Facilities crumble when developers neglect the most critical touchpoint of the game. You pour capital into steel and glass, yet a substandard floor will rapidly deteriorate, causing player injuries and draining your maintenance budget within months. Here is the deal: The solution lies in selecting a padel court surface engineered for durability and biomechanical safety. We deliver the definitive expertise you need to construct a high-performance court that maximizes player retention and return on investment.

1. What Are the Best Padel Court Surface Options?

The premier options for a padel court surface are artificial turf, porous concrete, and synthetic resin, with turf being the overwhelming commercial favorite. While concrete serves well for durability and resins offer speed, artificial turf provides the optimal balance of grip, slide, and shock absorption required for modern competitive play.

Artificial Turf Varieties

Synthetic grass dominates the market because it mimics natural play mechanics while enduring heavy traffic.

- Fibrillated Fibers: These mesh-like strands split at the top to anchor the sand infill securely, creating a stable playing field ideal for heavy use.

- Monofilament Fibers: Individual upright blades offer superior aesthetics and durability, providing a slightly slower game preferred by advanced tacticians.

- Texturized Turf: Crimped fibers encapsulate the sand, requiring less maintenance and offering a consistent, premium ball bounce.

Hard Court Alternatives

Rigid materials still have a niche application in specific environments.

- Porous Concrete: Excellent for rainy climates as it allows water to drain instantly, though it is harder on player joints.

- Acrylic Resin: Often applied over concrete for indoor arenas to increase ball speed, popular in multi-sport complexes.

- Asphalt: A budget-friendly base option, though it retains significant heat and offers zero shock absorption.

Surface Performance Comparison

Selecting the right material requires balancing speed, maintenance, and comfort.

| Feature | Artificial Turf | Porous Concrete | Acrylic Resin |

|---|---|---|---|

| Player Comfort | High (Cushioned) | Low (Hard) | Medium (Firm) |

| Ball Speed | Medium/Slow | Fast | Very Fast |

| Maintenance | Regular Brushing | Pressure Washing | Surface Cleaning |

| Est. Lifespan | 5-7 Years | 20+ Years | 8-10 Years |

2. What Is the Total Surface Area of Padel Courts?

A standard padel court surface covers exactly 200 square meters, measuring 20 meters in length and 10 meters in width. This compact footprint allows club owners to maximize revenue per square meter, fitting significantly more active players into a given space compared to tennis.

Official Dimensional Standards

Federation regulations dictate precise measurements for competitive compliance.

- Play Area: The rectangle must measure exactly 20m x 10m with a tolerance of only 0.5%.

- Service Lines: Positioned 6.95 meters from the net, extending across the court.

- Center Line: Divides the service box into two equal 5m x 6.95m rectangles.

Efficiency Against Tennis

Real estate optimization is a key driver for padel’s explosive B2B growth.

- Footprint: A single tennis court (approx. 600+ sqm with run-off) consumes the space of three padel courts.

- Density: Padel allows for 12 players to be active in the same area where tennis accommodates only 2 to 4.

- Revenue: Tripling the court density on the same land dramatically increases booking potential.

Perimeter Requirements

Safety zones are just as important as the standard commercial-grade padel court interior.

- Run-off Zone: A minimum of 2 meters is required outside the doors for out-of-court play.

- Vertical Clearance: Indoor facilities must maintain a clear height of at least 6 meters, though 8 meters is recommended for lob shots.

3. How Do You Choose the Right Padel Court Flooring?

Selecting the ideal padel court surface hinges on your facility’s specific business model, local climate, and customer demographics. You might be wondering, does one solution fit all? No, the decision must align with whether you operate a high-performance indoor club or a rugged outdoor municipal center.

Assessing Location and Climate

The environment dictates the material’s necessary resistance properties.

- Indoor Clubs: Prioritize ball response and aesthetics; UV resistance is less critical, allowing for a wider range of turf colors.

- Outdoor Facilities: Drainage capacity is paramount; porous concrete or turf with superior permeability prevents rain delays.

- Temperature: In hot regions, avoid black or dark blue surfaces that absorb excessive heat.

Player Experience Levels

Your clientele determines the necessary friction and speed.

- Beginners: Slower surfaces like fibrillated turf help sustain rallies and increase enjoyment.

- Professionals: Faster, texturized surfaces reward power and precision, suitable for tournament venues.

- Elderly Players: softer, sand-filled systems reduce impact on knees and hips, prolonging their playing years.

Strategic Selection Matrix

Align your business goals with the surface attributes.

| Facility Type | Recommended Surface | Key Benefit |

|---|---|---|

| Indoor Commercial Club | Monofilament Turf | Aesthetics & Durability |

| Outdoor Public Court | Fibrillated Turf | Sand Stability & Grip |

| High-End Resort | Texturized Turf | Premium Look & Low Maintenance |

| Rainy Climate Outdoor | Porous Concrete Base | Immediate Drainage |

4. Why Is Artificial Turf the Top Padel Court Surface?

Artificial turf stands as the undisputed champion of padel court surface materials because it offers a customizable slide-to-grip ratio that hard courts simply cannot match. It functions as a suspension system for the athlete, reducing fatigue while ensuring a consistent, predictable ball bounce.

Fiber Technology and Performance

The engineering behind the plastic blade defines the play.

- High-Density Fibrillated Turf: This high-density fibrillated turf anchors sand effectively, making it the most stable and forgiving surface for general play.

- Elastic Memory: Quality monofilament fibers return to an upright position after being stepped on, ensuring the ball doesn’t skid unpredictably.

- Wear Resistance: Polyethylene fibers are designed to withstand the twisting friction of padel shoes without snapping.

The Critical Role of Sand Infill

Sand acts as the structural backbone of the turf system.

- Stability: The weight of the silica sand keeps the turf carpet flat and immobile without heavy gluing.

- Movement: It creates a unique surface where players can slide safely into shots, preventing joint locking.

- Protection: The sand layer protects the fiber roots from direct stud impact and UV exposure.

Turf System Analysis

Understanding the components helps justify the investment.

- Pile Height: Typically 10mm to 12mm for padel; shorter than football turf to ensure a true bounce.

- Stitch Rate: Higher density (stitches per sqm) means a more robust surface and better ball behavior.

- Backing: A double-layer backing with drainage holes ensures durability and water permeability.

5. How Do You Prepare the Base for a New Surface?

A padel court surface is only as reliable as the sub-base beneath it; even the most expensive turf will fail if the foundation shifts or cracks. Ready for the good part? Investing in a reinforced perimeter and a perfectly leveled slab guarantees your court remains playable for decades.

Excavation and Ground Stabilization

The earth must be prepared to support tons of concrete and steel.

- Excavation: Remove 20-30cm of topsoil to reach a stable strata.

- Compaction: Use heavy industrial rollers to compact the soil and prevent future settling or sinkholes.

- Gravel Layer: Install a bed of crushed stone to facilitate drainage and provide a solid working platform.

Concrete Slab vs. Ring Beam

Structural integrity is non-negotiable for safety.

- Perimeter Ring Beam: A reinforced concrete frame supports the galvanized steel modular structure, essential for anchoring the heavy glass walls.

- Full Slab: Pouring a 15cm reinforced concrete slab across the entire court prevents weed growth and ensures a perfectly flat playing surface.

- Leveling: The surface must be laser-leveled with a tolerance of less than 3mm over 3 meters.

Drainage Systems for Outdoor Courts

Water management prevents damage and downtime.

| Component | Function | Importance |

|---|---|---|

| Surface Slope | 0.5% – 1% gradient | Guarantees runoff |

| Porous Asphalt | Vertical drainage | prevents puddles |

| Perimeter Drains | Channel collection | Protects surroundings |

6. How Do You Build the Padel Court Surface Step-by-Step?

Constructing the padel court surface is a precision craft that requires adherence to strict protocols to avoid wrinkles, seams, and dead spots. A rushed installation often results in a surface that plays unevenly and degrades prematurely.

Turf Layout and Acclimatization

The carpet needs time to relax before fixation.

- Unrolling: Roll out the turf sections and let them sit for 24 hours to remove manufacturing creases.

- Cutting: Trim the edges precisely to fit the 20x10m area, ensuring a tight fit against the perimeter walls.

- Seaming: Use specialized joining tape and high-strength polyurethane adhesive to bond the rolls together seamlessly.

Integrating the Game Lines

White lines must be permanently integrated, not painted.

- Tufting: Some premium courts come with lines pre-tufted to avoid seams.

- Cutting In: Installers manually cut 5cm strips of white turf and glue them into the green or blue surface.

- Precision: Measurements must be exact to federation standards to avoid disputes during play.

Sand Distribution and Brushing

This final step defines the court’s playability.

- Spreading: Apply dry, rounded silica sand evenly across the court using a drop spreader.

- Quantity: Approximately 3-4 tons of sand per court, depending on the pile height (usually 10-15kg/sqm).

- Power Brushing: Mechanically brush the sand deep into the fibers to stand them up and create a uniform cushion.

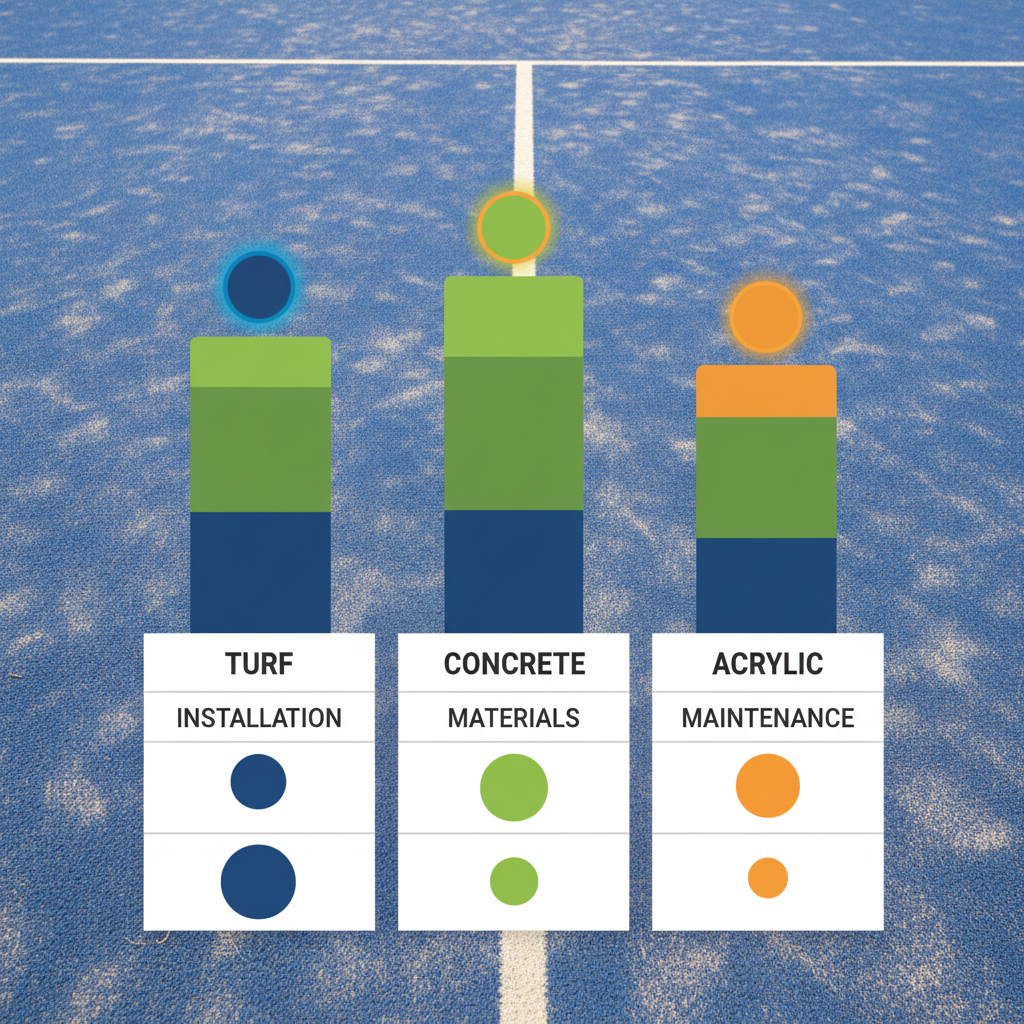

7. How Does the Cost Vary Between Surface Materials?

The price of a padel court surface fluctuates based on material technology, logistical requirements, and labor expertise. While the surface represents a fraction of the total project cost, skimping here leads to the highest long-term expenses.

Material Cost Factors

Different technologies command different market prices.

- Entry-Level: Fibrillated turf is the most budget-friendly option, offering good performance for the price.

- Mid-Range: Standard monofilament turf offers better aesthetics and durability, costing slightly more.

- Premium: Texturized or “curly” turf commands a 20-30% premium but significantly reduces maintenance labor.

Installation and Labor

Skilled installation is an investment in longevity.

- Specialist Teams: Proper seaming and sanding require experienced technicians, not general laborers.

- Equipment: The cost includes the rental or transport of sanding machines and power brushes.

- Logistics: Shipping heavy rolls of turf and tons of sand can add substantially to the budget in remote locations.

Long-Term Value Analysis

Cheaper surfaces often cost more over a decade.

| Cost Category | Fibrillated Turf | Texturized Turf | Impact |

|---|---|---|---|

| Initial CapEx | Low | High | Upfront Investment |

| Sand Refill | Frequent | Low | Ongoing Maintenance |

| Replacement | Every 4-5 Years | Every 6-8 Years | Lifecycle Cost |

| Resale Value | Standard | Premium | Asset Valuation |

8. How Does the Surface Impact Player Safety?

A premium padel court surface acts as the primary safety equipment for athletes, mitigating impact forces and preventing dangerous falls. The interaction between the shoe, the sand, and the fiber determines whether a player slides safely or sustains an injury.

Shock Absorption and Joint Health

Hard surfaces transmit shock directly to the skeleton; turf dissipates it.

- Cushioning: The combination of sand infill and polymer fibers absorbs impact energy, protecting knees and ankles.

- Fatigue: Softer surfaces reduce muscle fatigue, allowing players to train longer and recover faster.

- Hard Courts: Concrete or asphalt significantly increases the risk of stress fractures and chronic joint pain.

Traction and Sliding Dynamics

The “slide” is a fundamental padel movement that requires precise friction.

- Locking: Too much grip (clean turf) causes shoes to stick, leading to twisted ankles and ligament damage.

- Slipping: Too much sand on top creates a skating rink effect, causing dangerous falls.

- Balance: Regular maintenance ensures the sand level provides the perfect coefficient of friction.

Interaction with the Enclosure

The transition from floor to wall must be seamless.

- Flush Edges: There must be zero gaps between the turf and the 12mm tempered safety glass to prevent erratic ball bounces.

- Trip Hazards: Any lifting seams or edges near the entrance gates pose a severe tripping risk.

- Consistency: A uniform surface ensures the ball behaves predictably when rebounding off the walls.

9. How Do Weather Conditions Affect Outdoor Surfaces?

Outdoor installations expose the padel court surface to harsh elements, making UV stability and thermal resistance critical factors. What is the real story? Water and sun are the primary enemies of your investment, and neglecting them leads to rapid failure.

UV Radiation and Degradation

The sun attacks the molecular structure of plastic fibers.

- Brittleness: UV exposure causes cheap fibers to become brittle and snap off, creating a bald court.

- Fading: High-quality turf includes UV stabilizers to maintain vibrant color for years.

- Warranty: Always demand a manufacturer’s warranty that specifically covers UV degradation for your latitude.

Thermal Expansion and Contraction

Materials expand in heat and shrink in cold, stressing the system.

- Wrinkling: Extreme heat can cause the turf carpet to expand and bubble if not properly glued or tensioned.

- Cracking: Concrete bases must have expansion joints to prevent thermal cracking during freeze-thaw cycles.

- Cooling: Watering the court lightly before play can significantly reduce the surface temperature in summer.

Rain and Drainage Efficiency

Standing water stops revenue and damages the foundation.

| Weather Issue | Solution | Benefit |

|---|---|---|

| Heavy Rain | Porous Base | Instant Playability |

| Moss/Algae | Chemical Treatment | Prevents Slipping |

| Freeze/Thaw | High-Grade Concrete | Prevents Cracking |

10. What Is the Lifespan of a Professional Surface?

Every padel court surface has a finite lifecycle, typically ranging from 5 to 7 years depending on usage intensity and maintenance rigor. Recognizing the signs of wear allows you to plan for resurfacing before safety is compromised.

Durability Metrics

Lifespan varies significantly by environment.

- Indoor Courts: Typically last 5 to 7 years as they are protected from UV and rain.

- Outdoor Courts: Usually require replacement every 4 to 6 years due to weather exposure.

- High Usage: Clubs with 8+ hours of daily play will see faster fiber degradation.

Signs You Need Replacement

Know when the surface is dead to prevent injury.

- Matting: Fibers are permanently flattened and will not stand up even after power brushing.

- Compaction: The sand infill has hardened into a concrete-like layer that cannot be de-compacted.

- Worn Spots: The backing material becomes visible in high-traffic areas, particularly near the service line and net.

Surface Lifespan Summary

Planning your sinking fund relies on accurate projections.

| Surface Type | Est. Lifespan | Main Advantage | Main Drawback |

|---|---|---|---|

| Fibrillated Turf | 4-5 Years | Sand Stability | Wears Faster |

| Monofilament Turf | 5-7 Years | Aesthetics | Sand Moves More |

| Texturized Turf | 6-8 Years | Low Maintenance | Higher Cost |

| Porous Concrete | 20+ Years | Structure | Hard on Joints |

Conclusion

The foundation of a successful club is quite literally the ground it stands on. Choosing the right padel court surface is a strategic business decision that directly impacts player safety, satisfaction, and your facility’s long-term profitability. From the precision engineering of the sub-base to the selection of UV-stabilized turf, every layer plays a vital role. Here is the kicker: You do not have to navigate these technical complexities alone. We provide end-to-end manufacturing and installation support to ensure your courts meet the highest international standards. For expert guidance and a tailored solution, contact us today and let us help you build a world-class facility.

FAQ

Q1: Can I install a padel court surface directly onto dirt or grass?

No, a padel court requires a rigid, perfectly level foundation, typically a reinforced concrete slab or porous asphalt. Installing directly on dirt will lead to sinking, uneven ball bounce, and structural failure of the glass walls.

Q2: What is the best padel court surface for a commercial club?

Artificial turf, specifically monofilament or texturized varieties, is the industry standard. It balances durability for high traffic with the necessary shock absorption and slide that players expect from a professional facility.

Q3: How do I know if my padel surface needs replacing?

You will notice that the fibers are permanently flattened and won’t stand up after brushing, or the sand has compacted into a hard, slippery layer. If the backing material is visible in high-wear areas, replacement is overdue.

Q4: Can I use a tennis court surface for padel?

While physically possible, hard tennis surfaces are not recommended for padel. They lack the necessary slide and cushioning, increasing the risk of joint impact injuries and altering the game’s intended pace.

Q5: How much maintenance does a padel court really need?

Regular maintenance is essential. You should brush the court every 2-3 weeks to redistribute sand and keep fibers upright. Additionally, you will need to add fresh sand once or twice a year to replace what is lost during play.