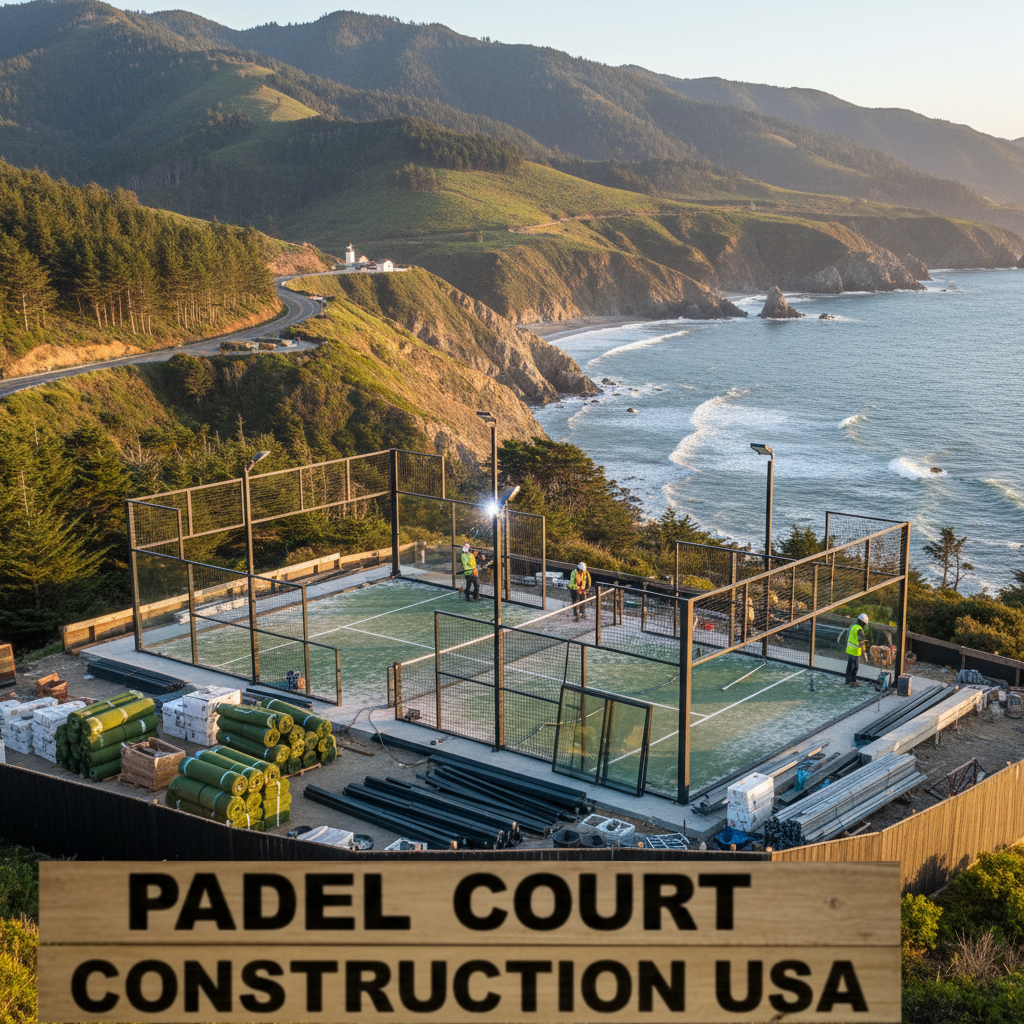

Padel court construction usa is the specialized process of engineering and installing a 20×10 meter sports facility designed for high-performance play and structural longevity. You are likely standing on the threshold of a massive commercial opportunity as the racket sports market shifts, yet you may feel overwhelmed by the technical complexities of American building codes and soil requirements. Without a precise engineering roadmap, your significant capital investment could easily vanish into site preparation delays or structural glass failures that compromise both safety and your long-term return on investment. Basically, this definitive technical guide provides the exact blueprint you need to navigate padel court construction usa with professional precision, ensuring your facility becomes a durable, high-revenue asset.

What is padel court construction usa exactly?

Padel court construction usa is the highly specialized synthesis of civil engineering and architectural assembly required to produce a professional-grade 200-square-meter playing environment within the North American regulatory framework. This process demands a deep understanding of how to integrate 12mm tempered safety glass with a zinc-coated steel superstructure that can withstand the specific seismic and wind-load pressures of various US regions. You must prioritize the creation of a perfectly level reinforced concrete slab, as even a minor deviation will fundamentally ruin the ball’s rebound consistency and the overall integrity of the glass enclosure. Here is the deal: building a court in the US isn’t just about assembly; it’s about meeting rigorous local engineering stamps that guarantee the facility remains standing for decades.

What makes these courts unique for the American market?

You might be wondering why you cannot simply import a standard European kit and expect it to survive the high humidity of Florida or the heavy snow loads of the Northeast without modifications.

- Reinforced zinc-coated steel frames prevent the rapid oxidation commonly found in coastal American environments.

- Specialized 12mm tempered safety glass is mandatory to meet the strict liability and safety standards of US commercial properties.

- Advanced monofilament turf systems are engineered to provide maximum joint protection for a wide range of athletic demographics.

- Customized stadium LED lighting must be calibrated to provide 500-750 lux while complying with local dark-sky ordinances.

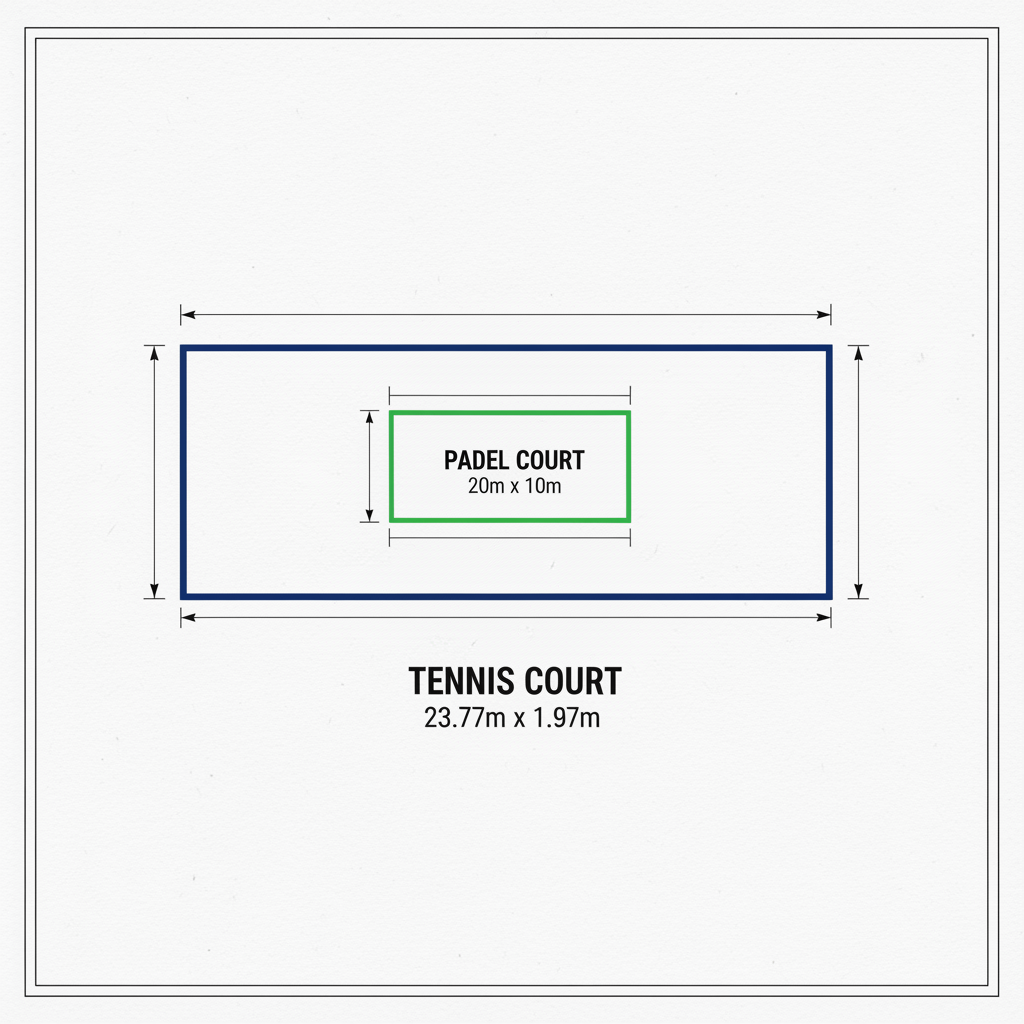

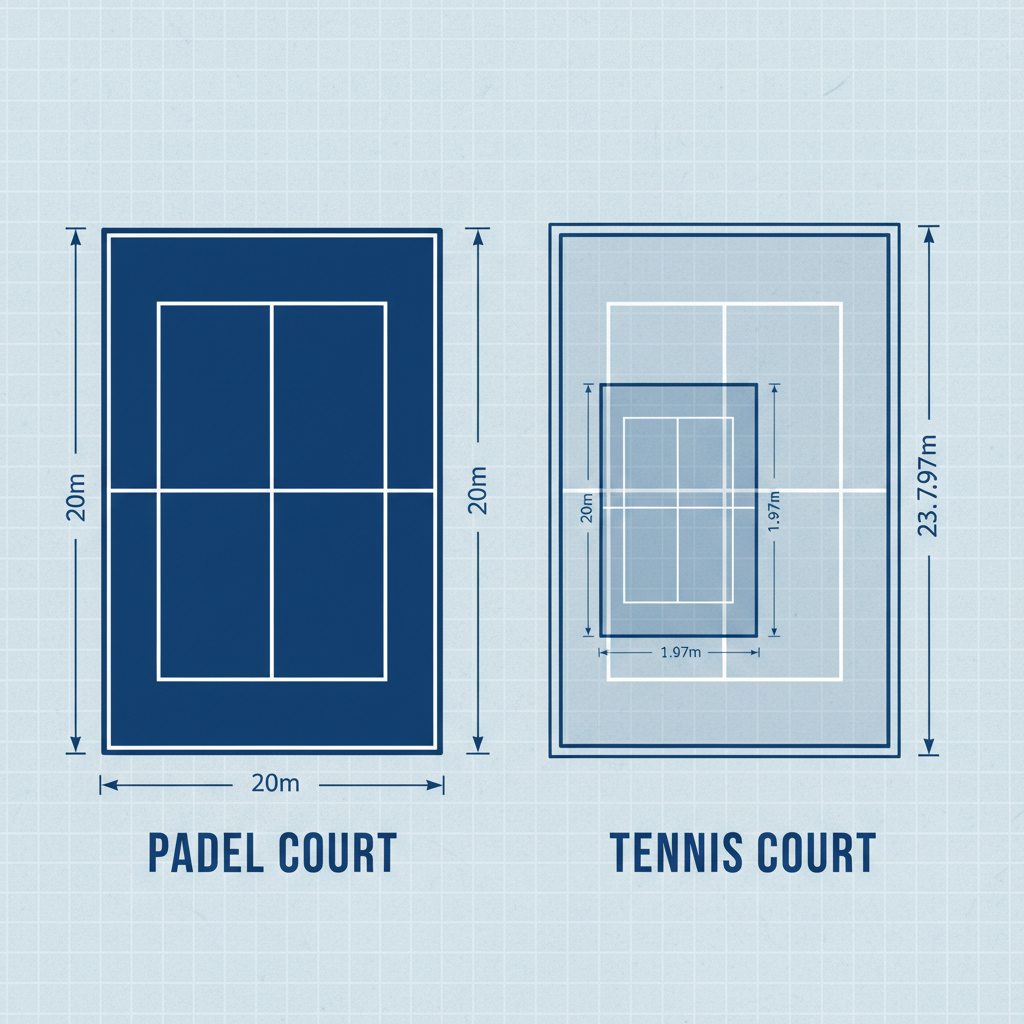

How do dimensions affect the structural engineering requirements?

But here is the kicker: the precision of your 20×10 meter footprint determines the entire success of the glass installation because the panels have zero tolerance for foundation shifts.

- The standard 200-square-meter playing area must be surrounded by a minimum one-meter safety buffer for maintenance access and spectator safety.

- Vertical clearance of at least six to eight meters is required to accommodate the high-lob shots that define professional padel gameplay.

- Foundation thickness must exceed 15cm of reinforced concrete to prevent the heavy glass walls from settling unevenly over time.

- Structural bolt patterns for the pillars must be laser-aligned to ensure the electro-welded mesh and glass panels fit seamlessly without stress points.

Key Takeaway: Precision engineering of the 20x10m area is the non-negotiable foundation for every successful professional build in the United States.

| Component | Metric Size | US Imperial Equivalent | Requirement |

|---|---|---|---|

| Playing Length | 20 Meters | 65.6 Feet | High Precision |

| Playing Width | 10 Meters | 32.8 Feet | High Precision |

| Glass Height | 3 Meters | 9.8 Feet | Tempered Safety |

| Vertical Clear | 6-8 Meters | 19.7-26.2 Feet | Unobstructed |

The technical transition from metric standards to US imperial measurements is the first critical step in ensuring your local contractors execute the grading and slab pouring with absolute accuracy.

Why is padel court construction usa growing so fast?

Padel court construction usa is accelerating at an unprecedented rate because the sport offers a significantly higher player-per-square-foot density than any other racket sport, effectively tripling the potential revenue of traditional tennis facilities. You are seeing a fundamental shift where luxury developers and health club owners are replacing underutilized tennis courts with multiple Standard Padel Court installations to maximize their land’s financial yield. This trend is driven by the fact that you can accommodate four active players in just 200 square meters, creating a high-energy social environment that keeps members engaged longer and spending more. Think about it: in an era of skyrocketing urban real estate costs, the efficiency of this sport makes it the most logical choice for modern sports facility development.

What market trends drive US padel court demand?

The bottom line is this: modern athletes are seeking social, fast-paced experiences that are easier to learn than tennis but offer a similar level of competitive intensity.

- Integration into high-end residential wellness centers significantly increases the market value of luxury apartment and condo developments.

- Conversion of underutilized big-box retail space into indoor padel clubs provides a second life for struggling commercial real estate.

- Country clubs are adding padel to their portfolios to attract a younger, more active demographic that prioritizes social networking over tradition.

- Public-private partnerships are beginning to fund padel installations in municipal parks to meet the surging demand for accessible racket sports.

How does padel compare to tennis for club ROI?

Ready for the good part? You can actually fit three regulation padel courts in the exact same footprint required for one standard doubles tennis court, including its runoff areas.

- Higher hourly turnover rates are achieved through 90-minute match windows that keep the court schedule moving and profitable.

- Maintenance costs are drastically lower for synthetic turf than for natural grass or specialized clay tennis surfaces.

- Smaller land parcels allow for the development of high-density clubs in urban centers where tennis courts would be physically impossible to build.

- Ancillary revenue from pro shop sales, racket rentals, and social food and beverage programming scales more efficiently with more players onsite.

Key Takeaway: High player density and small physical footprints make this the most lucrative racket sport investment available for US developers today.

| Metric | Padel Court | Tennis Court | Revenue Multiplier |

|---|---|---|---|

| Area (sqm) | 200 | 600+ | 3.0x Space Efficiency |

| Player Count | 4 | 2-4 | 2.0x Capacity |

| Maintenance | Low | High | Reduced Overhead |

| Build Time | 8-12 Weeks | 12-16 Weeks | Faster To Market |

The superior space-to-revenue ratio of padel installations allows commercial operators to achieve a faster break-even point than traditional tennis or multi-sport facilities.

How do you start padel court construction usa?

Padel court construction usa begins with a rigorous site analysis and geotechnical soil report to determine the load-bearing capacity and drainage requirements for the heavy glass and steel superstructure. You must ensure the ground is properly compacted and treated for expansive clay before pouring the reinforced concrete slab, as any ground movement will inevitably lead to catastrophic glass panel breakage. Mapping underground utilities and ensuring compliance with local environmental runoff regulations is a critical first step that avoids expensive redesigns later in the project lifecycle. Basically, if your foundation is not engineered with a 10-year outlook, the rest of the court’s premium components are essentially being built on borrowed time.

What site requirements are mandatory for US builds?

Wait, there is more: you must account for the specific wind-load requirements of your local county, which often dictate the thickness of the steel pillars and glass.

- Reinforced concrete bases must have a minimum thickness of 15cm with a high-strength PSI rating to support the localized weight of the corners.

- Precise laser-leveling is required to ensure the final surface has no more than a 1% slope for outdoor drainage or 0% for indoor builds.

- Underground electrical conduits must be pre-planned to hide the wiring for stadium lighting and automatic gate systems for a clean aesthetic.

- A one-meter safety buffer around the perimeter is essential for both structural stability and to allow for proper drainage channels.

How do you choose between indoor and outdoor facility types?

It gets better: climate-controlled indoor facilities allow you to generate revenue 365 days a year, regardless of winter snow or summer heat waves that deter outdoor play.

- Indoor facilities require a minimum ceiling height of 8 meters to allow for unencumbered high-performance play and lob shots.

- Outdoor courts must utilize UV-resistant paint and hot-dip galvanized steel to prevent the rapid degradation caused by direct sun and rain.

- Acoustic planning is vital for both types, but especially for outdoor builds near residential zones to mitigate the sound of ball impacts.

- Proper drainage systems for outdoor slabs must move water away from the court quickly to prevent the silica sand from clumping and ruining the turf.

Key Takeaway: Thorough site preparation and selecting the correct environment for your climate are the two most critical factors in court longevity.

| Site Factor | Indoor Requirement | Outdoor Requirement | Impact on Longevity |

|---|---|---|---|

| Slope | 0% (Perfectly Flat) | 1% (Drainage Grade) | Ball Bounce Accuracy |

| Ceiling | 8m Minimum | Unrestricted | Playability Grade |

| Material | Standard Powder Coat | Hot-Dip Galvanized | Rust Prevention |

| Lighting | High-Bay LEDs | Wind-Resistant Poles | Operational Hours |

Selecting the right environment for your court depends on local weather patterns and your business model’s need for year-round operational consistency.

What are the main padel court construction usa steps?

Padel court construction usa involves a precise chronological sequence that transitions from heavy earthmoving and concrete work to the delicate installation of high-tension nets and monofilament turf. You must strictly adhere to a 21-day concrete curing schedule before attempting to bolt down the structural steel pillars, as premature anchoring can lead to micro-fissures in the foundation. This sequential approach ensures that every component, from the glass panels to the silica sand infill, is supported by a stable and fully hardened base. Here is the kicker: rushing any of these phases is the primary reason why amateur builds fail within the first two years of heavy commercial operation.

How is the concrete foundation and slab prepared?

You might be wondering if you can simply use an existing asphalt parking lot as a shortcut for your court’s foundation, but the answer is a definitive no.

- Excavation involves removing all topsoil and organic material to reach stable sub-soil that can be compacted to professional engineering standards.

- A heavy-duty vapor barrier is installed beneath the rebar grid to prevent rising damp from ruining the synthetic turf adhesives.

- The concrete must be finished with a specialized power-trowel technique to create a smooth, non-slip surface for the turf to bond with.

- Expansion joints must be strategically placed outside the playing area to prevent the slab from cracking under the court’s glass walls.

What is the process for glass and steel assembly?

This is where it gets interesting: the alignment of the steel pillars must be accurate to within millimeters to ensure the heavy glass panels do not experience torsional stress.

- Structural pillars are bolted down using high-strength chemical anchors that provide permanent stability against heavy wind loads and player impacts.

- 12mm tempered safety glass panels are lifted into place using specialized vacuum suction equipment and secured with industrial-grade rubber gaskets.

- Electro-welded mesh panels are integrated into the frame to provide the specific ball rebound characteristics required for professional-level doubles play.

- Industrial silicone is applied to all joints to seal the enclosure and absorb the vibrations generated during high-velocity matches.

Key Takeaway: Adhering to a strict timeline for concrete curing and frame assembly is the only way to prevent expensive structural failure later.

| Construction Phase | Critical Task | Duration | Success Metric |

|---|---|---|---|

| Earthworks | Soil Compaction | 5-7 Days | 95% Proctored |

| Foundation | Concrete Pour | 2-3 Days | Level within 1% |

| Curing | Hydration | 21 Days | Full PSI Strength |

| Structure | Glass/Steel | 5-7 Days | Perfect Alignment |

Following this sequential blueprint ensures your facility meets the highest standards of safety and professional playability from the very first match.

Which padel court construction usa materials are best?

Padel court construction usa quality is fundamentally defined by the grade of the materials used in the build, specifically the thickness of the tempered glass and the density of the synthetic turf. You should never settle for 10mm glass in a commercial environment, as the 12mm standard provides significantly better durability and a more consistent ball bounce for high-level competitive play. Choosing hot-dip galvanized steel for your frame is the only way to ensure the structure survives the corrosive American climate without requiring a full repaint within three years. Keep this in mind: the materials you choose today will dictate whether your court is a high-performing asset or a maintenance-heavy liability five years from now.

What is the real story? Cheap budget glass often contains microscopic impurities that cause spontaneous shattering when exposed to the intense temperature swings of the American South.

- Heat-soak tested tempered glass is mandatory for commercial installations to minimize the risk of sudden breakage and potential legal liability.

- 12mm glass thickness provides the specific weight and rigidity needed to ensure the ball rebounds exactly as it would on a professional world-tour court.

- Polished edges and countersunk holes for the mounting hardware prevent localized stress points that can lead to cracks during extreme weather events.

- High-clarity panoramic panels provide an unobstructed view for spectators, which is essential for televised tournaments and high-end club aesthetics.

What turf options provide the best long-term durability?

So, basically, the color of your turf isn’t just an aesthetic choice; blue has become the international standard because it provides the highest visual contrast for the ball.

- Textured monofilament fibers are superior to fibrillated options because they retain the silica sand infill better and resist matting under heavy foot traffic.

- High Dtex ratings indicate a denser fiber that can withstand the intense friction and lateral movements inherent in padel’s fast-paced gameplay.

- UV-stabilized coatings are essential to prevent the vibrant blue or green color from fading into a dull grey after just one summer of direct exposure.

- Specialized backing allows for rapid vertical drainage, ensuring the court is dry and playable within minutes after a heavy rain shower.

Key Takeaway: Investing in 12mm tempered glass and high-Dtex monofilament turf is the only way to reduce long-term maintenance and replacement costs.

| Material | Professional Standard | Budget Alternative | Long-term Impact |

|---|---|---|---|

| Glass | 12mm Heat-Soak | 10mm Standard | Safety & Rebound |

| Frame | Hot-Dip Galv | Spray Painted | Rust & Maintenance |

| Turf | Monofilament | Fibrillated | Player Comfort |

| Lighting | 750 Lux LED | 300 Lux Halogen | Playability Hours |

Selecting professional-grade materials from the outset guarantees that your facility remains a premium destination for serious athletes and recreational players alike.

Is padel court construction usa profitable for clubs?

Padel court construction usa represents a transformative revenue opportunity for fitness entrepreneurs because it targets a high-spending demographic that values both athletic competition and social networking. You can expect a much faster return on investment than traditional fitness facilities by utilizing a Panoramic Padel Court to attract premium membership tiers and corporate tournament sponsorships. The ability to host four players on a single small court means your revenue per square foot is far higher than that of a yoga studio, weight room, or tennis court. Here is the deal: a well-managed padel club in a prime US location can often see its initial construction costs paid off within 18 to 24 months of operation.

How many players can a single court handle daily?

But wait, there is more: the social nature of padel means that players are more likely to participate in high-margin activities like clinics, social mixers, and leagues.

- Up to forty-eight players can cycle through a single court during a standard twelve-hour operating window with 90-minute match times.

- Youth academy programs and senior clinics allow you to fill off-peak morning and afternoon hours that would otherwise remain empty.

- Corporate teambuilding events and weekend tournaments provide high-impact revenue spikes that can exceed several thousand dollars in a single day.

- Social leagues encourage recurring weekly participation, creating a stable and predictable base of rental income for your facility.

What are the primary revenue streams for US courts?

The kicker is… padel players are notoriously high spenders on equipment, fashion, and post-match social experiences compared to other athletes.

- Direct hourly court rentals are your primary income source, with rates in the US ranging from $40 to $120 per hour depending on the market.

- A well-stocked pro shop selling high-end rackets, specialized footwear, and apparel can contribute an additional 15-20% to your gross monthly revenue.

- Private coaching and group clinics allow you to monetize the expertise of your staff while improving the overall skill level and engagement of your members.

- Corporate glass panel sponsorships offer high-margin advertising opportunities for local luxury brands, car dealerships, and real estate firms.

Key Takeaway: Superior player turnover and multiple ancillary revenue streams from pro shops and coaching make padel a robust B2B investment.

| Revenue Stream | Daily Est. (High Use) | Monthly Potential | Profit Margin |

|---|---|---|---|

| Court Rental | $600 | $18,000 | Very High |

| Pro Shop | $150 | $4,500 | Moderate |

| Coaching | $250 | $7,500 | High |

| Sponsorship | $50 | $1,500 | Extremely High |

The diverse revenue potential of a padel facility allows for multiple paths to profitability, making it a highly resilient business model in the US sports market.

What does padel court construction usa cost involve?

Padel court construction usa pricing is influenced by a complex mix of international freight logistics, local civil engineering costs, and the specific material grade chosen for the installation. You must account for the fact that shipping heavy, fragile components like 12mm tempered glass across the United States can often represent a significant percentage of your total project budget. Understanding the cost calculation for your specific region is vital to ensuring you have adequate capital for site preparation, permitting, and final structural assembly. Let’s be honest: cutting corners on the initial budget usually leads to much higher maintenance expenses and structural repairs within the first few years of operation.

How do shipping and logistics impact your total pricing?

You might be wondering why the cost of a court can vary so significantly between a coastal city and a landlocked Midwest location, and it all comes down to freight.

- Specialized crating for panoramic glass panels is required to prevent expensive breakage during the trans-continental shipping and local delivery process.

- Heavy machinery rentals for the initial excavation, grading, and concrete pouring must be carefully scheduled to avoid expensive daily downtime.

- Import duties and customs clearance for high-end European components can add unexpected line items to your initial financial projections.

- Last-mile delivery to residential or tight urban sites often requires smaller, specialized equipment that increases the overall labor cost of the install.

What are the long-term maintenance expenses you should expect?

Wait, there is more: your initial investment must be protected through a proactive maintenance schedule that keeps the court in professional playing condition.

- Monthly redistribution of the silica sand infill is mandatory to prevent the turf fibers from crushing and ensure a consistent ball bounce.

- Periodic inspections and tightening of the structural fasteners in the steel frame prevent the glass panels from vibrating and potentially cracking.

- Annual deep cleaning of the synthetic turf and glass panels is required to maintain the premium aesthetic and safety standards of a high-end club.

- Replacing the high-tension net and its winding mechanism every 12 to 24 months ensures the court always feels brand new to your paying members.

Key Takeaway: Logistics and the reinforced concrete base represent the largest variable costs in any professional US racket sports construction project.

| Cost Category | Estimated Range | % of Total Budget | Variable Factor |

|---|---|---|---|

| Superstructure | $30k – $50k | 50% | Material Grade |

| Foundation/Slab | $15k – $25k | 25% | Soil Conditions |

| Freight/Install | $10k – $15k | 15% | Site Location |

| Permitting/Eng | $5k – $10k | 10% | Local Zoning |

Careful budget planning that includes a 10-15% contingency for site preparation is the best way to ensure your project reaches completion without financial stress.

How long does padel court construction usa take?

Padel court construction usa timelines generally span between 8 and 12 weeks from the moment you place your initial deposit to the grand opening match on your new facility. You must account for the non-negotiable three-week curing period for the concrete slab, which is essential to reaching the structural PSI required to support the Super Panoramic Padel Court architecture. Coordinating with local contractors for the grading and foundation work is often the most time-consuming phase, while the actual assembly of the glass and steel usually happens in under ten days. Here is the deal: any project that claims a faster timeline is likely compromising on the foundation’s structural integrity or the precision of the glass alignment.

What is the typical timeline from permit to play?

Think about it: the administrative side of your project, including zoning reviews and building permits, will often take longer than the physical construction process itself.

- Permit approval can take anywhere from 4 to 8 weeks depending on the complexity of your local municipality’s sports facility regulations.

- Site preparation and the initial concrete pour typically require 7 to 10 days of stable weather to ensure the slab sets correctly.

- The 21-day curing phase is the perfect time to finalize your marketing plan, hire coaching staff, and set up your online court booking system.

- Final assembly, including the steel frame, glass installation, turf laying, and stadium lighting, is a highly efficient process that takes roughly one week.

How do weather conditions cause delays in the US?

The kicker is… high humidity and rain are the natural enemies of a successful synthetic turf installation, as moisture prevents the adhesives from bonding to the concrete.

- Heavy wind events make the installation of large panoramic glass panels extremely dangerous and will immediately halt the assembly process for safety reasons.

- Freezing temperatures prevent the concrete from hydrating correctly, which can lead to structural weakness and surface scaling that ruins the final finish.

- Consistent rain during the excavation phase can turn your site into a mud pit, delaying the grading process and pushing back the entire project schedule.

- High humidity during the turf laying phase can lead to trapped moisture bubbles beneath the surface, which eventually cause the turf to peel away.

Key Takeaway: Administrative permits take significantly longer than the physical assembly; you should plan for a total three-month window.

| Milestone | Week Number | Phase | Critical Dependency |

|---|---|---|---|

| Permitting | 1 – 4 | Planning | Local Gov Speed |

| Foundation | 5 – 6 | Civil Work | Dry Weather |

| Curing | 7 – 9 | Structural | 21-Day Period |

| Assembly | 10 – 12 | Launch | Expert Crew |

Managing your expectations around the concrete curing phase is the best way to ensure your facility is built to a professional standard that lasts for decades.

Are padel court construction usa permits required?

Padel court construction usa requires a deep understanding of local building codes, as many US counties classify these 12-ton glass and steel facilities as permanent structures. You must ensure that your project adheres to strict zoning setbacks, noise ordinances, and environmental regulations regarding stormwater runoff from the large concrete slab. Failing to secure the correct electrical permits for your stadium lighting or ignoring drainage compliance can lead to expensive fines or even a full stop-work order on your project. So, basically, treating this as a simple “landscaping project” is a massive mistake that can put your entire capital investment at significant legal risk.

Which local zoning laws affect your sports court?

What is the real story? The “pop” sound of a padel ball impact is higher in decibels than a tennis match, making noise mitigation a primary concern for local zoning boards.

- Setback requirements mandate a specific distance between your court’s glass walls and the property lines of neighboring residential or commercial lots.

- Noise ordinance compliance may require you to install acoustic fencing or limit the hours of operation for your facility to maintain community harmony.

- Light pollution regulations often dictate the type of shielded LED fixtures you can use to prevent “light spill” into the night sky or adjacent properties.

- ADA accessibility laws require you to provide clear, paved pathways for players with physical disabilities to access the court and its amenities safely.

Ready for the good part? Proper environmental planning for drainage actually improves the lifespan of your court by preventing water from pooling and damaging the foundation.

- Stormwater management plans are often required for any new non-permeable surface like a 200-square-meter concrete slab to prevent local flooding.

- Erosion control measures must be in place during the excavation and grading phase to prevent silt from entering the municipal storm drain systems.

- Sustainable disposal of construction debris and soil is a mandatory requirement in many environmentally conscious US states and municipalities.

- Integrating bioswales or permeable perimeter materials can help you meet strict local runoff standards while enhancing the overall aesthetics of your site.

Key Takeaway: Engaging a local civil engineer to review zoning and drainage is a paramount step for achieving long-term legal and environmental compliance.

| Permit Category | Mandatory? | Complexity | Professional Needed |

|---|---|---|---|

| Zoning/Land Use | Yes | High | Civil Engineer |

| Building/Structural | Yes | Moderate | Architect/Engineer |

| Electrical | Yes | Moderate | Licensed Electrician |

| Drainage/Erosion | Yes | High | Environmental Consultant |

Navigating the permitting process with professional help ensures your facility is legally protected and ready for commercial operation without the threat of municipal intervention.

How to find a padel court construction usa expert?

Padel court construction usa expertise is a rare commodity in the North American market, making it essential for you to vet contractors based on their specific experience with glass-to-steel sports structures. You should look for a team that provides comprehensive Roofed Padel Court solutions and can demonstrate a successful portfolio of US-based commercial or residential installations. An expert contractor doesn’t just assemble a kit; they manage the entire engineering lifecycle, from soil compaction to the final calibration of the stadium lighting systems. Basically, hiring a general landscaping company to build a professional padel court is the fastest way to end up with a structural failure and a ruined investment.

What certifications should a padel contractor hold?

It gets better: an expert installer will have specialized training in handling 12mm panoramic glass, which is the most fragile and expensive component of your entire project.

- A General Contractor license in your specific state ensures the team is fully insured and adheres to all local labor and safety regulations.

- Manufacturer-certified installation training guarantees that the specific warranty requirements for the glass, turf, and steel are fully met during assembly.

- Comprehensive liability insurance covering structural glass failure and onsite accidents protects your capital investment from unexpected legal claims.

- A proven track record of building to high wind-load or seismic standards demonstrates the technical depth required for long-term facility durability.

How do you verify past successful projects?

The kicker is… you should always visit at least two existing sites built by your potential contractor to check for signs of frame oxidation, glass misalignment, or turf bubbling.

- Interview previous commercial clients to understand how the contractor managed unexpected soil issues or municipal permitting delays during the build process.

- Inspect the quality of the industrial silicone seals and the tensioning of the mesh panels to see how the court has held up under heavy daily use.

- Review the consistency of the ball bounce across the entire surface of an older installation to verify the contractor’s ability to level concrete slabs.

- A true expert will offer at least a 10-year structural warranty on the hot-dip galvanized frame, providing you with long-term peace of mind for your investment.

Key Takeaway: Prioritize contractors with an extensive portfolio of glass-based sports installations to avoid common rookie mistakes that ruin facility durability.

| Selection Criteria | Weighting | Why it Matters |

|---|---|---|

| Proven Portfolio | 40% | Demonstrates structural precision |

| Comprehensive Warranty | 30% | Protects your capital long-term |

| Local Licensing | 30% | Ensures legal and safety compliance |

Choosing a contractor with a specialized focus on padel is the single most important decision you will make in ensuring the commercial success of your new facility.

Conclusion

Building a world-class facility requires far more than just purchasing a court; it demands a deep technical mastery of structural engineering, local US logistics, and precise site preparation. By prioritizing high-grade 12mm glass, hot-dip galvanized steel, and monofilament turf, you ensure that your investment becomes a high-performance asset that delivers consistent revenue for decades. The rapid expansion of padel in the American market represents a fundamental opportunity for developers who understand the value of quality and safety in sports construction. Our vision is to empower American sports entrepreneurs with the technical expertise needed to build iconic facilities that define the future of racket sports. Contact us today to begin your journey toward owning a premier padel destination that will lead the market for years to come.

FAQ

Q1: Can I install a padel court on an existing tennis court?

Yes, but only if you reinforce the existing slab to handle the significant localized weight of the steel pillars and the 12-ton glass enclosure. You can typically fit three padel courts on the footprint of one standard tennis court, making it an excellent way to modernize your sports facility.

Q2: What is the best lighting system for commercial night play?

LED stadium lighting with a minimum output of 500-750 lux is the professional standard for ensuring no shadows fall on the glass or the court surface. You must ensure the fixtures are shielded to comply with local dark-sky ordinances and avoid light spill into neighboring residential properties.

Q3: How do I know if my soil is stable enough for a concrete slab?

You should always conduct a geotechnical soil report before breaking ground to identify expansive clay or unstable sub-soil that could cause foundation shifting. If your soil is unstable, an expert engineer may recommend a deeper pier foundation to ensure the heavy glass walls never experience torsional stress.

Q4: Can I build a roofed padel court in snowy US regions?

Absolutely, but the roof must be specifically engineered to handle the mandatory snow load requirements of your local state building codes to prevent collapse. A roofed court is a superior commercial investment in northern climates because it protects your revenue stream from being interrupted by winter weather.

Q5: What’s the best turf for high-traffic commercial padel clubs?

Textured monofilament turf with a high Dtex rating is the top choice for commercial facilities because it retains silica sand better and resists fiber crushing. This specific turf type ensures a consistent ball bounce and a higher level of joint protection for players who use the facility multiple times per week.