For years, padel facility operators and professional players have faced a silent drain on their performance and profitability. The problem? The use of generic “court shoes” that were never designed for the unique high-friction, high-rotation environment of a padel court. Players suffer from avoidable ankle inversions, premature fatigue, and joint wear, while club owners see a direct correlation between player discomfort and declining court bookings. It’s a systemic inefficiency that hampers the growth of the sport.

Agitating this issue further is the evolution of court technology. Modern synthetic turfs and panoramic enclosures demand more from footwear than ever before. If the footwear doesn’t keep pace with the infrastructure, the player experience collapses. Without specialized equipment, even the most expensive court becomes a liability for injury rather than a theater for elite play.

The solution lies in the precision engineering of wilson padel shoes. By integrating biomechanical research with advanced material science, these shoes are built from the ground up to handle the specific torque and impact of the padel game. This article serves as a comprehensive technical guide for B2B stakeholders, facility managers, and professional athletes on the construction, selection, and performance optimization of this specialized equipment.

wilson padel shoes: What defines the engineering of these high-performance tools?

The development of wilson padel shoes begins with a fundamental departure from traditional tennis footwear architecture. While tennis shoes are designed for the sliding dynamics of clay or the linear sprints of hard courts, padel requires a constant state of “ready-react” movements.

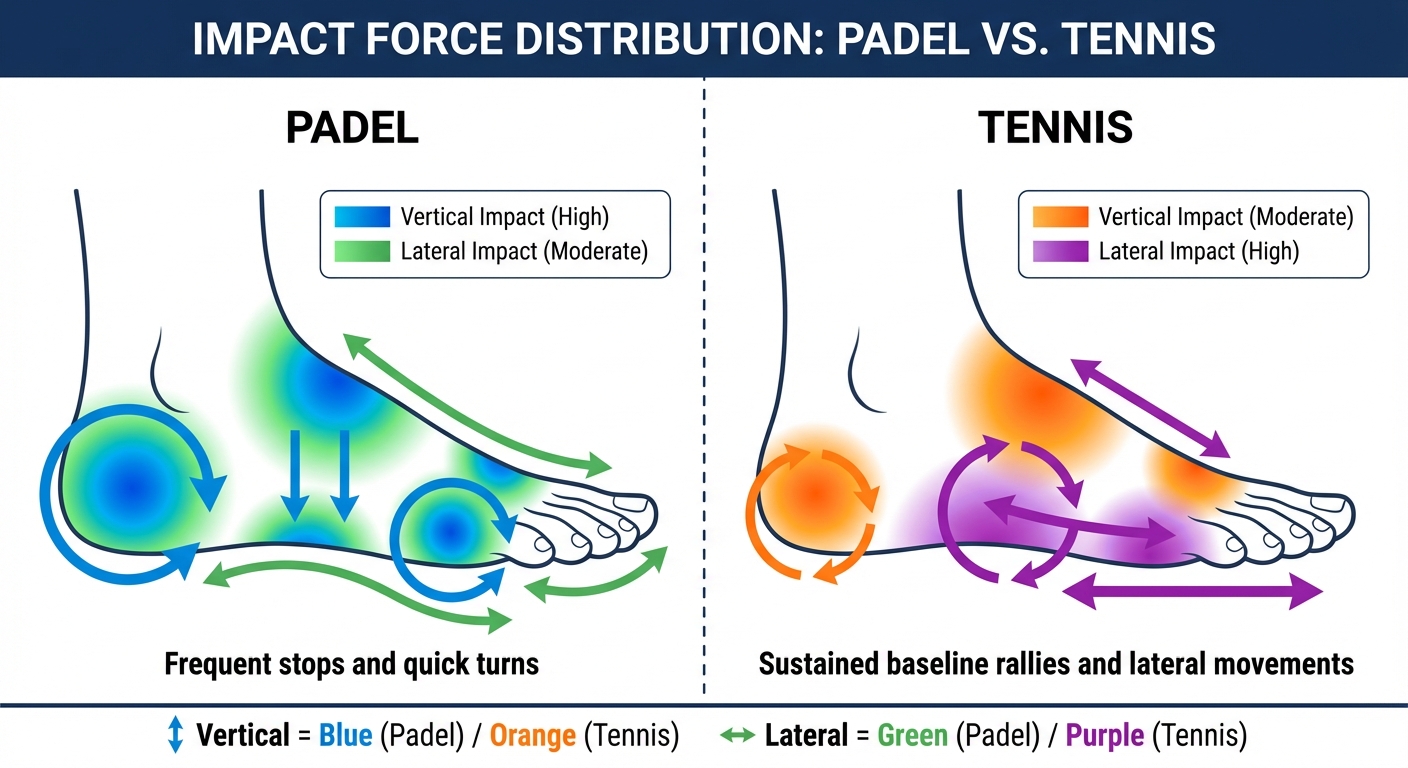

Analyzing the Biomechanics of Padel

In a typical match, a player performs over 300 changes of direction. The engineering process maps these movements to identify three primary stress zones: the lateral forefoot (during pivots), the medial midfoot (during lunges), and the posterior heel (during overhead jumps).

Material Selection for Professional Durability

To build a shoe that survives the abrasive nature of synthetic turf, engineers utilize high-density synthetic skins. These materials are chosen for their high coefficient of friction and resistance to “turf burn.”

- Kevlar-reinforced mesh: Used in high-wear zones to prevent tearing.

- Thermo-polyurethane (TPU) Overlays: Provided for structural “skeletons” that hold the foot in place without adding excessive weight.

Think about it: a shoe is only as good as its weakest bond. That’s why the construction process uses industrial-grade bonding agents that remain flexible under high temperatures, ensuring the Padel Structure of the shoe doesn’t delaminate during intense summer play.

| Component | Technical Specification | Performance Benefit |

|---|---|---|

| Upper Material | High-tenacity engineered mesh | Maximum breathability and heat dissipation |

| Reinforcement | 3D-molded TPU cages | Superior lateral containment |

| Bonding | High-temp industrial adhesive | Prevents sole separation on hot turf |

wilson padel shoes: How do they optimize player stability during high-intensity play?

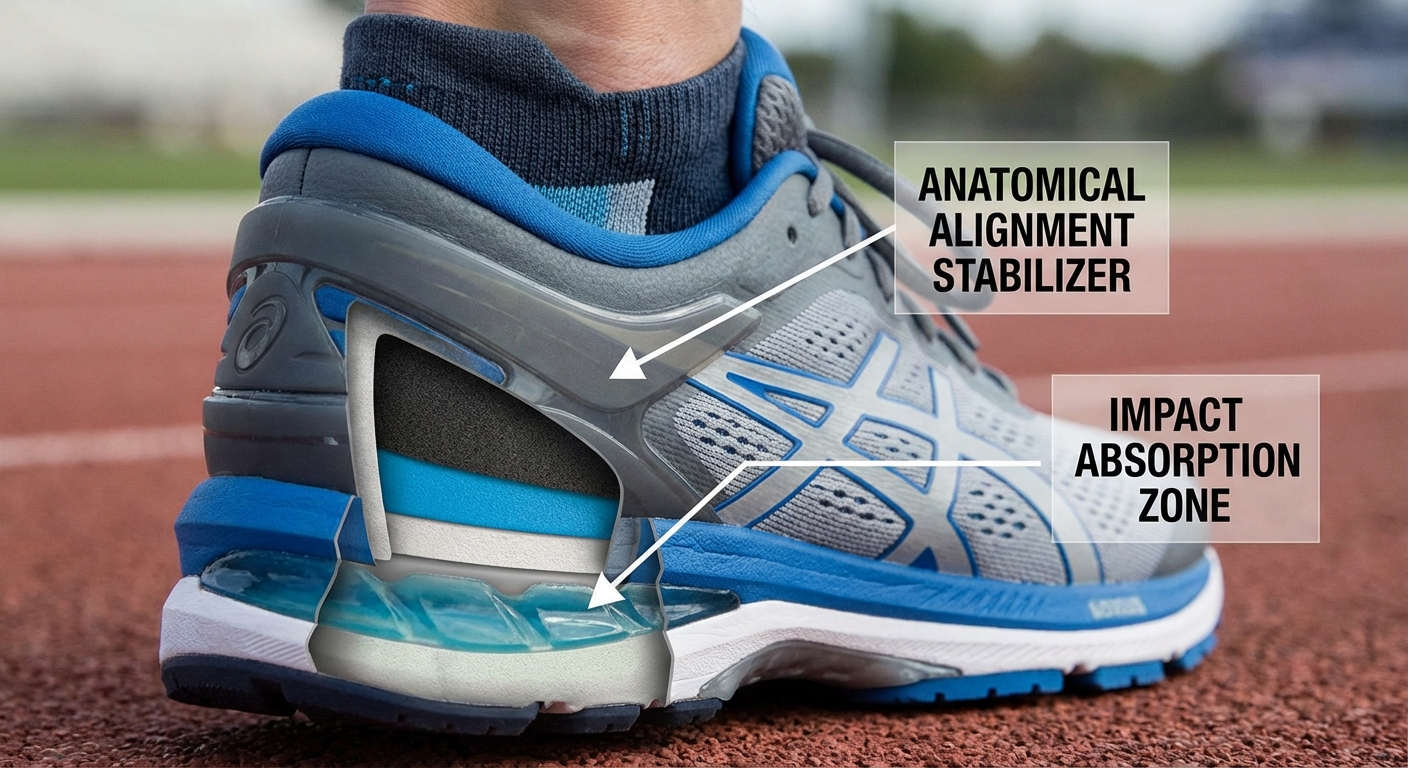

Stability is the cornerstone of player confidence. In the B2B sector, providing stable footwear is a risk-mitigation strategy. Wilson padel shoes employ a dual-chassis system to manage the extreme lateral forces generated when a player pushes off for a cross-court sprint.

Dual Chassis Integration

The “build” involves an internal chassis that mimics the natural flex of the foot’s arch, paired with an external rigid frame. This external frame acts as a “roll bar” in a racing car, preventing the foot from rolling over the edge of the sole during a sudden stop on a Standard Padel Court.

Lateral Support Systems

The truth is, most injuries occur during the “split step.” To counter this, engineers incorporate:

- Extended Outriggers: Widened sections of the outsole that provide a larger footprint for stability.

- Integrated Heel Locking: A molded heel counter that secures the calcaneus (heel bone) to prevent internal slippage.

Wait, there’s more. The stability isn’t just about rigidity; it’s about controlled flexibility. The midfoot is engineered with a torsional shank—a stiff piece of material that prevents the shoe from twisting in the middle while still allowing the forefoot to flex for explosive take-offs.

wilson padel shoes: Why is the outsole tread design crucial for synthetic turf?

The interface between the shoe and the Padel Grass is where matches are won or lost. Traditional herringbone patterns, common in tennis, often provide too much “bite” on padel turf, leading to knee injuries when the foot gets stuck during a turn.

The Evolution of the Circular Tread

Wilson padel shoes feature a revolutionary circular tread design. These “pivot circles” are strategically placed under the ball of the foot and the heel.

- 360-degree Traction: Allows for seamless rotation in any direction.

- Controlled Slide: The rubber compound is calibrated to allow for a “micro-slide,” which dissipates the energy of a hard stop and protects the player’s joints.

Adapting to Surface Variations

Not all courts are created equal. The tread depth in these shoes is specifically designed to clear sand (silica) efficiently, ensuring that the rubber always makes contact with the synthetic fibers. This is particularly important on courts with heavy sand infill where “aquaplaning” on sand is a common hazard.

| Tread Type | Best For | Technical Advantage |

|---|---|---|

| Deep Circular | Heavy Sand Infill | Superior sand displacement and grip |

| Micro-Dot Pattern | Sandless / Mondo Turf | Increased surface area for “sticky” traction |

| Hybrid Chevron | Multi-surface facilities | Balanced grip for transition players |

wilson padel shoes: What cushioning technology is utilized for joint protection?

Padel is a high-impact sport. Unlike tennis, which is predominantly lateral, padel involves a significant amount of vertical movement—jumping for “bandejas” and “smash” shots. This requires a specialized approach to midsole engineering.

High-Rebound Midsole Systems

The midsole of wilson padel shoes is typically constructed from a proprietary blend of EVA (Ethylene Vinyl Acetate) and specialized polymers. This “super-foam” serves two purposes:

- Shock Absorption: Attenuating the force of landing, which can be up to 5x the player’s body weight.

- Energy Return: Using the compressed energy to propel the player into their next movement.

Anatomical Alignment

But it doesn’t stop at foam. Engineers analyze the impact force distribution to place “impact pods” in the heel. These pods are softer than the surrounding midsole, creating a “cradle” for the heel that ensures the foot stays neutrally aligned. This reduces the risk of developing plantar fasciitis, a common ailment for club players.

pie title Impact Force Distribution: Padel vs. Tennis

"Padel (Vertical Impacts)" : 45

"Tennis (Lateral Sprints)" : 35

"Static/Ready Position" : 20

wilson padel shoes: How does professional athlete feedback influence the design?

The engineering of wilson padel shoes is not a laboratory-only endeavor. It is a collaborative process with the world’s elite players who push equipment to its absolute breaking point.

Digital Pressure Mapping

During the development phase, professional athletes wear shoes equipped with ultra-thin sensor insoles. This data provides a “heat map” of stress.

- High-Stress Zones: Often found on the lateral edge of the pinky toe and the medial side of the big toe.

- Engineering Response: These zones are reinforced with extra rubber “wraps” from the outsole, creating a durable shield against toe-dragging.

The “Feel” Factor

Professionals often demand a “low-to-the-ground” feel. This is a technical challenge: how do you provide maximum cushioning while keeping the center of gravity low? The solution is a “drop” (the height difference between heel and toe) of approximately 6-9mm, which is lower than many traditional running shoes, providing a more stable “court feel.”

| Feedback Metric | Athlete Requirement | Engineering Solution |

|---|---|---|

| Court Feel | “I need to feel the turf” | Lowered stack height (midsole thickness) |

| Speed | “The shoe feels heavy” | Introduction of nitrogen-infused foams |

| Durability | “I wear through the toe” | Extended medial drag guards |

wilson padel shoes: What role does court surface evolution play in shoe construction?

As padel court technology advances, footwear must adapt. The move from traditional sand-heavy courts to premium Panoramic Padel Court installations has changed the requirements for traction and cleanliness.

Adapting to Sandless Turf

Modern, high-end facilities often use textured monofilament grass that requires little to no sand. Wilson padel shoes developed for these surfaces use a softer rubber compound (lower Shore A hardness). This allows the outsole to “grip” the synthetic fibers more effectively, providing the traction needed for the fast-paced “pro” style of play.

Non-Marking Requirements

In a B2B environment, facility maintenance is a priority. The “build” of these shoes ensures they are strictly non-marking. This prevents unsightly scuffs on the blue or green turf, as well as on the glass panels of a Super Panoramic Padel Court.

“The synergy between the shoe’s outsole and the turf’s density is the most overlooked factor in player safety and facility longevity.” — Technical Director of Court Infrastructure.

wilson padel shoes: How are materials optimized for weight reduction without sacrificing support?

In the professional world, every gram counts. A shoe that is 50 grams lighter can reduce the total weight lifted by a player by several tons over the course of a three-set match.

Engineered Mesh and Synthetics

To achieve this, wilson padel shoes move away from heavy leathers. Instead, they utilize:

- Variable-Density Knits: Thicker in areas requiring support, thinner in areas requiring breathability.

- Hollow-Core Fibers: Synthetic materials that provide structural strength with air-filled centers to reduce mass.

The Lightweight Chassis

The internal support structures are now often made from carbon-fiber-reinforced polymers. These materials offer the same rigidity as steel or heavy plastics but at a fraction of the weight. This allows the player to maintain their speed in the third hour of a match, reducing the “heavy leg” feeling that leads to errors and injuries.

| Material | Weight Benefit | Strength Rating |

|---|---|---|

| Carbon-Fiber Polymer | Ultra-Light | Elite |

| Engineered Mesh | Light | Moderate (requires overlays) |

| Traditional Leather | Heavy | High |

wilson padel shoes: Can specialized footwear improve a player’s rotational efficiency?

Rotational movement is the “secret sauce” of high-level padel. Whether it’s turning to chase a lob or spinning to hit a ball off the back glass, the ability to rotate efficiently is paramount.

Integrated Pivot Points

The “pivot point” is a circular feature on the outsole, usually located under the first metatarsal head. In wilson padel shoes, this point is engineered with a smoother rubber texture than the rest of the sole.

- Reduced Friction: Minimizes the torque applied to the knee during a turn.

- Precision Alignment: Ensures the player’s center of mass stays over the shoe during the rotation.

Torsional Control

While the foot needs to rotate, it shouldn’t “twist” out of alignment. The build includes a midfoot shank that controls this torsion. It allows the forefoot and heel to move independently while maintaining the structural integrity of the arch. This is critical for defending the corners of a Panoramic Padel Court.

wilson padel shoes: What is the manufacturing process for these technical products?

Manufacturing high-end footwear is a multi-step process that combines robotic precision with artisan finishing. For a B2B purchaser, understanding this process is key to identifying quality.

Injection Molding the Midsole

The process begins with the injection of liquid foam into precision-machined molds. This ensures that the cushioning properties are identical in every shoe. “Cold-pressing” is then used to set the foam, which increases its durability and prevents it from “bottoming out” (losing its bounce) prematurely.

The Lasting Process

The “last” is the anatomical form the shoe is built around. Wilson padel shoes use a specialized padel last that features a slightly wider forefoot and a narrower heel. This anatomical “V” shape is designed to accommodate the foot’s natural expansion during high-heat matches.

Quality Assurance (QA)

Every batch of shoes undergoes rigorous testing, including:

- Flex Test: The shoe is bent 50,000 times to ensure no cracking in the midsole.

- Abrasion Test: The outsole is dragged across an abrasive surface to measure wear rates.

- Bond Test: Ensuring the upper cannot be pulled away from the sole under extreme force.

wilson padel shoes: How to select the correct inventory for your padel facility?

For club owners, stocking the right wilson padel shoes is about more than just aesthetics. It’s about providing a service that enhances the player experience and protects your court investment.

Sizing and Demographic Analysis

A well-stocked pro shop should account for:

- Gender-Specific Lasts: Women’s shoes are typically narrower in the heel and have higher arch support.

- Junior Progression: Specialized shoes for younger players to protect developing joints.

Surface-Matching Strategy

If your club features the latest Standard Padel Court with high sand levels, prioritize shoes with the deep-groove circular pattern. If you have moved to “super-grass” or sandless surfaces, stock the softer-compound models that offer higher surface-area contact.

The Value Proposition

The truth is, a player who feels safe and comfortable will play more often. By offering professional-grade wilson padel shoes, you are positioning your facility as a premium destination that cares about player longevity and performance.

| Inventory Goal | Recommendation |

|---|---|

| Maximize Safety | Stock dual-chassis models with TPU reinforcement |

| Appeal to Pros | Offer lightweight, low-drop models |

| Facility Maintenance | Ensure all stock is 100% non-marking |

Frequently Asked Questions

Why can’t I use running shoes for padel?

Running shoes are designed for linear motion. They lack the lateral stability (chassis) and reinforced uppers needed for padel. Using them significantly increases the risk of ankle rolls and “blowouts” where the foot slides through the mesh side of the shoe.

How long do professional padel shoes typically last?

For a player competing 2-3 times per week, the technical properties of the cushioning usually last 6-8 months. While the shoe may look fine on the outside, the internal foam “fatigues” and loses its ability to protect your joints.

Is there a difference between “clay” tennis outsoles and padel outsoles?

Yes. While both use herringbone or circular patterns, padel-specific outsoles are often slightly shallower and use a different rubber density to account for the synthetic turf fibers versus the loose dust of a clay court.

Do I need different shoes for indoor and outdoor courts?

Generally, no. However, outdoor courts may accumulate more dust and environmental debris, meaning you may need to clean the outsoles more frequently to maintain optimal grip. Indoor players might prefer shoes with more mesh for better ventilation.

How should a professional padel shoe fit?

It should be “snug but not tight.” There should be about a thumbnail’s width of space at the toe to allow for the foot to slide forward slightly during hard stops without bruising the toenails. The heel must be perfectly locked in with zero vertical slippage.

Elevate your game and your facility’s standards by investing in footwear engineered for the modern court. Contact us today to discuss professional court installations and equipment strategies for your club.