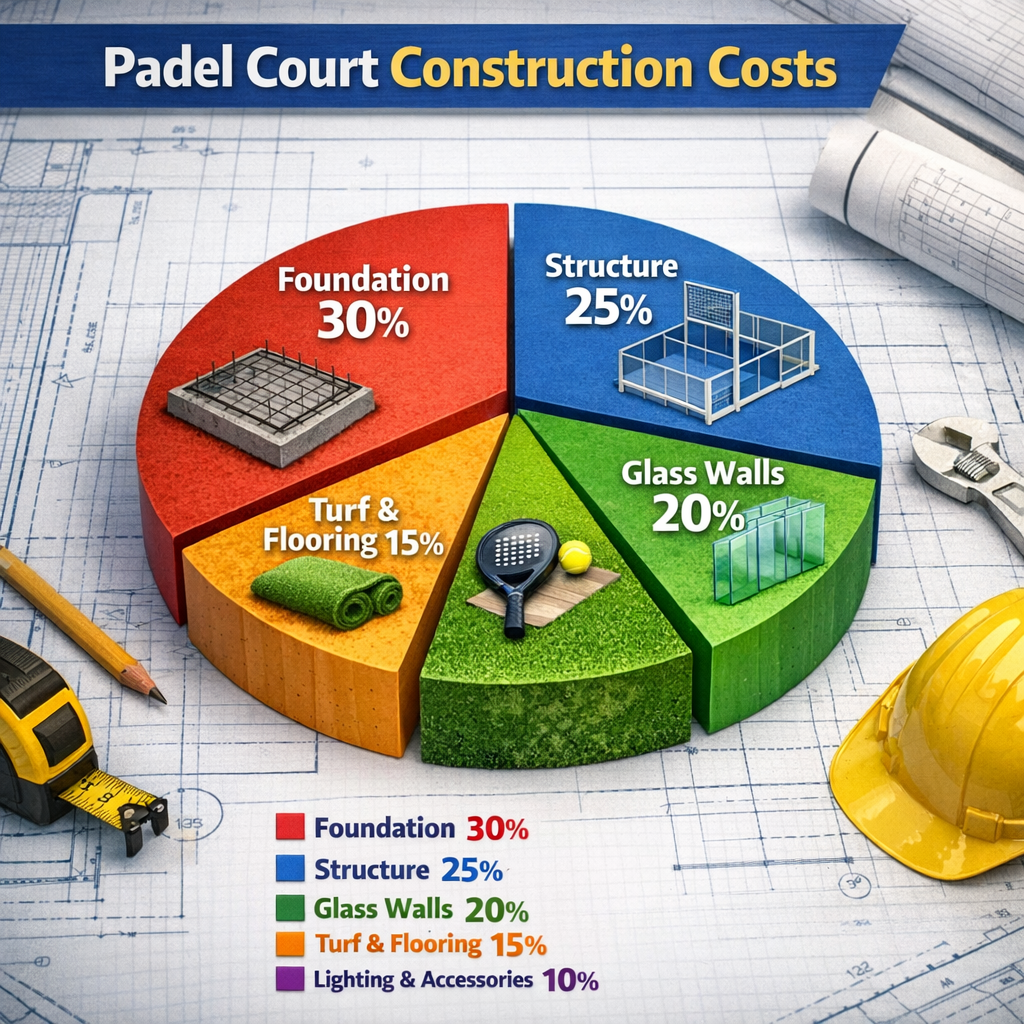

9. How much does padel court construction cost?

● Factors influencing the final budget

● Hidden costs you need to anticipate

● Calculating the return on investment

Pricing varies based on specifications and location, but understanding the components of padel court construction helps in budgeting. A standard court costs less than a panoramic model due to thinner glass and simpler steelwork. Importing factory-direct saves money on materials but requires handling customs clearance and logistics. Foundation work often represents the largest variable expense. Poor soil conditions require deeper excavation or specialized reinforcement, which can inflate the budget unexpectedly.

Electrical connections usually fall outside the manufacturer’s quote. Investors must budget for trenching and cabling from the main grid to the court. Accessories like electronic scoreboards or benches add small increments. The best part? Despite these costs, the business model remains robust. High hourly rental rates offset initial outlays quickly. Volume discounts apply when purchasing multiple units, improving margins. Clear communication with suppliers prevents surprise fees during the build. Smart budgeting focuses on quality components that minimize long-term replacement costs.

10. How do roofs enhance padel court construction?

● Ensuring year-round playability

● Protection from rain and intense sun

● Integrated roofing system options

Weather dependency creates the biggest risk for outdoor clubs, but roofing solves this challenge in padel court construction. Rain cancels matches, and intense midday sun discourages play, leading to lost revenue. Installing a roof mitigates these issues entirely. Covered courts command higher rental fees because they guarantee game time regardless of the forecast. Structural covers can be integrated directly onto the court columns or stand as separate independent canopies covering multiple courts.

Ventilation remains crucial under roofs. Open sides allow breezes to cool players, preventing the “greenhouse effect” common in fully enclosed tents. Height clearance must accommodate high lobs without obstruction; typically, the roof peak sits well above seven meters. Polycarbonate sheets allow natural light penetration while blocking harmful UV rays. Here’s the bottom line: while roofing adds to the upfront investment, it stabilizes revenue streams significantly. Players prefer reliability, making roofed venues the default choice for leagues and tournaments.

Conclusion

Building a padel court offers a clear path toward revitalizing sports facilities and generating significant revenue. We have explored how design, materials, and precise padel court construction techniques determine long-term success. Every component, from the hot-dip galvanized steel frame to the tempered safety glass, plays a vital role in player safety and court longevity. Ready to take the next step? You can start your project with confidence by choosing a partner who understands these details intimately. Contact us today to discuss your specific requirements and receive a customized quote. Padel continues growing globally; ensuring your facility meets professional standards places you ahead of the competition.

Frequently Asked Questions

Q1: What is the minimum space required?

A single padel court requires an area of at least 20 meters by 10 meters. However, we recommend allowing extra space for circulation and safety runs. A footprint of 22×12 meters ensures players can exit the court safely during intense points.

Q2: Can I build on an existing tennis court?

Yes, existing tennis courts provide excellent foundations for padel conversion. One standard tennis court can typically accommodate up to three padel courts. The existing concrete or asphalt base usually requires only minor leveling or drainage modifications before installation.

Q3: How long does installation take?

Once the concrete foundation is ready and cured, the actual assembly of the court structure takes very little time. A professional team typically completes the steel erection, glass installation, and turf laying for one court in approximately 3 to 5 days.

Q4: Is planning permission required?

Most jurisdictions classify padel courts as permanent structures requiring building permits. Regulations vary by municipality regarding height, noise, and setbacks. We strongly advise checking with local planning authorities before commencing any ground work.

Q5: What is the lifespan of a padel court?

High-quality components significantly extend the facility’s life. The galvanized steel structure can last over 20 years without corrosion. Artificial turf typically requires replacement every 5 to 7 years depending on usage intensity and maintenance quality.