Facility owners often face a daunting challenge when planning a new sports venue: ensuring every specification meets official regulations while maximizing player satisfaction. Failing to adhere to strict construction standards creates liability risks, results in rapid equipment deterioration, and drives away serious players who demand professional-grade conditions. This comprehensive guide provides the exact roadmap you need for designing high-performance padel fields, covering everything from historical foundations and precise dimensions to advanced material selection and safety protocols.

Table of Contents

- How did the history of padel fields begin?

- What are the official dimensions of padel fields?

- How do padel fields differ from tennis courts?

- What surfaces are best for padel fields?

- How are padel fields designs evolving?

- How do professionals build modern padel fields?

- What trends are shaping the future of padel fields?

- What materials determine the quality of padel fields?

- How should you maintain high-quality padel fields?

- Why are safety standards critical for padel fields?

- FAQ

How did the history of padel fields begin?

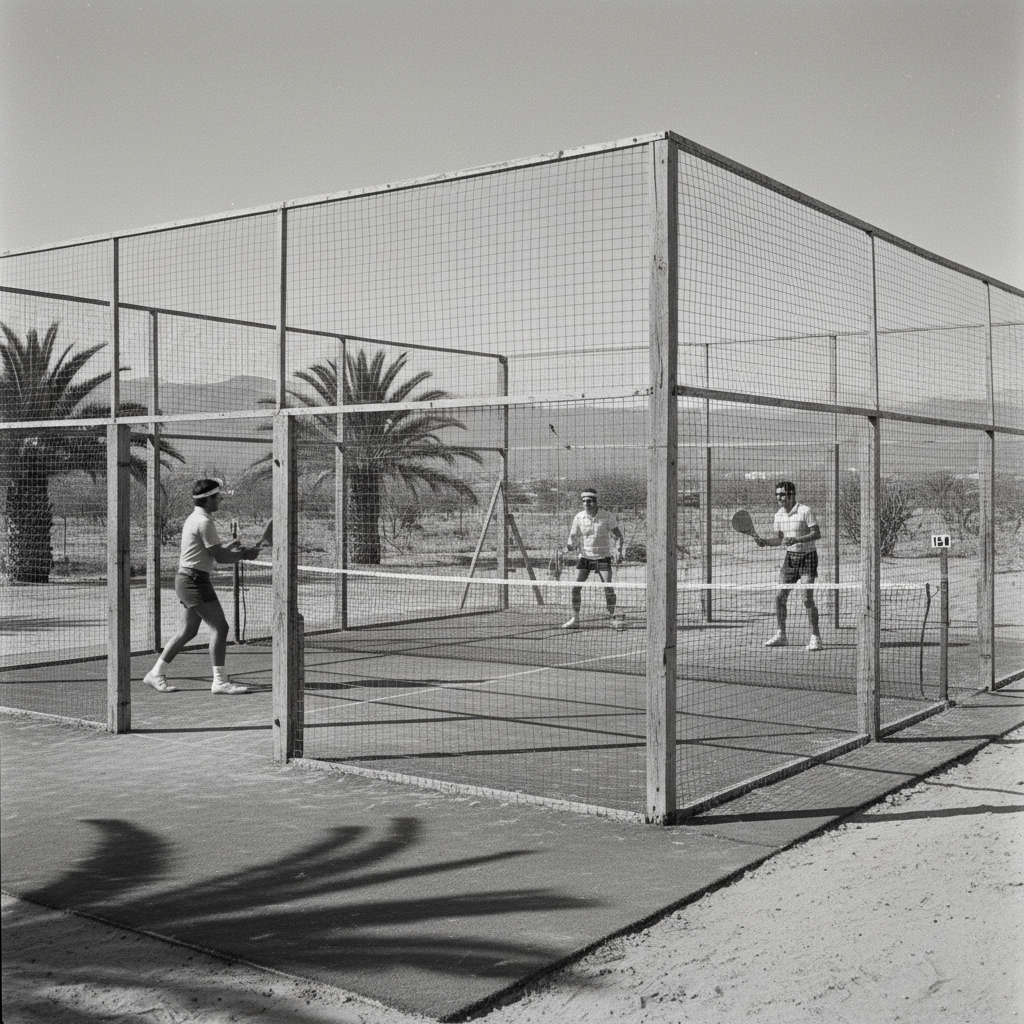

Enrique Corcuera invented the sport in Acapulco, Mexico, during 1969 because his home lacked sufficient space for a traditional tennis court. He utilized existing walls on his property, enclosing a 20×10 meter area which became the prototype for all future courts. This adaptation allowed players to use the walls strategically, creating a faster and more dynamic game than traditional tennis. Alfonso de Hohenlohe later brought this concept back home after visiting Mexico in 1974, constructing the first European courts in Marbella, Spain. You might be wondering how such a simple backyard modification sparked a global phenomenon. It succeeded by prioritizing social interaction and accessibility over pure athleticism.

Understanding these origins helps operators appreciate why standard padel fields retain specific characteristics like enclosed walls and compact dimensions. The sport expanded rapidly through Argentina and Spain during the 1980s and 1990s, eventually leading to the formation of the International Padel Federation. Modern construction still honors Corcuera’s original vision while incorporating advanced materials like tempered glass and synthetic turf. Here’s the deal: knowing the history ensures you respect the game’s fundamental mechanics during the design phase.

| Era | Key Milestone |

|---|---|

| 1969 | Invention by Enrique Corcuera in Acapulco, Mexico. |

| 1974 | Introduction into Spain by Alfonso de Hohenlohe. |

| 1990s | Establishment of the International Padel Federation. |

| 2020s | Rapid global expansion and modernization of facilities. |

What are the official dimensions of padel fields?

Strict adherence regarding the standard 10x20m padel field measurements remains non-negotiable for any facility aiming for professional certification. The playing area must form a rectangle exactly 20 meters long and 10 meters wide, with a net dividing the court into two equal halves. Indoor facilities require a minimum free height of 6 meters across the entire surface, although 8 meters is highly recommended so players can perform lobs without obstruction. But here’s the kicker: even a variance of a few centimeters can disqualify a court from hosting official tournaments.

Designers must also account for the service lines, located exactly 6.95 meters from the net, and a central service line dividing the back area into two equal zones. All lines must measure 5 centimeters in width, typically painted white or black for maximum contrast against the turf. Lighting systems often require mounting at least 6 meters high outside the vertical projection of the court walls. It’s important to note that these strict metrics ensure fair play and consistency across all competitive venues worldwide.

| Dimension | Requirement |

|---|---|

| Length | 20 meters |

| Width | 10 meters |

| Min Height | 6 meters (Indoor) |

| Net Height | 0.88m (center) – 0.92m (sides) |

How do padel fields differ from tennis courts?

Enclosed padel fields distinguish themselves from tennis courts primarily through their use of walls as an active part of gameplay. Tennis courts occupy a much larger footprint, measuring roughly 23.77 meters by 10.97 meters, and require significant run-off space around the perimeter. Padel utilizes a compact 10×20 meter footprint enclosed by glass and mesh, allowing the ball to remain in play even after bouncing off the back or side walls. This structural difference creates a faster-paced game emphasizing strategy and reflexes over sheer power.

Surface materials also vary significantly between the two sports, with tennis employing clay, grass, or hard acrylic surfaces. Padel almost exclusively uses artificial turf filled with silica sand, which provides specific grip and bounce characteristics suited for the enclosed environment. What’s the real story? Facility owners often assume they can simply convert a tennis court into a padel court, but the structural loads and foundation requirements for the glass walls make this complex. Padel encourages doubles play almost exclusively, whereas tennis frequently features singles matches.

| Feature | Padel Fields | Tennis Courts |

|---|---|---|

| Size | 20m x 10m | 23.77m x 10.97m |

| Enclosure | Walls (Glass/Mesh) | Open |

| Surface | Artificial Turf | Hard/Clay/Grass |

| Gameplay | Doubles (Standard) | Singles/Doubles |

What surfaces are best for padel fields?

Selecting the correct padel-specific artificial turf defines player comfort and ball performance more than any other factor. Manufacturers typically offer three main fiber types: monofilament, fibrillated, and textured, each serving different facility needs. Monofilament fibers consist of individual strands that stand upright, offering superior durability and a slower game pace preferred by professionals. Fibrillated turf features a mesh-like structure that holds sand infill securely, making it an excellent choice for clubs prioritizing low maintenance.

Textured or “curly” fibers represent the latest innovation, providing optimal grip and shock absorption while requiring less sand maintenance. Silica sand infill plays a mandatory role in all systems, stabilizing the fibers and ensuring consistent ball bounce throughout the court. Ready for the good part? Choosing the right turf can extend your court’s lifespan by years while reducing daily upkeep costs. Facility managers must balance performance needs with their maintenance budget when selecting between these options.

| Surface Type | Characteristics | Best Use |

|---|---|---|

| Monofilament | Durable, upright fibers | Professional/High-traffic |

| Fibrillated | Mesh-like, holds sand well | Clubs/Entry-level |

| Textured | Curled fibers, premium grip | Elite Tournaments |

How are padel fields designs evolving?

Modern design has shifted dramatically towards panoramic padel fields that remove rear structural pillars to offer spectators unobstructed views. This evolution transforms the court into a visual centerpiece, utilizing 12mm tempered glass and minimal steel fixings for a sleek, high-end appearance. Facilities now frequently integrate social zones directly adjacent to the courts, recognizing that padel operates as a highly social activity. You might be wondering if these aesthetic upgrades impact durability, but advances in glass engineering maintain strict safety standards.

Color customization has moved beyond traditional green, with blue becoming the industry standard for television visibility, and black or red turf emerging in premium clubs. Lighting design has also advanced, with linear LED systems replacing bulky floodlights to reduce glare and improve broadcast quality. These design shifts aim to create an immersive experience that attracts premium clientele and supports tournament hosting. Here’s the deal: investing in panoramic designs often yields higher court rental rates.

| Trend | Benefit |

|---|---|

| Panoramic Glass | Unobstructed visibility for spectators. |

| Colored Turf | Visual appeal and branding alignment. |

| Social Zones | Encourages community and longer dwell time. |

How do professionals build modern padel fields?

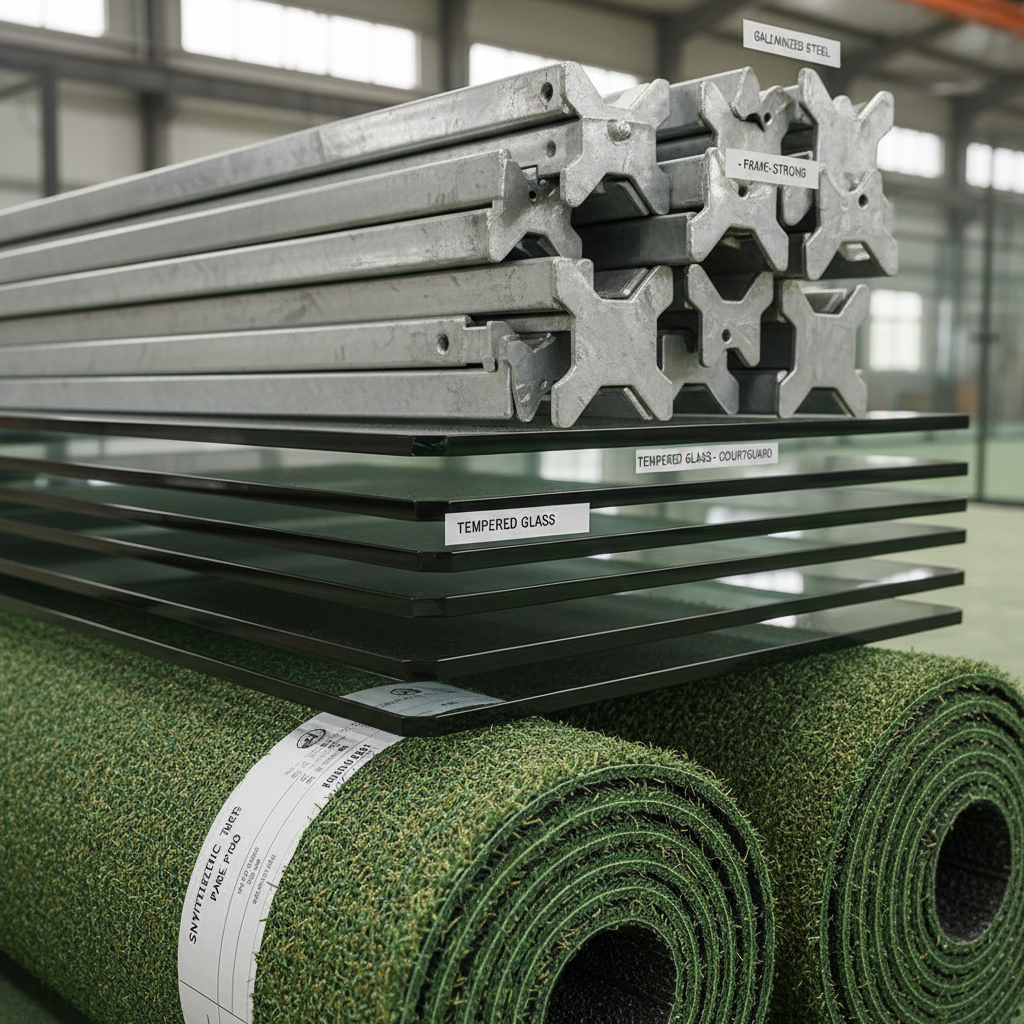

Constructing a durable steel frame assembly begins with a perfectly leveled reinforced concrete perimeter beam to support the heavy glass loads. The installation process demands precision; even millimeter deviations in the foundation can cause glass panels to shatter under stress. Builders typically install the galvanized steel structure first, ensuring all modules align perfectly before securing the 10mm or 12mm tempered glass panels. This is where it gets interesting: proper drainage slope planning prevents water accumulation that can ruin the artificial turf.

Outdoor installations require robust rust protection, often involving hot-dip galvanization followed by electrostatic powder coating. The final phase involves laying the artificial turf and distributing silica sand evenly using specialized brushing machines. Professionals verify the structural integrity of every bolt and anchor point to guarantee player safety during high-impact wall collisions. Cutting corners on the foundation or steel quality inevitably leads to costly structural failures.

| Phase | Critical Action |

|---|---|

| Foundation | Level concrete beam with drainage slope. |

| Structure | Galvanized steel installation. |

| Enclosure | 10-12mm tempered glass mounting. |

| Surfacing | Turf laying and sand distribution. |

What trends are shaping the future of padel fields?

Technology integration is revolutionizing modern court systems, transforming standard facilities into smart venues. New courts feature automated access controls where players unlock doors via mobile apps, while intelligent lighting systems adjust brightness based on occupancy. Cameras installed around the court frame allow for instant replay and live streaming, enhancing the player experience and enabling coaching analytics. What’s the catch? These high-tech features require robust electrical planning during the initial construction phase.

Sustainability also drives current trends, with manufacturers developing recyclable turf and using solar-powered lighting solutions. Some clubs now install roofs with integrated photovoltaic panels to offset energy costs, creating eco-friendly sports environments. The push for “smart” venues extends to booking platforms that integrate seamlessly with court hardware, reducing staffing needs for facility operators. Adopting these technologies positions a club as a market leader.

| Innovation | Benefit |

|---|---|

| Smart Access | Automated entry and lighting control. |

| Video Analytics | Player performance tracking and streaming. |

| Eco-Design | Solar integration and recyclable materials. |

What materials determine the quality of padel fields?

Investing in premium court designs requires understanding which materials drive longevity and performance. The glass quality stands as the single most critical safety factor; 12mm tempered glass is recommended for panoramic courts to withstand player impact without shattering. Steel profiles must undergo hot-dip galvanization to resist corrosion, particularly in humid or coastal environments where rust attacks quickly. But here’s the kicker: cheaper untreated steel might save upfront costs but will structurally fail within a few years.

Lighting components also impact the budget significantly, with high-end LED systems providing the necessary 300-500 lux for competition without blinding players. The choice between standard and premium artificial turf affects both the installation cost and the frequency of replacement. Facility owners must weigh these initial material expenses against long-term maintenance savings and liability reductions.

| Material | Impact |

|---|---|

| Glass Type | High (Safety & Visibility) |

| Steel Treatment | High (Durability & Rust Proofing) |

| Lighting | Medium (Energy Efficiency) |

| Turf Quality | Medium (Playability & Lifespan) |

How should you maintain high-quality padel fields?

Effective turf maintenance extends the life of a court significantly and ensures consistent playing conditions. Facility staff must redistribute silica sand infill every two weeks using a specialized brush, preventing compaction and uneven bounce. Neglecting this simple task leads to accelerated fiber wear and a slippery playing surface that risks player injury. You might be wondering how often glass needs attention; cleaning panels weekly is essential for visibility and aesthetics.

Structural checks should occur monthly, focusing on tightening loose bolts and inspecting glass anchors for signs of stress. Outdoor courts require additional care to remove organic debris like leaves or moss that can block drainage and damage the turf backing. Implementing a strict maintenance schedule protects the investment and keeps the facility tournament-ready year-round.

| Task | Frequency |

|---|---|

| Brushing Turf | Bi-weekly |

| Cleaning Glass | Weekly |

| Check Structure | Monthly |

| Deep Clean | Annually |

Why are safety standards critical for padel fields?

Compliance with structural integrity protocols is the only defense against severe accidents and liability claims. The International Padel Federation mandates that all glass walls must meet EN 12150 standards for tempered safety glass, ensuring that if breakage occurs, the glass crumbles into harmless cubes rather than jagged shards. Lighting systems must deliver uniform illumination of at least 300 lux to prevent dangerous shadows that could obscure the fast-moving ball. Here’s the deal: skipping safety certifications puts your entire business at risk.

Fencing must be flush with the glass panels to prevent irregular bounces or injury from protruding edges. Additionally, ample run-off zones outside the court doors are required to allow players to exit safely during intense points. Regular safety audits verify that wear and tear haven’t compromised these critical protections.

| Component | Safety Standard |

|---|---|

| Glass | 10-12mm Tempered (EN 12150) |

| Lighting | Min 300 Lux (Uniformity) |

| Fencing | Flush mounting, no sharp edges |

Conclusion

Designing high-quality padel fields requires a delicate balance of engineering precision, material quality, and adherence to international standards. From the foundational concrete beam to the final layer of silica sand, every component plays a vital role in player safety and commercial success. By focusing on robust structural integrity and modern amenities, you create a facility that stands out in a competitive market.

Don’t compromise on quality. Whether you are upgrading an existing club or building a new venue, partnering with experts ensures your courts stand the test of time. For factory-direct solutions and professional guidance, visit SuperbPadel to start your project on the right track.

FAQ

Q1: Can I build padel fields in my backyard?

Yes, provided you have a level space of at least 11×21 meters to accommodate the court and necessary run-off areas. You will need a concrete foundation and must check local zoning laws regarding structure height and noise regulations before construction begins.

Q2: What is the minimum ceiling height for indoor padel fields?

The absolute minimum clear height required is 6 meters across the entire court surface. However, a height of 8 meters or more is strongly recommended for commercial clubs to allow players to execute lobs effectively without hitting the ceiling.

Q3: How long does it take to construct padel fields?

Installation of the court structure itself typically takes 3-5 days per court once the foundation is ready. However, the entire process, including site preparation, concrete curing (which takes about 21-28 days), and permitting, can take 6-8 weeks.

Q4: Do padel fields require planning permission?

In most jurisdictions, yes. Padel courts are considered permanent structures due to their concrete foundations and 4-meter high walls. You will likely need permits for the structure, fencing, and lighting, especially for outdoor installations near residential areas.

Q5: What is the lifespan of artificial turf on padel fields?

With proper maintenance, high-quality artificial turf typically lasts between 4 to 6 years, depending on the intensity of use. Regular brushing and sand redistribution are key factors in maximizing the longevity of the playing surface.