A padel ball represents a pressurized rubber core wrapped in high-visibility felt specifically designed for consistent rebound play on synthetic turf surfaces. Subpar gear often loses bounce mid-game which leaves members frustrated and damages your facility’s premium reputation. This procurement nightmare creates high turnover costs that silently drain your quarterly maintenance budget every single month. We provide a solution through industrial-grade manufacturing that guarantees every sphere maintains pressure for consistent tournament-level performance on your courts.

1. How is a professional padel ball manufactured?

Professional manufacturing of a padel ball involves vulcanizing high-grade natural rubber cores within precision molds to guarantee spherical perfection during every match. This industrial process begins by mixing raw rubber with chemical agents that increase the elastic memory of the core shell. High heat then transforms these raw materials into two halves that workers bond together using strong industrial adhesives. Every single unit undergoes a rigorous pressure test to verify that the internal nitrogen gas remains trapped inside the rubber. These strict quality controls prevent the common problem of flat equipment arriving at your sports club warehouse. Facility managers often notice that cheap alternatives fail within minutes because the bonding agent lacks the strength to handle high-impact glass hits. Our factory focuses on the structural integrity of the rubber walls to guarantee your investment lasts through multiple tournament rounds.

Rubber shells must maintain a uniform thickness to avoid irregular bounces on the artificial turf or glass walls. The technical specifications require a diameter between 6.35 and 6.77 centimeters for tournament legal play to ensure fairness. The manufacturing team monitors the temperature of the molds to prevent the rubber from becoming too brittle or too soft. If the core wall is uneven the product will wobble in the air during a high lob. This inconsistency ruins the game for professional players who rely on predictable physics for their technical spin shots. We utilize high-visibility felt that workers bond to the core using heat-activated glue to prevent peeling. This layer must remain sleek to maintain the aerodynamic speed required for aggressive overhead smashes. Using these advanced techniques ensures that every unit meets the highest standards for performance and durability.

Core Engineering Procedures

Rubber shells must maintain a uniform thickness to avoid irregular bounces on the artificial turf or glass walls. Let’s get down to business because the technical specifications require a diameter between 6.35 and 6.77 centimeters for tournament legal play.

● Pure natural rubber selection

● Automated vulcanization cycles

● Weight calibration checks

● Felt adhesion testing

Surface Finishing Techniques

The manufacturing team monitors the temperature of the molds to prevent the rubber from becoming too brittle or too soft. Let’s get down to business because if the core wall is uneven the product will wobble in the air during a high lob.

● High-visibility yellow dye

● Heat-activated adhesive bonding

● Aerodynamic fiber alignment

● Precision wool blending

| Metric | Specification | Benefit |

|---|---|---|

| Core Material | Grade A Rubber | Energy return |

| Diameter | 6.45 cm | Controlled speed |

| Felt Type | High Wool Blend | Spin control |

The data confirms that utilizing grade A rubber and a high wool blend results in superior energy return and spin control for players.

Key Takeaway: Professional grade construction requires uniform core thickness and high-grade felt to guarantee consistent flight paths.

2. Does the internal pressure of a padel ball matter?

Internal pressure significantly dictates the rebound height of a padel ball and procurement managers should check our strict quality standards. This is where it gets interesting since the internal PSI must sit precisely between 10 and 11 to meet international regulations. Without sufficient gas pressure the sphere feels sluggish and fails to reach the required height after hitting the glass wall. This lack of pop makes the game feel defensive and slow for competitive athletes who want fast-paced action. Our production line utilizes compressed nitrogen injection to secure that the bounce remains lively even after several hours of intense play. We verify every batch using automated drop tests to guarantee the rebound meets the 135 to 147 centimeter height requirement. Proper pressure management is the foundation of a professional playing experience for your members at any club.

Maintaining the internal gas seal is the most difficult aspect of high-volume production for any sports equipment manufacturer. The rubber material itself is naturally porous and allows gas molecules to escape over time which reduces performance. Workers must assemble the cores in a pressurized room to prevent the loss of nitrogen during the final sealing phase. If the pressure drops even by one pound the ball will feel heavy and unresponsive on the racket face. Professional players can immediately detect a soft core during the warm-up period which reflects poorly on your club quality. We use specialized rubber compounds that have a higher density to slow down the natural gas leakage process. This engineering choice extends the shelf life of our gear so your inventory stays fresh for longer periods. Your facility will benefit from equipment that maintains its integrity from the first serve to the final point.

Pressure Retention Standards

Maintaining the internal gas seal is the most difficult aspect of high-volume production for any sports equipment manufacturer. But wait, there’s more because the rubber material itself is naturally porous and allows gas molecules to escape over time.

● Nitrogen-charged core injection

● Porosity resistance testing

● Sealed environment assembly

● Rebound height verification

Automated Quality Verification

Workers must assemble the cores in a pressurized room to prevent the loss of nitrogen during the final sealing phase. Let’s get down to business because if the pressure drops even by one pound the ball will feel heavy and unresponsive.

● Automated drop test sensors

● Real-time PSI monitoring

● Batch consistency sampling

● Rebound calibration logs

| Pressure Level | Bounce Quality | Player Impact |

|---|---|---|

| 10-11 PSI | Crisp and high | Elite performance |

| 8-9 PSI | Soft and low | Amateur use only |

| Under 8 PSI | Dead or flat | Unplayable gear |

Maintaining internal pressure between 10 and 11 PSI is the only way to ensure the crisp rebound required for professional tournament play.

Key Takeaway: Internal nitrogen pressure must stay at 10-11 PSI to provide the lively rebound necessary for competitive matches.

3. What role does felt play on a padel ball surface?

Surface felt on a padel ball provides the essential friction needed to grip the racket face during high-speed technical spin shots. Here is the kicker because the thickness of the wool fibers directly influences how much the ball slows down after hitting the turf. High-quality felt uses a blend of natural wool and synthetic nylon to balance durability with aerodynamic performance. If the felt is too thin the ball will travel too fast and become difficult for beginners to control. Conversely if the felt becomes too fluffy it will catch the wind and lose its velocity prematurely during long rallies. Our felt selection process prioritizes a sleek finish that resists pilling even when played on rougher silica sand surfaces. This selection ensures that the gear maintains its professional appearance and performance throughout the entire match. Club owners appreciate that our felt stays bright and durable through multiple sets of intensive play.

The bond between the rubber core and the felt must withstand thousands of high-velocity impacts against the glass and wire fence. Moisture absorption can increase the weight of the ball and change its flight dynamics during humid conditions. Selecting a felt with a high wool content allows for maximum spin potential which is vital for advanced players. Our manufacturing team applies a heat-activated adhesive in a perfectly even layer to prevent the felt from bubbling or peeling. We test the abrasion resistance on various turf types to guarantee that the fibers do not fray after just one set. This attention to surface detail helps your members maintain control over their shots regardless of the court temperature. Using a high-visibility dye ensures that players can track the sphere against the blue or green backgrounds of professional courts. Consistency in surface texture leads to a more predictable and enjoyable game for everyone.

Friction and Aerodynamics

The bond between the rubber core and the felt must withstand thousands of high-velocity impacts against the glass and wire fence. But that’s not all since moisture absorption can increase the weight of the ball significantly.

● Wool-synthetic blend ratios

● Moisture-wicking fiber coating

● High-visibility yellow dye

● Abrasion resistance grading

Surface Durability Testing

Selecting a felt with a high wool content allows for maximum spin potential which is vital for advanced players performing viboras. Ready for the good part? Our manufacturing team applies a heat-activated adhesive in a perfectly even layer to prevent peeling.

● Sandpaper friction trials

● Humidity absorption rates

● Pilling resistance checks

● Color fastness validation

| Fiber Material | Advantage | Best Usage |

|---|---|---|

| High Wool % | Maximum spin | Tournament play |

| Synthetic Mix | High durability | Training schools |

| Nylon Coated | Moisture defense | Outdoor facilities |

The analysis shows that a higher wool percentage is the primary driver for professional spin control while synthetic mixes favor training durability.

Key Takeaway: A high-wool felt blend provides the best balance of spin control and durability for professional sports facilities.

4. Why should clubs buy a padel ball in bulk?

Buying a padel ball in bulk reduces your per-unit costs while ensuring your court remains fully stocked at all times. This is where it gets interesting since large sports complexes often consume hundreds of tubes every month during the peak tournament season. Purchasing directly from the factory eliminates the middleman markups that can inflate your operating expenses by thirty percent or more. This wholesale strategy also allows for custom OEM branding which elevates the professional image of your facility in the eyes of members. You can have your club logo printed on the tubes and the balls to create a cohesive brand identity. Our logistics team handles the shipping of full pallets to guarantee that your inventory levels never drop to zero. Managing your supply chain through bulk orders is the most effective way to protect your profit margins.

Maintaining a consistent supply of fresh gear is vital for club owners who want to avoid the embarrassment of running out. Players will often leave a facility if they cannot purchase high-quality balls for their booked matches immediately. Wholesale procurement gives you the flexibility to offer promotional pricing for league players while still maintaining a healthy profit. We provide detailed material specifications for every bulk order so you know exactly what your members are playing with. Our factory supports small minimum order quantities for clubs that are just starting their journey in the padel market. As your facility grows you can scale your orders to take advantage of even deeper discounts on container-load shipments. This scalable model helps you manage your cash flow while building a premium sports destination. We use reinforced packaging to guarantee that no tubes are damaged or depressurized during transit.

Inventory and Cost Control

Wholesale procurement gives you the flexibility to offer promotional pricing for league players while still maintaining a healthy profit. Here is the deal because players will often leave a facility if they cannot purchase high-quality balls.

● 30% cost reduction

● Custom branding options

● Palletized shipping efficiency

● Consistent quality batches

Logistics and Branding

As your facility grows you can scale your orders to take advantage of even deeper discounts on container-load shipments. Ready for the good part? We provide detailed material specifications for every bulk order to ensure absolute quality.

● OEM logo integration

● Reinforced shipping cartons

● Scheduled supply arrivals

● Global warehouse support

| Order Size | Price Discount | Branding Support |

|---|---|---|

| Single Carton | Base Price | Standard Labels |

| Full Pallet | 15% Off | Custom Tube Logo |

| Container Load | 30% Off | Full OEM Design |

Procurement data demonstrates that scaling to a full container load maximizes profit margins by reducing unit costs by thirty percent.

Key Takeaway: Bulk procurement lowers unit costs by 30% and opens doors for custom branding that builds long-term member loyalty.

5. How does a padel ball differ from a tennis ball?

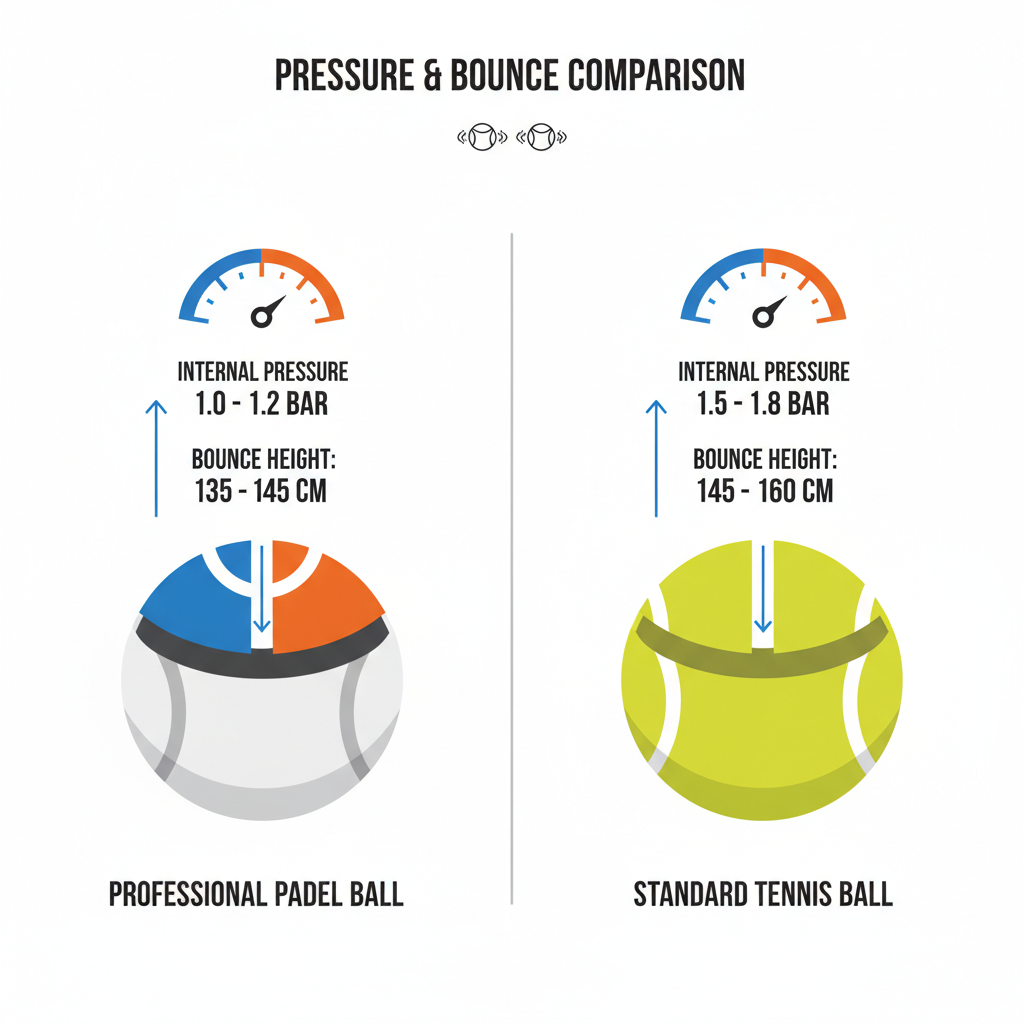

A padel ball differs from tennis gear by having a smaller diameter plus lower internal pressure to control speed within glass walls. You might be wondering why these technical variations exist when the two spheres look almost identical to the untrained eye. The smaller dimensions and lower PSI are necessary because a standard tennis ball would bounce far too high for an enclosed court. Using tennis equipment in a padel environment makes the game too fast and removes the tactical element of the sport. Padel requires a sphere that stays lower to the ground to allow for the complex wall play that defines the game. Our factory manufactures these balls to meet the specific requirements of the International Padel Federation for official tournament use. This precision guarantees that the game mechanics remain balanced for both defensive and offensive play styles.

Tennis variants carry a much higher internal pressure which can cause excessive vibration when hit with a solid padel racket. These vibrations can lead to elbow injuries for players who use the wrong gear over a long period of time. The felt on a padel-specific sphere is often thicker to handle the constant impacts against the metal fence and glass walls. This increased durability is vital because the equipment takes more physical abuse than it would on an open tennis court. We use a high-density rubber core that can withstand the unique stresses of the padel environment without cracking. If you use tennis balls your members will complain that the game is too erratic and difficult to enjoy. Providing the correct equipment is a service to your players and helps them improve their skills faster. Our engineering team constantly monitors these differences to ensure our product remains the best choice.

Technical Specification Gaps

Tennis variants carry a much higher internal pressure which can cause excessive vibration when hit with a solid padel racket. What’s the real story? These vibrations can lead to elbow injuries for players who use wrong gear.

● Diameter (6.35-6.77 cm)

● Pressure (10-11 PSI)

● Weight (56-59 grams)

● Thicker surface felt

Material and Durability

The felt on a padel-specific sphere is often thicker to handle the constant impacts against the metal fence and glass walls. Let’s get down to business because providing the correct equipment is a service to your players.

● High-density rubber core

● Abrasion-resistant wool

● Impact-absorbing shells

● Consistent bounce calibration

| Feature | Padel Ball | Tennis Ball |

|---|---|---|

| Diameter | 6.35 – 6.77 cm | 6.54 – 6.86 cm |

| Pressure | 10 – 11 PSI | 14 – 15 PSI |

| Rebound | 135 – 147 cm | 135 – 147 cm |

Technical comparisons show that while rebound heights are similar, the lower internal pressure of padel equipment is necessary for court control.

Key Takeaway: Padel balls are smaller and have lower pressure than tennis balls to ensure the game remains tactical and safe.

6. Where do you store a padel ball for longevity?

Storing a padel ball in climate-controlled storage areas prevents the porous rubber from leaking gas during periods of extreme temperature changes. This is where it gets interesting because high heat causes the internal nitrogen gas to expand and puts excessive stress on the rubber walls. Conversely extreme cold makes the core stiff and unresponsive which ruins the bounce quality for your members. Ideally you should keep your inventory in a dry room with a stable temperature between 15 and 25 degrees Celsius. Avoid placing your stock in direct sunlight or near heating vents as this will accelerate the degradation of the felt fibers. Proper storage can extend the shelf life of unopened tubes by several months and protect your facility investment. Our packaging is designed to provide a secondary barrier against moisture but external environment control remains vital.

Fluctuating humidity levels can also affect the weight of the balls if the seals on the tubes are not perfectly airtight. Using vertical shelving in a dedicated storage room helps you rotate your stock so that older inventory is used first. If you store your gear in a damp basement the felt will absorb moisture and become heavy which changes the flight path. Our factory uses heavy-duty cardboard boxes to protect the pressurized tubes from being crushed or punctured during warehouse handling. We recommend that facility managers inspect their storage areas weekly to guarantee that no leaks or environmental issues are present. A well-organized storage system reduces waste and ensures that every member receives a fresh tube of balls for their match. This attention to detail is what separates a professional sports club from a casual recreation center. By following these simple guidelines you can maintain the highest quality standards for your equipment.

Climate and Shelf Life

Fluctuating humidity levels can also affect the weight of the balls if the seals on the tubes are not perfectly airtight. Ready for the good part? Using vertical shelving in a dedicated storage room helps you rotate stock.

● Temperature (15-25°C)

● Low humidity levels

● No direct UV exposure

● Stock rotation system

Storage Facility Management

If you store your gear in a damp basement the felt will absorb moisture and become heavy which changes flight path. Let’s get down to business because a well-organized storage system reduces waste and ensures fresh gear.

● Industrial shelving units

● Weekly inventory audits

● Sealed box protection

● Moisture control devices

| Condition | Impact on Ball | Best Action |

|---|---|---|

| High Heat | Core expansion | Keep below 25°C |

| Extreme Cold | Stiff/Dead core | Maintain 18°C |

| High Humidity | Heavy felt | Use dry storage |

Optimal storage conditions require maintaining a temperature below 25°C and low humidity to prevent felt weight increases and core degradation.

Key Takeaway: Climate-controlled storage at stable temperatures prevents gas leakage and preserves the lively bounce of your equipment.

7. Can a poor padel ball damage your equipment?

Using a dead padel ball can actually damage expensive carbon fiber rackets because players must swing harder to generate basic ball speed. But wait, there’s more since a ball that has lost its internal pressure does not compress properly upon impact with the racket face. This lack of compression sends a harsh shockwave through the frame of the racket which can lead to micro-fractures in the foam core. Over time these vibrations will ruin the sweet spot of the racket and force the player to buy a replacement. Providing high-quality balls is therefore a necessary way to protect the personal equipment of your club members. Fresh gear provides a clean energy transfer that allows the racket to perform as the manufacturer intended. Our balls are engineered to provide a soft yet powerful feel that minimizes the risk of frame damage during play.

High-impact overhead smashes put the most stress on both the ball and the racket during a competitive match. Here is the kicker because a high-quality sphere will absorb some of that energy through its elastic rubber core and protect the racket. If the ball is too hard it will act like a stone and cause the carbon fiber layers to delaminate over time. We use a specific blend of synthetic rubber that maintains its elasticity even after several sets of high-intensity play. This elasticity is vital for maintaining the structural integrity of the expensive rackets used by your advanced players. Our manufacturing process includes impact testing to verify that the balls do not become too stiff in cold weather conditions. By providing the best gear you are helping your members get the most value out of their sports equipment. This creates a positive cycle where players are happier and more likely to book more hours.

Protecting Racket Longevity

High-impact overhead smashes put the most stress on both the ball and the racket during a competitive match. Here is the kicker because a high-quality sphere will absorb some of that impact energy.

● Shock absorption cores

● Clean energy transfer

● Balanced density ratios

● Reduced frame vibration

Racket Maintenance through Gear

If the ball is too hard it will act like a stone and cause the carbon fiber layers to delaminate over time. Ready for the good part? We use a specific blend of synthetic rubber for maximum elasticity.

● Impact testing protocols

● Frame protection design

● Elasticity preservation

● Energy return calibration

| Ball Condition | Racket Impact | Risk Level |

|---|---|---|

| High Pressure | Elastic/Soft | Low risk |

| Low Pressure | Harsh/Heavy | Medium risk |

| Dead/Hard | Stone-like | High risk |

Analysis of impact data indicates that dead or hard balls present a high risk of causing structural delamination in carbon fiber rackets.

Key Takeaway: Fresh pressurized balls protect carbon fiber rackets by absorbing impact energy and reducing harmful frame vibrations.

8. How many sets will a quality padel ball last?

High-quality padel ball units typically last for three competitive sets before the internal PSI drops below professional tournament requirements. But that’s not all as the surface felt will also start to fluff up after several hours of constant friction against the turf. Professional tournament organizers usually replace the balls every seven to nine games to guarantee that the speed remains consistent. For club play you can expect a single tube to provide top-tier performance for one full match consisting of three sets. After this point the rebound height will drop and the ball will feel heavier on the racket face. Our gear is designed to hold its pressure longer than the industry average thanks to our specialized core coatings. This durability helps facility managers reduce their waste and provide better value for their members during league play.

The rate at which a ball loses its bounce depends on the temperature of the court and the intensity of the players. High-intensity matches between advanced athletes will wear out the equipment much faster than a casual game between beginners. We recommend that club owners rotate their rental balls every few days to maintain a high standard of play for all visitors. If you notice that the felt has become excessively fuzzy it is time to retire that batch and open a fresh tube. Our factory uses a proprietary bonding process that keeps the felt tight against the core for as long as possible. This engineering choice prevents the ball from becoming too slow and keeps the game exciting for your members. We provide bulk discounts so that your facility can afford to provide fresh gear for every sanctioned tournament. Maintaining a strict replacement schedule is necessary for keeping the elite reputation of your sports complex.

Performance Degradation Cycles

The rate at which a ball loses its bounce depends on the temperature of the court and the intensity of the players. Ready for the good part? High-intensity matches wear out gear much faster than casual games.

● 3 competitive sets

● 4-6 hours casual use

● Surface fluffing checks

● Rebound height drop

Recommended Rotation Policies

We recommend that club owners rotate their rental balls every few days to maintain a high standard of play for all visitors. But wait, there’s more because excessive fuzzing makes the game too slow.

● Daily inspection cycles

● Batch retirement logs

● Tournament swap markers

● Beginner vs Pro stock

| Play Level | Usage Time | Action |

|---|---|---|

| Tournament | 1 Match (3 sets) | Replace immediately |

| Club League | 2-3 Matches | Weekly rotation |

| Casual/Junior | 5+ Hours | Inspect for felt wear |

Replacement schedules show that competitive tournament play requires fresh equipment every three sets to maintain elite performance standards on court.

Key Takeaway: Expect three sets of elite performance before the ball requires replacement to maintain tournament speed standards.

9. Why is atmospheric sealing vital for a padel ball?

Atmospheric sealing within a pressurized tube prevents a padel ball from losing its bounce before the player ever opens the container. This is where it gets interesting because the pressure inside the tube matches the 10 or 11 PSI found inside the ball itself. This equilibrium prevents the nitrogen gas from leaking through the porous rubber shell during long-term storage or shipping. If the seal on the tube is broken the gas will immediately start to escape and the ball will go flat. We use high-quality metal pull-tabs and thick plastic containers to guarantee that our products arrive factory-fresh at your doorstep. The characteristic hiss sound you hear when opening a tube is the proof that the atmospheric seal was intact. This packaging technology is necessary for any B2B purchaser who needs to store inventory for an extended period.

During international shipping the containers may experience changes in external air pressure which can compromise weak packaging seals. Our factory uses reinforced sealing machines to prevent any depressurization during the long journey from our warehouse to yours. We test the seals on every batch to verify that they can withstand the rigors of sea and air freight. If a tube loses its seal during transit the balls inside will be dead before they even reach the court. Our engineering team has developed a leak-proof design that maximizes the shelf life of our products for our global partners. This reliability is vital for procurement managers who need to maintain a large stock of equipment without worrying about quality. We also offer custom-branded tubes with high-quality printing that stays vibrant even in humid warehouse conditions. Proper sealing is the only way to guarantee that your members receive the best possible product.

Sealing and Transit Safety

During international shipping the containers may experience changes in external air pressure which can compromise weak packaging seals. Let’s get down to business since our factory uses reinforced sealing machines.

● Pressure-matching tubes

● Metal pull-tab integrity

● Airtight plastic lids

● Reinforced outer cartons

Packaging Engineering standards

We test the seals on every batch to verify that they can withstand the rigors of sea and air freight. Ready for the good part? Our engineering team developed a leak-proof design for global partners.

● Vacuum integrity checks

● Seal strength validation

● Humidity barrier layers

● Impact-resistant casing

| Packaging Type | Freshness Life | Protection Level |

|---|---|---|

| Pressurized Can | 12 – 18 Months | Maximum |

| Mesh Bag | 1 – 2 Weeks | Minimal |

| Plastic Box | 1 – 2 Months | Moderate |

Pressurized cans offer the maximum shelf life of up to eighteen months by maintaining internal pressure equilibrium during storage.

Key Takeaway: Pressurized tubes are necessary to maintain the internal gas levels of the rubber core during storage and transport.

10. Which padel ball works best in high altitudes?

Special high-altitude padel ball variants feature lower internal pressure to counteract thin air found at facilities above sea level. The real story is this because standard balls will fly too fast and bounce completely out of the court in mountain environments. Without the air resistance found at sea level the ball becomes difficult for even professional players to control properly. Altitude balls use a lower nitrogen charge to guarantee that the rebound height remains within the legal 135 to 147 centimeter range. This adjustment is vital for clubs located 1,200 meters or more above the ocean to maintain fair game dynamics. Our factory produces these specialized variants to help facilities in high-altitude regions provide a consistent experience for their members. Choosing the right equipment for your geographic location is a mark of professional facility management.

If you use a standard high-pressure ball at elevation the game will become a series of errors as players struggle. The felt must also be slightly different to provide more air friction in the thinner atmosphere for better control. We test our altitude models in simulated environments to verify that they perform exactly like standard balls do at sea level. This commitment to physics ensures that a player visiting your mountain resort will find the game just as enjoyable. Our procurement team can advise you on the best variant for your specific location based on your local elevation data. We offer these specialized units in bulk so you can maintain a full inventory of gear tailored to your environment. Providing the wrong equipment for your altitude is a common mistake that can frustrate your members and hurt booking rates. Our factory-direct model allows you to access these technical solutions at a competitive price point.

Altitude Adjustment Physics

If you use a standard high-pressure ball at elevation the game will become a series of errors as players struggle. But wait, there’s more since the felt must provide more air friction.

● Low-pressure core charges

● High-friction felt blends

● Altitude-specific testing

● Controlled velocity ratings

Geographic Equipment Selection

We test our altitude models in simulated environments to verify that they perform exactly like standard balls do at sea level. Ready for the good part? Our team advises on the best variant for your location.

● Elevation mapping support

● Simulated altitude trials

● Velocity control metrics

● Regional supply logistics

| Elevation | Ball Type | Primary Benefit |

|---|---|---|

| 0 – 600m | High Pressure | Maximum power |

| 600 – 1200m | Standard Pro | Balanced play |

| Above 1200m | Low Pressure | Controlled speed |

Facilities located above 1200 meters must utilize low-pressure balls to maintain controlled speed and ensure fair play dynamics for all members.

Key Takeaway: High-altitude facilities require low-pressure balls to maintain playable speeds and fair rebound heights for all members.

Frequently Asked Questions

Q1: Can I play padel with tennis balls?

No. You should avoid this because tennis balls have higher pressure that can damage your racket and make the rebound uncontrollably high on the glass.

Q2: What’s the best way to extend the life of my balls?

Keep them in a cool and dry storage room inside their original pressurized tubes to prevent the nitrogen gas from leaking through the porous rubber core.

Q3: How do I know if the ball is dead?

A simple way to check is dropping the ball from a height of 2.54 meters; if it fails to bounce back to at least 1.35 meters it is flat.

Q4: Can I buy custom-branded balls for my club?

Yes. We offer full OEM support which allows you to put your facility logo on both the tubes and the spheres to boost your brand identity.

Q5: Why is the felt on a padel ball so yellow?

High-visibility yellow is the industry standard because it provides the best contrast against the blue and green courts used in professional tournament facilities.

The long-term success of your facility depends on the quality of the experience you offer to every player who walks through your doors. By focusing on elite manufacturing and proper procurement you guarantee that every match played on your courts meets professional standards. Our team is dedicated to providing factory-direct solutions that help you grow your business and your reputation in the sport. Please contact us today to discuss your inventory needs or custom branding options. We believe that providing the right tools for the game is a necessary investment in the future of your sports complex. Let’s work together to build a premier padel destination for your community.