A pala de padel is a solid-surface racket specifically designed for padel, featuring a perforated face and a composite core instead of traditional strings. Many B2B distributors and professional facility owners face the problem of identifying high-quality equipment in a market flooded with generic, low-durability options. Using substandard gear agitates the risk of performance plateaus and physical injuries like epicondylitis, leading to frequent and costly replacement cycles. The solution lies in understanding the complex architectural build of a professional racket to ensure maximum longevity and player satisfaction.

1. What defines the core structure of a pala de padel?

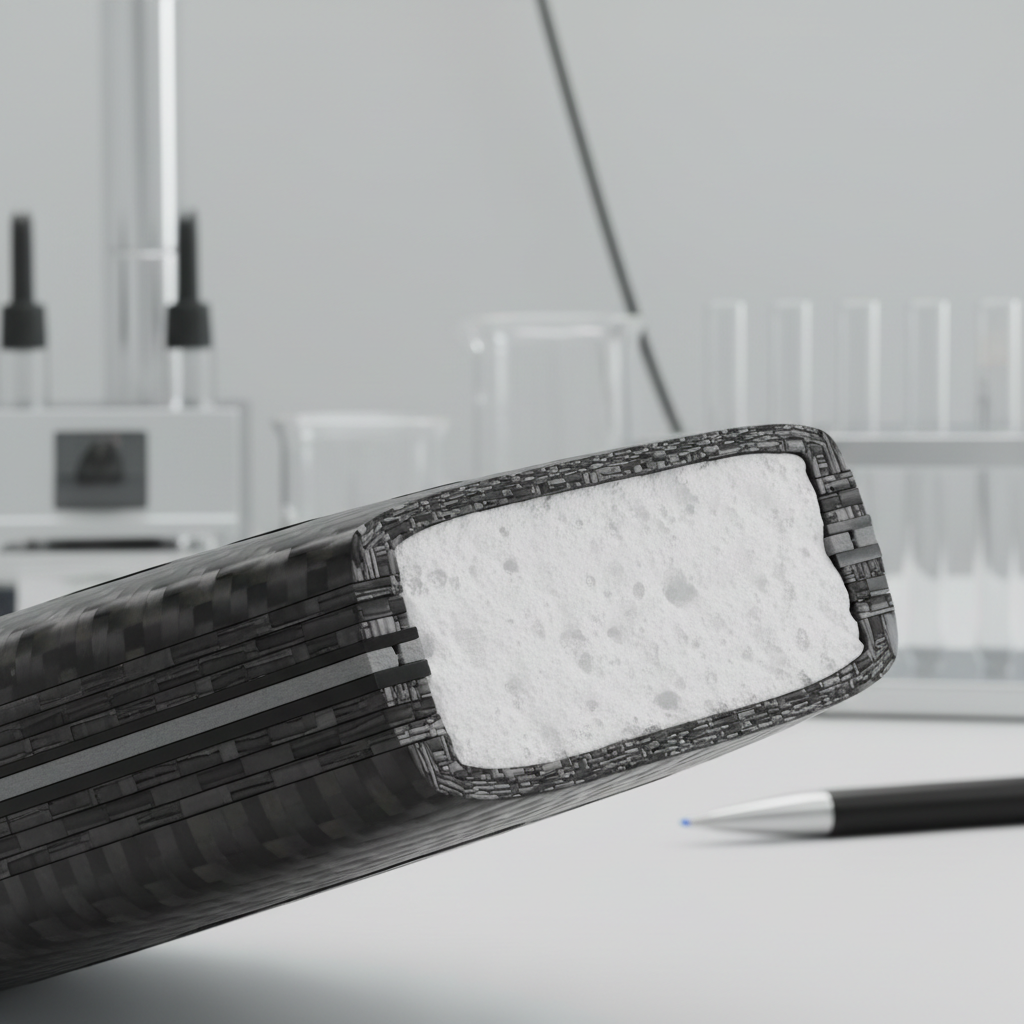

The fundamental structure of a professional racket relies on a solid, non-stringed face that must manage high impact. Unlike tennis rackets, the pala de padel uses a sandwich construction where a foam core is compressed between layers of composite fibers. This solid design allows for a unique aerodynamic profile and specific vibration-dampening qualities.

But that’s not all.

Essential Architecture

- Impact Surface: The flat area that makes contact with the ball.

- Internal Core: Usually made of EVA or Polyethylene foam.

- Frame: The outer tubular skeleton providing rigidity.

Key Takeaway: The core structure must balance weight with structural integrity to survive high-velocity impacts.

| Component | Purpose | Material |

|---|---|---|

| Face | Impact Control | Carbon/Fiberglass |

| Core | Shock Absorption | EVA Foam |

| Frame | Rigid Support | Carbon Fiber |

2. Which materials are essential for a durable pala de padel?

Durability begins with the quality of the resins and fibers used in the lamination process. High-grade carbon fiber is the standard for professional gear because it offers the best strength-to-weight ratio. Without the right bonding agents, the layers can delaminate, causing the racket to lose its “pop” over time.

Here is why.

Premium Composites

- Carbon Fiber: Provides the necessary stiffness for power.

- Epoxy Resin: Acts as the industrial glue holding the layers together.

- Glass Fiber: Often added for increased flexibility and comfort.

Key Takeaway: Material selection directly dictates the lifespan and energy return of the racket face.

| Material | Strength | Flexibility |

|---|---|---|

| 12K Carbon | High | Low |

| Fiberglass | Medium | High |

| EVA Foam | Low | Extreme |

3. How does the balance of a pala de padel affect performance?

The balance point of a racket is the geographical center of its weight distribution. For manufacturing excellence, precision in weight placement determines if a racket is head-heavy or handle-heavy. This shift changes the physics of the swing, favoring either defensive maneuverability or offensive power.

It gets better.

Weight Dynamics

- High Balance: Weight is toward the head for heavy smashes.

- Low Balance: Weight is near the handle for quick reactions.

- Medium Balance: Provides a versatile, all-around feel for most players.

Key Takeaway: Choosing the right balance is the most effective way to prevent arm fatigue during long matches.

| Balance Type | Power Level | Control Level |

|---|---|---|

| Head Heavy | High | Low |

| Even Balance | Medium | Medium |

| Handle Heavy | Low | High |

4. Is the drilling pattern of a pala de padel critical for power?

Drilling holes into a solid face isn’t just for aesthetics; it is a calculated aerodynamic necessity. The pattern and size of the holes affect the drag coefficient of the racket as it moves through the air. Furthermore, the distribution of these holes defines the size and responsiveness of the sweet spot.

Think about this.

Aerodynamic Engineering

- Linear Patterns: Improve structural stability of the frame.

- Concentric Patterns: Help expand the effective hitting area.

- Variable Diameters: Optimize airflow to increase swing speed.

Key Takeaway: A well-engineered drilling pattern reduces air resistance without compromising the strength of the face.

| Hole Layout | Main Benefit | Impact Feel |

|---|---|---|

| Wide Spacing | Durability | Stiffer |

| Dense Spacing | Spin | Softer |

| Aerodynamic | Speed | Responsive |

5. Why is the handle grip vital for every pala de padel?

The handle is the primary interface between the athlete and the equipment. We prioritize ergonomic safety at our facility to ensure that vibrations from off-center hits don’t reach the elbow. A high-quality grip must provide both tackiness for control and absorbency for sweat management.

You might be wondering.

Ergonomic Contact

- Synthetic Overgrips: Offer customizable thickness and texture.

- Safety Wrist Strap: A mandatory feature for player safety.

- Under-grip Technology: Specialized materials that filter out harmful vibrations.

Key Takeaway: The grip is the final line of defense against repetitive strain injuries in professional players.

| Grip Feature | Function | Material |

|---|---|---|

| Perforations | Sweat Wicking | Polyurethane |

| Texture | Slip Resistance | Rubberized Resin |

| Safety Cord | Security | Nylon |

6. Can a luxury pala de padel improve your professional game?

Luxury equipment often utilizes proprietary technologies that generic models simply cannot match. Higher manufacturing standards ensure that every unit has a consistent weight and balance, which is vital for competitive play. Investing in a premium build means getting a more reactive core that maintains its properties for hundreds of hours.

The real story is.

Performance Tiers

- Customized Weight: Precision within a +/- 2-gram tolerance.

- Anti-Shock Systems: Internal bridges that dissipate energy.

- Surface Texture: 3D molded patterns for enhanced ball spin.

Key Takeaway: Premium rackets offer a level of consistency that allows players to trust their equipment in high-pressure moments.

| Tier | Core Life | Customization |

|---|---|---|

| Generic | Low | None |

| Standard | Medium | Limited |

| Luxury | High | Full |

The application of carbon fiber is a manual, high-precision task that determines the racket’s “feel.” Technicians at our production center carefully layer sheets of carbon weave over the core before vacuum sealing them. This process removes air bubbles and ensures a perfect bond that won’t crack under pressure.

Here is the deal.

Advanced Layering

- 3K Weave: A standard, flexible weave for balanced play.

- 12K Weave: Denser and stiffer for advanced offensive power.

- Directional Bias: Aligning fibers to manage torque during the swing.

Key Takeaway: The density of the carbon weave is the primary factor in determining the racket’s stiffness level.

| Weave Type | Thread Count | Player Level |

|---|---|---|

| 3K Carbon | 3,000 | Intermediate |

| 12K Carbon | 12,000 | Advanced |

| 18K Carbon | 18,000 | Professional |

8. What happens when a ball hits the pala de padel sweet spot?

The sweet spot is where the core and the face work in perfect harmony to maximize energy transfer. When the ball hits this zone, the foam compresses and then rapidly expands, launching the ball with minimal effort from the player. Off-center hits, by contrast, lose energy to vibration and torque.

Look at the facts.

The Moment of Impact

- Energy Transfer: Converting swing speed into ball velocity.

- Vibration Filtering: The core’s ability to keep the handle stable.

- Sound Profile: A clean “pop” indicates a high-quality internal bond.

Key Takeaway: A larger sweet spot makes the racket more “forgiving” and improves the average ball output for all players.

| Impact Zone | Ball Exit | Vibration |

|---|---|---|

| Sweet Spot | High | Low |

| Edge | Low | High |

| Throat | Minimal | Extreme |

9. Which studio tests ensure the quality of a pala de padel?

Quality control involves a series of rigorous mechanical tests to guarantee performance standards. We use hydraulic presses to measure the compression rate of the core and digital scales to verify the balance point. Every racket must pass these benchmarks before it is approved for professional use.

Wait, there’s more.

Quality Assurance

- Stress Test: Simulating thousands of hits to check for fractures.

- Torsion Test: Measuring the frame’s resistance to twisting.

- Resonance Check: Ensuring the internal core hasn’t detached from the skin.

Key Takeaway: Stringent testing prevents “dead” rackets from reaching the market and protects the distributor’s reputation.

| Test Type | Metric | Tolerance |

|---|---|---|

| Weight | Grams | +/- 2g |

| Balance | Millimeters | +/- 3mm |

| Hardness | Shore | +/- 5% |

10. Where does the design phase for a new pala de padel begin?

Every high-performance racket starts on a designer’s desk with computer-aided design (CAD) software. We model the internal bridges and hole placements to optimize the center of gravity before a single prototype is built. This phase allows us to simulate how different foam densities will interact with carbon layers.

This is crucial.

Conceptualization

- CAD Modeling: Creating the 3D skeleton of the frame.

- Material Simulation: Predicting how fibers will react to impact.

- Ergonomic Prototyping: Ensuring the handle fits the average hand perfectly.

Key Takeaway: Advanced design software reduces the trial-and-error phase, leading to more innovative and reliable equipment.

| Phase | Tool | Outcome |

|---|---|---|

| Design | CAD Software | Blueprint |

| Prototype | 3D Printing | Fit Check |

| Final Mold | Steel CNC | Production |

Understanding the technical nuances of the pala de padel is essential for any professional looking to source or manufacture elite equipment. From the molecular density of the EVA core to the precision of the carbon fiber layering, every detail influences the final performance on the court. By prioritizing high-grade materials and rigorous testing, businesses can provide gear that truly enhances the game. If you are ready to upgrade your facility’s inventory or develop a custom line of equipment, contact us today for expert guidance.

FAQ

- Can I build my own pala de padel at home?

Achieving the industrial compression levels and safety standards required for a professional racket is nearly impossible without specialized molds and high-heat resins. - What’s the best shape for a beginner versus a pro?

Beginners usually benefit from a round shape with a low balance for control, while pros often choose teardrop or diamond shapes for increased leverage and power. - How do I know if my racket’s core is failing?

A noticeable change in the sound of the hit or a sudden loss of ball exit speed usually indicates that the internal foam has lost its elasticity or delaminated from the face. - Can I change the balance of a racket after it is built?

Yes, you can use specialized lead or tungsten tapes on the frame to move the balance toward the head, or add extra overgrips to pull the weight toward the handle. - What’s the best way to extend the life of the racket?

Avoid extreme temperatures, such as leaving it in a car, and use a frame protector to prevent the tubular carbon skeleton from cracking during wall impacts.