A paddel court is a specialized sports facility measuring 10×20 meters, enclosed by glass and mesh, and built by preparing a solid foundation followed by precise structural assembly. You might notice the massive growth of racket sports but struggle to find the right entry point for your own facility. Ignoring this trend means leaving significant revenue on the table while competitors capture your local market. A professional paddel court is the definitive solution for high-density player engagement and long-term commercial success.

What# Paddel Court: What It Is and How to Build It

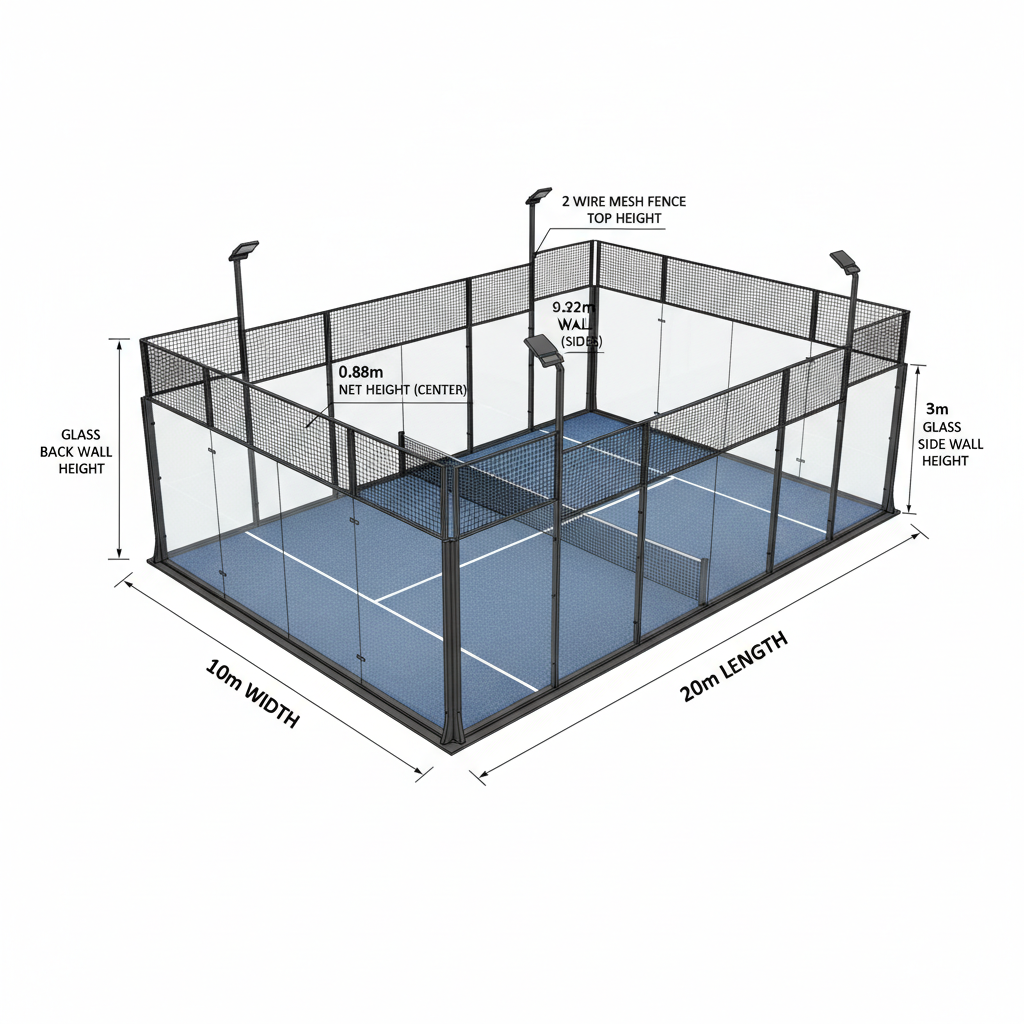

A paddel court is an enclosed rectangular playing surface measuring 10 meters by 20 meters, surrounded by glass walls and metal mesh, where you play doubles tennis with walls. Building one requires specialized artificial turf, tempered glass panels, hot-dip galvanized steel framing, LED lighting, and a properly engineered foundation with drainage—typically taking 4-6 weeks from site preparation to final installation.

You’ve watched paddel explode across Europe and now you’re considering building your own court. Here’s the problem: most facility owners waste 20-30% of their budget on incorrect specifications, substandard materials, or foundation issues that surface within the first year. The agitation? These mistakes don’t just cost money—they create liability risks, member complaints, and costly repairs that could have been avoided. The solution lives in understanding exactly what a paddel court demands from the ground up, and how professional-grade construction delivers return on investment through decades of reliable performance.

What Makes a Paddel Court Different From Tennis?

A paddel court distinguishes itself through its compact dimensions and integrated wall play, fundamentally changing the game’s dynamics compared to traditional tennis. The 10×20-meter rectangle—exactly one-quarter the size of a tennis court—creates faster rallies and demands quick reflexes. Every paddel court incorporates walls as active playing surfaces, not boundaries, transforming defensive positions into offensive opportunities through strategic wall rebounds.

Core Structural Requirements

Think about it: walls aren’t optional decorations.

The International Padel Federation mandates 12mm tempered glass meeting EN 12150 safety standards for the lower 3 meters of wall height. This glass must withstand repeated high-velocity ball impacts while remaining transparent enough for spectator viewing. Above the glass, black metal mesh extends another 1-2 meters, creating the full enclosure height of 4 meters at the back wall.

The playing surface demands equally rigorous specifications. Here’s the deal: not all artificial turf performs equally. Premium courts use high-density, fibrillated turf with silica sand infill, achieving the precise ball bounce characteristics that define professional play. The surface must provide adequate traction while allowing smooth lateral movement and cushioning player joints during explosive directional changes.

Net and Line Specifications

The net stands 88cm high at the center point, rising to 92cm at the posts. Black tape marks the top edge, and the mesh size prevents ball passage while maintaining visibility. White boundary lines—10cm wide—delineate service boxes and sidelines with precision. These lines aren’t painted but rather integrated into the turf during manufacturing, ensuring they won’t fade or require repainting.

Key Takeaway: The physical specifications aren’t arbitrary—each measurement reflects years of gameplay refinement optimizing player safety, ball dynamics, and competitive balance that makes paddel accessible yet challenging for all skill levels.

| Feature | Specification | Purpose |

|---|---|---|

| Court Dimensions | 10m × 20m | Optimal play area for doubles matches |

| Glass Wall Height | 3m (12mm tempered) | Safety + Ball rebound consistency |

| Net Center Height | 88cm | Balanced offensive/defensive play |

| Surface Material | Fibrillated artificial turf | Controlled ball bounce + player traction |

This configuration creates the distinctive gameplay that’s driven paddel’s global growth beyond 18 million players.

How Do Standard Courts Compare to Panoramic Designs?

Standard paddel courts utilize a combination of glass front walls and metal mesh back walls, while panoramic padel courts feature floor-to-ceiling glass on all four sides without rear structural posts. The panoramic design costs 20-30% more but delivers unobstructed sightlines that enhance spectator experience and justify premium pricing at competitive venues.

Visual Impact and Player Experience

Look: the difference hits you immediately when you step onto the court.

Standard courts employ 3-meter glass walls at the front with metal mesh comprising the upper sections and entire back wall. This design provides adequate functionality for recreational play while controlling costs. The mesh sections, while durable, create visual barriers that segment the playing space and limit viewing angles for spectators positioned behind the court.

Panoramic courts eliminate these visual obstructions entirely. Floor-to-ceiling tempered glass panels wrap the entire perimeter, secured by minimal metal framing only at the corners and top edges. Players report feeling more “open” despite the same 10×20-meter footprint. Tournament directors favor panoramic designs because television cameras capture action from any angle without mesh interference, and sponsors’ signage remains visible throughout broadcasts.

Structural Engineering Differences

Why does this matter? The engineering challenges multiply with panoramic construction.

Standard courts distribute structural loads across both glass and metal mesh sections, with vertical posts every 3 meters providing intermediate support. The rear mesh wall actually reduces wind load and simplifies foundation requirements. Panoramic courts must achieve structural stability using only corner posts and the inherent strength of the glass panels themselves, requiring thicker glass (often 12mm versus 10mm), more robust corner posts, and advanced anchoring systems.

Key Takeaway: Choose standard courts for cost-effective recreational facilities, but invest in panoramic designs when targeting tournament hosting, premium memberships, or venues where the facility itself becomes a marketing differentiator that commands higher pricing.

| Design Type | Glass Coverage | Cost Premium | Best Application |

|---|---|---|---|

| Standard | Front walls only | Baseline | Community centers, schools, entry-level clubs |

| Panoramic | Four-sided glass | +20-30% | Tournament venues, luxury resorts, premium clubs |

| Super Panoramic | Enhanced aesthetics | +35-40% | Flagship facilities, championship venues |

The super panoramic padel court pushes design further with curved glass corners and architectural lighting integration.

What Materials Form the Foundation of Quality?

Quality paddel court construction begins with hot-dip galvanized steel framing, 12mm EN 12150-certified tempered glass, UV-stabilized artificial turf with silica sand infill, and IP66-rated LED floodlights. These materials—selected to withstand 20+ years of intensive use and weather exposure—form the non-negotiable baseline for any paddel court that will deliver reliable performance and manageable maintenance costs.

Steel Framework Components

Here’s the deal: the frame determines everything that follows.

The structural skeleton employs 80x80mm or 100x100mm square hollow steel tubing, hot-dip galvanized to achieve 100+ microns zinc coating thickness. This coating protects against corrosion in humid, chlorinated, or coastal environments. Modular design allows for pre-fabrication and faster on-site assembly—sections bolt together rather than requiring extensive field welding. Corner posts, glass mounting channels, and roof trusses (for covered courts) all integrate into this unified system.

Premium manufacturers specify structural steel grades S235JR or higher, ensuring adequate yield strength to resist wind loads, impact forces, and thermal expansion cycles. The frame must remain dimensionally stable across temperature ranges from -20°C to +60°C without warping or creating gaps in glass mounting tolerances.

Glass and Mesh Specifications

It gets better: material quality directly correlates with player safety.

Tempered glass panels measure 12mm thick minimum, heat-treated to achieve 5x the strength of standard glass. Upon impact, tempered glass fractures into small, relatively harmless cubes rather than dangerous shards. Panels attach using continuous aluminum or steel channels with EPDM gaskets, allowing 3-5mm thermal expansion while maintaining weathertight seals.

The metal mesh sections—positioned above glass walls and at the rear—use 50x50mm or 45x45mm aperture black powder-coated wire mesh. Wire diameter typically measures 3-4mm, providing rigidity without excessive weight. Black powder coating prevents rust and reduces glare for players. Quality mesh maintains tension without sagging, even after years of ball impacts.

Playing Surface Materials

Think about it: every rally begins and ends at the surface.

Premium paddel grass utilizes mono-filament or fibrillated polyethylene fibers, 12-15mm pile height, with 14,000-18,000 stitches per square meter density. This construction provides the optimal ball bounce coefficient (0.45-0.55) mandated by FIP regulations. Silica sand infill (15-20 kg/m²) adds weight, stabilizes fibers, and improves drainage through the permeable backing. UV stabilizers protect fibers from degradation under intense sunlight.

The backing system typically employs double-layer construction: a primary weave for turf attachment, plus a polyurethane coating creating a waterproof yet permeable membrane. This allows rapid drainage (60+ liters/m²/hour) while preventing weed growth from below.

Key Takeaway: Cutting costs on materials always backfires—substandard glass cracks under impact, cheap turf compacts within 18 months, and unprotected steel corrodes rapidly, requiring complete replacement rather than gradual maintenance that quality materials allow.

| Component | Specification | Lifespan | Maintenance Frequency |

|---|---|---|---|

| Steel Frame | 100+ micron galvanizing | 25+ years | Annual inspection |

| Tempered Glass | 12mm EN 12150 | 20+ years | Weekly cleaning |

| Artificial Turf | 15mm pile, UV-stable | 8-12 years | Quarterly grooming |

| LED Lighting | 500W IP66 fixtures | 50,000+ hours | Semi-annual cleaning |

These specifications ensure Padel LED Lighting and other components meet professional standards.

Where Do You Start With Site Preparation?

Site preparation begins with comprehensive soil testing to determine load-bearing capacity, followed by precise excavation to 300-400mm depth, installation of a crushed stone base layer, and construction of perimeter drainage systems before any paddel court structural components arrive. This foundation work represents 30-40% of total project costs but prevents the structural failures that plague improperly prepared installations.

Geotechnical Assessment and Grading

Look: rushing site prep is the #1 reason courts fail prematurely.

Professional installation begins with soil boring tests at 5-meter intervals across the proposed court footprint. Engineers analyze bearing capacity, soil composition, water table depth, and potential for settlement or heaving. Clay-heavy soils require stabilization treatments or deeper excavation to reach suitable load-bearing strata. Rocky terrain might need blasting or imported fill—add 15-25% to budgets when site tests reveal challenging conditions.

Grading establishes the precise elevation and slope required for drainage. Courts must slope 1-2% (10-20mm per meter) from the back wall toward drainage channels at the front. Laser-guided grading equipment achieves ±5mm tolerance across the entire playing surface. Any low spots create puddles that damage turf and compromise play quality.

Base Layer Construction

Why does this matter? The base determines whether your court lasts 5 years or 25.

Excavation removes topsoil and unsuitable materials to 300-400mm depth. Geotextile fabric lines the excavation, preventing subsurface soil migration into the base aggregate. A 200mm layer of crushed angular stone (typically 40-60mm diameter) provides the load-bearing foundation, compacted in 75mm lifts to achieve 95% Modified Proctor density.

Above this, a 50mm layer of smaller crushed stone (10-20mm) creates the leveling course. Mechanical compactors (plate compactors or vibratory rollers) work over the base multiple times, adding moisture as needed to achieve optimal compaction. Under-compacted bases settle unevenly, creating surface irregularities that cannot be corrected without complete reconstruction.

Drainage System Integration

It gets better: proper drainage extends surface life by 40-60%.

Perimeter drainage channels intercept surface runoff before it undermines foundations. These channels typically measure 200mm wide by 300mm deep, lined with slotted PVC or HDPE drainage pipe surrounded by pea gravel and wrapped in geotextile fabric. The system connects to storm sewers or drainage swales, with sufficient fall (minimum 0.5%) to ensure positive drainage.

In high-rainfall regions, subsurface drainage beneath the entire court footprint might be necessary. Herringbone or grid patterns of perforated pipe, spaced 3-5 meters apart, collect water migrating through the base layers and route it to perimeter collectors. Poor drainage accelerates base layer deterioration and can cause structural posts to heave or settle differentially.

Key Takeaway: Site preparation isn’t glamorous work, but it’s the difference between a court that performs flawlessly for decades versus one requiring constant repairs and premature replacement—invest the time and budget here, or pay multiples later.

| Preparation Phase | Depth/Specification | Critical Function | Consequence if Skipped |

|---|---|---|---|

| Soil Testing | 1-2 meters depth | Identify load capacity | Foundation failure, settlement |

| Excavation | 300-400mm | Remove unsuitable material | Uneven settling, surface cracks |

| Base Aggregate | 200mm compacted stone | Load distribution | Posts tilt, glass frames crack |

| Drainage System | Perimeter + subsurface | Water management | Turf deterioration, base erosion |

This foundation supports every component from Padel Glass panels to lighting towers.

How Does the Construction Sequence Progress?

Construction follows a strict sequence: foundation completion, steel frame erection, glass and mesh wall installation, playing surface laying, net and lighting system mounting, then final inspections. This phased approach—typically spanning 4-6 weeks for standard padel courts—prevents rework and ensures each component integrates correctly before subsequent phases begin.

Steel Frame Assembly

Think about it: precision in framing determines every subsequent measurement.

Frame installation begins with corner posts, set into foundation sleeves or bolted to embedded steel plates. Laser levels verify vertical alignment within ±3mm tolerance across the full 4-meter height. Horizontal base beams connect the corner posts, creating the rectangular perimeter. These base beams must achieve perfect level (±2mm across 20 meters) because they define the finished floor plane.

Vertical intermediate posts install at 3-meter spacing along the sides, with glass mounting channels welded or bolted to these posts. The roof truss system (for covered courts) attaches to the top of perimeter posts. All connections use high-strength bolts—typically grade 8.8 or 10.9—torqued to manufacturer specifications. Any welding receives galvanized spray coating to restore corrosion protection at weld zones.

Glass and Mesh Installation

Here’s the deal: wall installation requires crane precision and specialized tooling.

Glass panels—each weighing 150-200kg—arrive on site crated and protected. Mobile cranes or forklift attachments position panels into mounting channels. Installers secure panels using continuous aluminum clamping extrusions and EPDM gaskets, maintaining 3-5mm gaps between adjacent panels for thermal expansion. Structural silicone sealant fills gaps, creating weatherproof joints while allowing movement.

Each panel undergoes inspection for chips, cracks, or manufacturing defects before installation—damaged glass is rejected. The bottom edge sits in a U-channel with drainage holes, preventing water accumulation. Metal mesh sections install above the glass, stretched taut and fastened to the steel framework using special clips or bolted connections that maintain tension.

Surface and Finishing Components

It gets better: the playing surface transform raw structure into a functional court.

A permeable geotextile layer covers the compacted base, followed by the artificial turf. Turf rolls—typically 4 meters wide—unroll across the court surface with seams running perpendicular to the direction of play (avoiding center-court seams where possible). Specialized adhesive tape or sewn seams join adjacent rolls. The turf extends 10-15cm beyond the court perimeter for anchoring.

After turf placement, silica sand infill distributes across the surface using mechanical spreaders, achieving the specified 15-20 kg/m² density. Power brooms work the sand into the fiber base. White court lines (pre-inlaid in the turf or applied as separate turf strips) mark boundaries precisely. Net posts install with ground sleeves, and the net stretches between them at regulation height.

Lighting towers erect last, with electrical conduits running underground from power sources. LED fixtures mount on adjustable brackets, aimed to achieve 500-800 lux illumination uniformly across the playing surface without creating glare zones or dark shadows.

Key Takeaway: Each construction phase builds upon previous work—attempting to skip steps or work out of sequence compounds errors exponentially and often requires tearing out completed work to correct foundational issues discovered too late.

| Construction Phase | Duration | Critical Dependencies | Quality Checkpoint |

|---|---|---|---|

| Steel Frame | 3-5 days | Foundation cure complete | Vertical/horizontal alignment ±3mm |

| Glass Installation | 2-3 days | Frame inspection passed | Panel seating, gap uniformity |

| Surface Laying | 2-3 days | Wall completion | Turf tension, seam quality |

| Final Systems | 2-4 days | Surface installation | Lighting uniformity, net tension |

Professional installation by experienced crews dramatically reduces timeline and ensures specifications like those at Roofed Padel Court projects are met consistently.

What Investment Does Building a Court Require?

A professional-grade paddel court costs $35,000-$75,000 for materials and installation, with standard courts at the lower range and panoramic designs commanding premium pricing. These figures cover all essential components—steel frame, glass walls, artificial surface, lighting, and installation labor—but exclude site preparation costs that vary dramatically based on ground conditions and location.

Material Cost Breakdown

Look: understanding cost drivers helps optimize budget allocation.

The steel frame structure represents 20-25% of total costs ($7,000-$18,000), varying with design complexity and galvanizing quality. Glass panels comprise 25-30% ($8,000-$22,000), with panoramic designs requiring 40% more glass area than standard courts. Premium 12mm tempered glass costs $150-$250 per square meter installed, while lower-grade 10mm panels might be $100-$150 per square meter but compromise safety margins.

Artificial turf and infill account for 15-20% ($5,000-$12,000), depending on fiber quality, pile density, and backing system. Professional-grade LED lighting systems range $3,000-$8,000, with higher-end fixtures offering better energy efficiency and longer lifespans. Metal mesh, net system, and fasteners add another $4,000-$8,000.

Labor and Installation Expenses

Think about it: skilled installation prevents costly rework.

Professional installation labor typically equals 25-35% of material costs, or $9,000-$25,000 for a complete court. This includes crane rental, specialized tools, and experienced crews capable of working to tight tolerances. Self-installation or hiring unqualified contractors might save 50% on labor but often results in structural issues requiring complete reconstruction—a false economy.

Regional variations significantly impact labor rates. Metropolitan areas with high construction costs might see labor premiums of 40-60% above rural regions. However, traveling installers from distant locations incur mobilization costs that offset these differences. The optimal approach typically involves sourcing materials globally from specialized manufacturers while engaging qualified local contractors for installation.

Budget Optimization Strategies

Why does this matter? strategic decisions stretch budgets without compromising quality.

Bulk purchasing—ordering multiple courts simultaneously—leverages economies of scale, reducing per-court costs by 10-20%. Standardizing designs across multiple courts simplifies procurement and installation. Phasing projects over 12-18 months spreads capital expenditure while allowing revenue generation from initial courts to fund subsequent phases.

Consider modular or prefabricated systems that reduce on-site labor intensity. Some manufacturers offer complete frame and glass assemblies that bolt together in 2-3 days rather than requiring extensive field fabrication. While unit costs might be 5-10% higher, total project costs decrease through accelerated installation and reduced crane time.

Key Takeaway: Budget $50,000-$65,000 for a quality standard court including contingencies, or $65,000-$95,000 for panoramic designs—attempting to cut below these thresholds inevitably compromises specifications that determine long-term performance and safety.

| Cost Category | Standard Court | Panoramic Court | Budget Percentage |

|---|---|---|---|

| Steel Frame | $7,000-$15,000 | $10,000-$18,000 | 20-25% |

| Glass/Mesh Walls | $8,000-$18,000 | $15,000-$22,000 | 25-30% |

| Playing Surface | $5,000-$10,000 | $6,000-$12,000 | 15-20% |

| Lighting System | $3,000-$7,000 | $5,000-$8,000 | 8-12% |

| Installation Labor | $9,000-$20,000 | $15,000-$25,000 | 25-35% |

Premium suppliers like SuperbPadel offer factory-direct pricing that eliminates distributor markups, potentially saving 15-30% on material costs.

Which Permits and Regulations Govern Construction?

Building a paddel court requires compliance with local zoning ordinances, building permits, electrical permits, and sometimes conditional use permits, plus adherence to FIP (International Padel Federation) technical regulations if hosting sanctioned competitions. The permitting process—often taking 6-12 weeks—must begin before site work commences to avoid construction delays and potential legal complications.

Zoning and Land Use Requirements

Here’s the deal: zoning violations can halt projects completely.

Municipal zoning codes classify land use into residential, commercial, recreational, or mixed-use categories. Paddel courts typically require recreational or commercial zoning approval. Residential properties might need variance applications demonstrating minimal neighborhood impact regarding noise, lighting, and traffic. Setback requirements—minimum distances from property lines—range from 3-10 meters depending on jurisdiction.

Height restrictions pose challenges for lighting towers, which typically extend 6-8 meters above finished grade. Some municipalities classify sports lighting as a separate category requiring additional review. Covered courts might trigger different building code requirements than uncovered facilities, potentially necessitating architectural stamped drawings and structural engineering certifications.

Building and Safety Codes

It gets better: code compliance protects liability and insurability.

Building permits verify that construction plans meet structural, electrical, and safety standards. Inspectors review foundation design, steel frame specifications, and glass mounting systems. The International Building Code (IBC) or local equivalents mandate wind load calculations, seismic considerations in earthquake-prone regions, and emergency egress planning for enclosed facilities.

Electrical permits cover lighting circuit installation, ensuring proper grounding, circuit breaker sizing, and conduit routing. Courts operating during evening hours require compliance with light pollution ordinances limiting spillover onto adjacent properties. Many jurisdictions now mandate dark-sky compliant fixtures with cutoff angles preventing upward light emission.

Sports Facility Certifications

Look: tournament hosting requires federation compliance.

The International Padel Federation publishes detailed technical specifications that govern court dimensions, materials, and construction tolerances. FIP certification—while not legally required—becomes essential for venues seeking to host regional, national, or international tournaments. The certification process involves independent inspectors measuring court dimensions (tolerances ±20mm), testing glass strength, and verifying lighting uniformity.

European markets often require additional CE marking on glass panels and structural components. North American markets might need products certified to ASTM standards for sports surfaces and safety glazing. Insurance carriers increasingly scrutinize these certifications when underwriting sports facility policies, potentially denying coverage for non-certified installations.

Key Takeaway: Engage permit consultants or expeditors early in planning phases—their expertise navigating regulatory processes prevents costly delays and ensures applications include all required documentation the first time, accelerating approvals from months to weeks.

| Permit Type | Processing Time | Key Requirements | Failure Consequence |

|---|---|---|---|

| Zoning Approval | 4-8 weeks | Land use compliance, setbacks | Project rejection, relocation |

| Building Permit | 3-6 weeks | Structural plans, code compliance | Construction halt, penalties |

| Electrical Permit | 1-2 weeks | Licensed contractor, plans | No power connection |

| FIP Certification | 2-4 weeks | Dimensional accuracy, materials | Tournament ineligibility |

Working with experienced suppliers familiar with local requirements, such as those at SuperbPadel’s about page, streamlines the permitting process significantly.

How Do You Maintain Long-Term Performance?

Maintaining a paddel court requires weekly surface sweeping and glass cleaning, quarterly turf grooming with mechanical brushes, annual steel frame inspections for corrosion, and lighting system checks every six months. This systematic maintenance program—costing $2,000-$4,000 annually—preserves the $50,000-$75,000 investment and ensures consistent playing conditions that keep members satisfied and returning.

Daily and Weekly Maintenance Tasks

Think about it: small actions compound into long-term preservation.

Daily visual inspections identify hazards before play begins—loose net tensioning, debris on the playing surface, cracked glass panels, or malfunctioning lights. Sweeping removes leaves, dirt, and organic matter that accelerate turf degradation. Magnetic sweepers capture metal fragments (screws, wire pieces) that could puncture balls or injure players.

Weekly glass cleaning uses squeegees and approved cleaning solutions that don’t leave residue compromising transparency. Avoid abrasive cleaners or stiff brushes that scratch glass surfaces. Clean from top to bottom, rinsing thoroughly to prevent soap film accumulation. Inspect rubber gaskets and sealant joints for gaps or deterioration allowing water infiltration.

Seasonal Maintenance Protocols

Why does this matter? seasonal cycling accelerates specific wear patterns.

Quarterly turf grooming redistributes infill material, restoring uniform depth across high-traffic areas (service boxes, net zones). Mechanical brushes stand up compacted fibers, maintaining pile height and ensuring consistent ball bounce. Power brooms work perpendicular to fiber direction, lifting and separating individual blades. Add additional infill (1-2 kg/m²) to areas showing depletion.

Annual steel frame inspections focus on joints, welds, and anchor points. Look for rust bloom indicating coating failure, loose bolts requiring re-torquing, or structural deflection suggesting overloading or foundation settlement. Apply galvanized touch-up paint to any exposed steel surfaces. Tighten or replace worn fasteners before they fail catastrophically.

Lighting maintenance includes lens cleaning (removing dust and insect accumulation), fixture alignment verification, and driver/ballast testing. LED systems degrade gradually—track operating hours and replace fixtures approaching 50,000-hour service life before complete failure. Clean solar panels (if installed) quarterly to maintain charging efficiency.

Repair and Replacement Considerations

Look: proactive replacement prevents emergency shutdowns.

Minor glass chips (under 30mm diameter, not penetrating both surfaces) can remain in service with monitoring, but cracks exceeding 100mm or reaching panel edges require immediate replacement. Keep spare glass panels on-site for rapid response—waiting for custom orders extends closure periods from days to weeks.

Turf reaches end-of-life when fibers permanently compress, backing deteriorates, or infill retention fails despite grooming. Expect replacement every 8-12 years depending on usage intensity. Partial repairs (patching worn areas) prove cost-ineffective—inconsistent surface characteristics create trip hazards and uneven ball response.

Key Takeaway: Budget 3-5% of replacement cost annually for maintenance—$1,500-$3,750 per court—and implement documented maintenance schedules that track all service activities, creating historical records proving diligent stewardship that protects insurance coverage and resale value.

| Maintenance Task | Frequency | Time Required | Annual Cost |

|---|---|---|---|

| Surface Sweeping | Daily | 15 minutes | Included in operations |

| Glass Cleaning | Weekly | 45 minutes | $500-$800 (outsourced) |

| Turf Grooming | Quarterly | 2 hours | $400-$800 |

| Frame Inspection | Annual | 3 hours | $300-$600 |

| Lighting Service | Semi-annual | 2 hours | $400-$800 |

Detailed maintenance protocols are available from manufacturers like SuperbPadel as part of post-installation support.

What Mistakes Derail Court Projects Most Often?

The most common paddel court construction mistakes include inadequate foundation preparation causing settlement, using non-certified glass that fails safety standards, incorrect court orientation creating sun glare issues, and insufficient drainage leading to water accumulation. These errors—typically resulting from cost-cutting or inexperienced contractors—transform what should be 20+ year investments into constant maintenance nightmares requiring premature replacement.

Foundation and Drainage Failures

Here’s the deal: visible court problems almost always trace to invisible foundation issues.

Under-compacted base layers settle unevenly within 6-18 months, creating surface depressions ranging from subtle (affecting ball roll) to severe (causing pooling water). The ripple effects cascade: turf buckles, steel posts tilt, glass frames crack from differential movement. Correcting these failures requires excavating the entire court, rebuilding the base, and reinstalling all components—essentially starting over at 80-90% of original construction cost.

Inadequate drainage proves equally destructive. Courts without perimeter drains experience water infiltration beneath the base, saturating stone aggregate and reducing its load-bearing capacity. Freeze-thaw cycles in cold climates heave foundations, while constant moisture in warm climates breeds algae and mold that colonize turf backing. The solution requires retrofitting drainage systems by cutting through finished surfaces—disruptive, expensive, and completely avoidable through proper initial design.

Material and Specification Compromises

Think about it: cheap materials cost more in the long run.

Non-certified glass represents the most dangerous compromise. Standard annealed glass—rather than tempered safety glass—might save 40% initially but shatters into large, razor-sharp shards upon impact, creating severe injury liability. Some suppliers offer “tempered” glass not meeting EN 12150 standards, failing certification inspections and requiring complete replacement before tournament hosting.

Substandard artificial turf degrades within 3-5 years rather than 8-12, exhibiting fiber breakage, backing deterioration, and infill compaction that creates unplayable conditions. The cost differential—$20-$30 per square meter—seems significant during procurement but pales against premature replacement costs and lost revenue during extended closures.

Undersized or uncoated steel framing corrodes rapidly, particularly in humid or coastal environments. Surface rust appears within 12-24 months, progressing to structural corrosion requiring frame replacement. The “savings” from 75-micron galvanizing versus 100-micron coating disappears within five years when rust remediation begins.

Site Planning and Orientation Errors

Why does this matter? poor orientation ruins playability despite perfect construction.

Court orientation critically affects sun glare during play. The ideal north-south axis minimizes direct sun in players’ eyes during morning and evening peak play times. East-west orientation creates severe glare problems during serve at sunrise and sunset, when low-angle sun streams directly down court length. Rotating courts just 20-30 degrees from ideal angles might seem inconsequential but generates persistent player complaints.

Proximity to trees or tall structures creates shade patterns that cause uneven surface temperatures, affecting ball bounce characteristics. Overhanging branches drop debris requiring constant cleaning and pose branch-fall hazards during storms. Insufficient setbacks from property lines generate neighbor complaints about noise (ball impacts on glass) and lighting (spillover into residential yards), potentially triggering legal actions or municipal violations.

Key Takeaway: Hire experienced contractors with verifiable paddel court portfolios—their premium fees (10-20% over general contractors) prevent mistakes costing 200-500% more to remediate, while ensuring installations meet specifications supporting decades of reliable service.

| Common Mistake | Initial Cost “Savings” | Remediation Cost | Long-term Impact |

|---|---|---|---|

| Poor Foundation | 15-25% | 80-100% of original | Complete reconstruction |

| Non-certified Glass | 30-40% | 100% (full replacement) | Liability exposure, no tournaments |

| Cheap Artificial Turf | 20-30% | 60-80% after 3-5 years | Lost revenue, reputation damage |

| Wrong Orientation | N/A (planning error) | Cannot fix (rebuild) | Persistent player complaints |

Professional consultation services from established manufacturers prevent these pitfalls—contact us today for site evaluation.

Can You Build a Court in Your Backyard?

You can build a paddel court in your backyard if your property provides at least 11×21 meters of flat space (including safety zones), local zoning permits recreational structures, and you obtain necessary building permits. Backyard courts cost the same as commercial installations—$50,000-$75,000—but face additional challenges around neighbor concerns, property value impacts, and ongoing maintenance responsibilities typically handled by facility staff at clubs.

Space and Access Requirements

Look: raw square meters only tell part of the story.

The 10×20-meter court footprint expands to 11×21 meters minimum when including mandatory 0.5-meter safety zones on all sides. Add another 2-3 meters for maintenance access, spectator areas, and equipment storage. The total practical footprint ranges 15×25 meters (375 m²) to 20×30 meters (600 m²) depending on amenities.

Access for construction equipment—particularly cranes and concrete trucks—requires minimum 3-meter-wide pathways from the street to the build site. Properties with narrow side yards, overhead power lines, or limited turning radius complicate or prevent machinery access, forcing manual material handling that inflates labor costs by 50-100%.

Overhead clearance matters equally. Tall trees overhanging the proposed court location require pruning or removal. While trees provide aesthetic value and shade, falling branches, leaf accumulation, and root intrusion beneath foundations create ongoing problems. Budget $2,000-$8,000 for tree work depending on size and quantity.

Residential Permitting Challenges

It gets better: residential permits involve neighbors in approval processes.

Many jurisdictions require notifying adjacent property owners of proposed recreational structure construction, allowing them to file objections or concerns. Common complaints center on noise—ball impacts on glass create sharp “pock” sounds audible 50-100 meters away—and lighting extending playing hours into evening when neighbors desire quiet.

Homeowner Association (HOA) covenants frequently restrict large structures, outdoor sports facilities, or activities generating noise/light. Review CC&Rs (Covenants, Conditions & Restrictions) before investing in planning. Some HOAs prohibit commercial-grade sports facilities entirely, while others require architectural committee approval involving subjective aesthetic judgments potentially rejecting projects capriciously.

Variance applications—when standard zoning prohibits sports courts—demand demonstrating the structure won’t negatively impact neighbors or property values. This process can extend 3-6 months and might require hiring land use attorneys ($3,000-$10,000) to navigate hearings and appeals.

Practical Considerations

Think about it: ownership means assuming all operational responsibilities.

Unlike club courts with dedicated maintenance staff, backyard owners handle all cleaning, repairs, and seasonal upkeep personally or contract services at commercial rates. The annual $2,000-$4,000 maintenance budget becomes real money leaving personal accounts, not absorbed into facility operating budgets.

Insurance considerations shift dramatically. Homeowner policies might exclude sports facilities or limit liability coverage inadequately for injury claims. Separate sports facility insurance—if obtainable for residential installations—costs $1,000-$3,000 annually. Some insurers refuse coverage entirely for backyard courts, forcing owners into high-risk pools with premium rates.

Resale value impacts cut both ways. Paddel-playing buyers view courts as tremendous amenities, potentially adding $30,000-$50,000 to perceived value. Non-playing buyers might see courts as costly-to-remove obstacles occupying desirable lawn space, actually decreasing property appeal. The net effect depends heavily on local market demographics and paddel participation rates.

Key Takeaway: Backyard courts make financial sense for serious paddel enthusiasts hosting regular games with friends, particularly in regions where club access is limited—but treat it as a lifestyle investment, not a financial one, recognizing you’re building something you love rather than something guaranteed to appreciate property value.

| Consideration | Requirement | Typical Cost Impact | Success Factor |

|---|---|---|---|

| Property Size | 15x25m minimum | N/A | Must meet minimum |

| Access for Equipment | 3m pathway, no overhead | +$0-$15,000 if restricted | Critical for construction |

| Neighbor Relations | Notification, noise tolerance | Variable (legal fees) | Can halt project |

| Ongoing Maintenance | DIY or contracted services | $2,000-$4,000/year | Determines long-term viability |

Residential installations require careful planning—contact us for site-specific feasibility assessment.

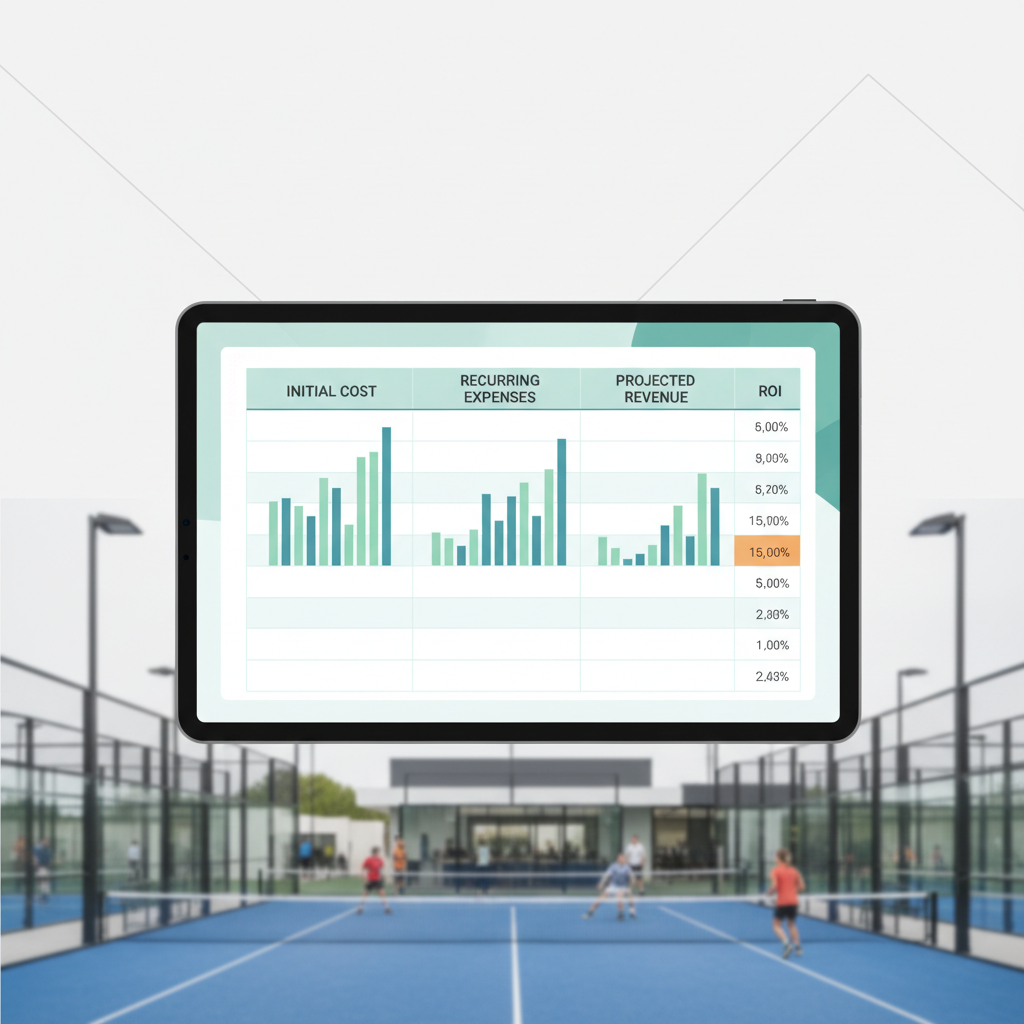

What ROI Can Facility Owners Expect?

Well-managed paddel courts generate $30,000-$60,000 annual revenue through hourly rentals, memberships, and programming, achieving 18-36 month payback periods on $50,000-$75,000 investments. Revenue optimization requires dynamic pricing based on peak/off-peak demand, integrated booking systems minimizing vacancy, and value-added services (coaching, tournaments, equipment retail) that extend customer lifetime value beyond basic court access.

Revenue Generation Models

Here’s the deal: multiple revenue streams compound returns dramatically.

Hourly court rental forms the foundation. Premium locations command $30-$60 per hour during peak times (evenings and weekends), with off-peak rates of $15-$30. A single court operating 10 hours daily at 60% average occupancy generates $65,000-$130,000 gross annual revenue. Multiple courts enable group bookings and tournament hosting, capturing premium pricing for exclusive access.

Membership models provide predictable recurring revenue. Monthly unlimited-play memberships priced at $80-$150 per person attract serious players who value predictable costs and guaranteed availability. Family or couples memberships at $120-$250 monthly capture demographic segments seeking shared activities. A 50-member base generates $48,000-$90,000 annually with minimal vacancy management overhead.

Ancillary revenue includes coaching ($40-$80 per hour private lessons), equipment sales (rackets, balls, bags), beverage service, and facility rental for private events. These streams add 15-25% incremental revenue above court access fees. Tournament entry fees ($50-$200 per team) combined with spectator admissions and vendor partnerships generate concentrated revenue spikes several times annually.

Operating Cost Structures

Think about it: understanding costs reveals true profitability.

Direct operating costs include utilities ($2,000-$5,000 annually for lighting and minimal facilities), maintenance ($2,000-$4,000), insurance ($3,000-$8,000 depending on coverage limits and claims history), and property taxes or lease payments (highly variable). Staff costs—if employing court managers or front desk personnel—range from minimal (volunteer/owner-operated) to $30,000-$60,000 annually for part-time staff.

Marketing and customer acquisition costs vary with competitive intensity. Established clubs with existing member bases might spend $2,000-$5,000 annually on promotional activities. New facilities in competitive markets might invest $10,000-$20,000 building initial awareness through digital marketing, community events, and promotional free-play periods.

The total operating expense typically ranges $15,000-$45,000 annually for single-court facilities, leaving $15,000-$85,000 net operating income before debt service or owner compensation. Multiple courts benefit from economies of scale—shared marketing, consolidated management, bulk purchasing—improving margins as facility scale increases.

Market Positioning Strategies

Look: premium positioning supports premium pricing.

High-end facilities differentiate through superior amenities: pristine maintenance, professional-grade lighting, climate-controlled lounges, equipment rentals, coaching staff, and member events. This positioning supports pricing 30-50% above competitors while attracting affluent demographics less price-sensitive and more focused on experience quality.

Budget-conscious positioning maximizes utilization through aggressive pricing and flexible booking policies. While per-hour rates might be 20-30% below premium competitors, higher occupancy rates (70-80% versus 50-60%) generate comparable absolute revenue. This model succeeds in emerging markets where paddel adoption is growing but hasn’t yet achieved mainstream penetration.

Tournament and league hosting generates concentrated revenue and builds community. Regional tournaments attract 50-200+ participants over weekend events, generating $5,000-$25,000 revenue episodes while creating promotional opportunities and establishing facility reputation. Regular leagues (weekly matches over 8-12 week seasons) drive consistent utilization and foster member loyalty through social connections.

Key Takeaway: Courts achieving 60%+ occupancy rates with integrated membership programs and value-added services consistently deliver 20-30% annual ROI, repaying initial investment within 3-5 years and generating substantial positive cash flow thereafter—making paddel courts one of the most attractive sports facility investments currently available.

| Revenue Stream | Unit Price | Annual Volume | Revenue Contribution |

|---|---|---|---|

| Peak Hourly Rental | $40-$60 | 1,200-1,800 hours | $48,000-$108,000 |

| Off-Peak Rental | $20-$30 | 800-1,200 hours | $16,000-$36,000 |

| Memberships | $100/month | 40-80 members | $48,000-$96,000 |

| Lessons & Coaching | $50/hour | 300-600 hours | $15,000-$30,000 |

| Total Revenue | — | — | $127,000-$270,000 |

Professional facility management guidance from experienced operators—contact us—accelerates revenue optimization and membership growth.

FAQ

Can I use regular tennis court lighting for a paddel court?

No, standard tennis lighting won’t meet paddel-specific requirements. Paddel courts demand 500-800 lux uniform illumination across the entire playing surface, with minimal glare for players. Tennis lighting typically provides 300-500 lux with different distribution patterns optimized for larger court dimensions, creating dark zones and excessive shadows when applied to paddel’s smaller footprint and enclosed structure.

What’s the difference between outdoor and indoor paddel courts?

Outdoor paddel courts expose materials to weather extremes—UV radiation, rain, temperature fluctuations—requiring UV-stabilized turf, weather-resistant steel coatings, and drainage systems. Indoor courts eliminate these environmental factors, extending material lifespan 30-50% while enabling year-round play regardless of conditions. However, indoor installations require building shells costing $150,000-$400,000 beyond court construction, plus HVAC systems maintaining comfortable temperatures and preventing condensation on glass walls.

How long does artificial turf last on a paddel court?

Premium artificial turf survives 8-12 years under normal usage (20-40 playing hours weekly) before requiring replacement. High-traffic commercial facilities might see 6-8 year lifespans, while lightly-used residential courts can extend 12-15 years. Lifespan depends critically on maintenance quality—regular grooming, infill top-ups, and cleaning extend usable life, while neglect accelerates fiber breakdown and backing deterioration requiring premature replacement.

Can paddel courts be relocated after installation?

Modular court systems support relocation, though the process isn’t trivial. Steel frames disassemble into component sections, glass panels remove intact (if handled carefully), and turf rolls up for transport. However, foundation work becomes site-specific sunk costs, and reassembly requires recertifying structural integrity and dimensional accuracy. Budget 40-60% of original installation cost for relocation—making it feasible for temporary venues or facilities closing but rarely economical for permanent installations.

What makes panoramic courts more expensive than standard designs?

Panoramic courts require 35-45% more glass area eliminating rear metal mesh sections, plus heavier glass panels (12mm versus 10mm) supporting structural loads without intermediate posts. Engineering complexity increases achieving structural stability from corner-post-only mounting rather than distributed support every 3 meters. The visual premium—unobstructed sightlines enhancing spectator experience—justifies 20-30% cost premium at tournament venues and luxury facilities where the aesthetic differentiates your offering from competitors.

Transform Your Vision Into Reality

Building a paddel court represents more than constructing a sports facility—you’re creating a community gathering space, revenue-generating asset, and lifestyle enhancement that serves players for decades. The difference between success and expensive regret lives in understanding that every decision—from foundation depth to glass specifications—either supports or undermines long-term performance.

Professional guidance matters. Working with experienced manufacturers who’ve installed thousands of courts globally eliminates the learning curve that costs first-time builders 15-30% in rework and specification errors. These partnerships provide access to proven designs, material sourcing, installation expertise, and ongoing support that transforms complex projects into predictable successes.

Your next step is clear: contact us today for a comprehensive site evaluation and customized proposal addressing your specific requirements, timeline, and budget. We’ll assess your property, navigate permitting requirements, specify optimal materials for your climate and usage patterns, and deliver a turnkey court ready to generate revenue and member satisfaction from day one.

SuperbPadel stands as your partner in excellence—combining factory-direct manufacturing with proven installation methodologies and post-completion support. Our vision extends beyond selling courts to building long-term relationships where your success becomes our success, your members’ satisfaction validates our craftsmanship, and your facility serves as a testament to what professional-grade paddel construction delivers.

Don’t settle for compromised specifications or inexperienced contractors—invest wisely in infrastructure that performs flawlessly for 20+ years, maximizes return on investment, and positions your facility as the premier paddel destination in your market.