A padel racquet is a solid, stringless sports implement used to strike the ball in the high-speed game of padel. You may find yourself struggling to control the ball or feeling wrist fatigue after a short session on the court. Using a poorly designed tool not only limits your performance but also increases the risk of chronic injuries like tennis elbow. By understanding the engineering behind a high-quality padel racquet, you can select or even build the perfect gear to dominate your next match.

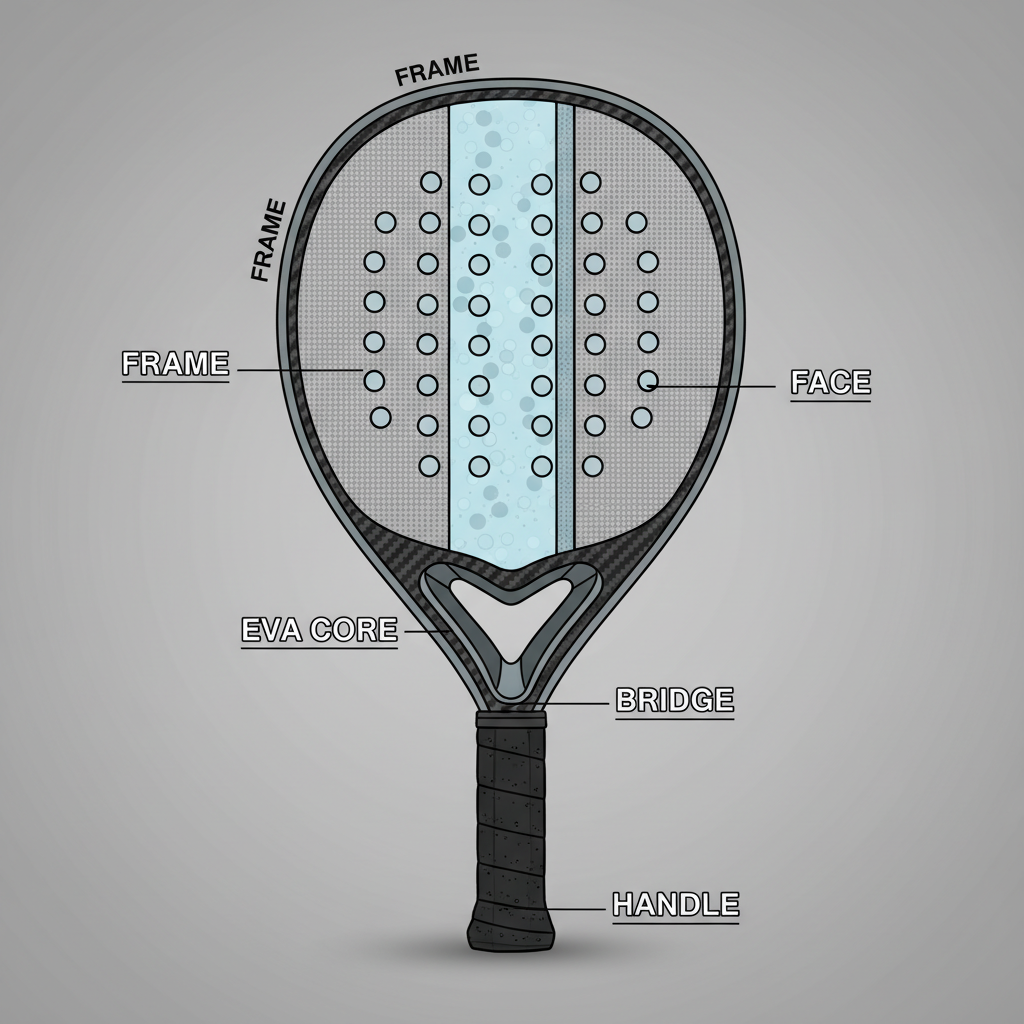

A padel racquet is a short-handled, perforated paddle made of composite materials like carbon fiber and EVA foam.

Defining the physical dimensions

Believe it or not, the dimensions of the frame are strictly regulated to maintain the game’s balance.

- Total length: Maximum of 45.5 centimeters.

- Profile thickness: Standardized at 38 millimeters.

- Face width: Generally capped at 26 centimeters.

Understanding the strike surface

Look: the holes are not just for aesthetics; they are vital for reducing air resistance during your swing.

- Hole diameter: Typically between 9 and 13 millimeters.

- Face type: Solid composite with a textured finish for spin.

- Materials: Carbon fiber or fiberglass outer skins.

Key Takeaway: The racquet is a compact, aerodynamic tool designed for high-precision play in confined spaces.

| Feature | Specification |

|---|---|

| Max Length | 45.5 cm |

| Max Width | 26 cm |

| Standard Thickness | 38 mm |

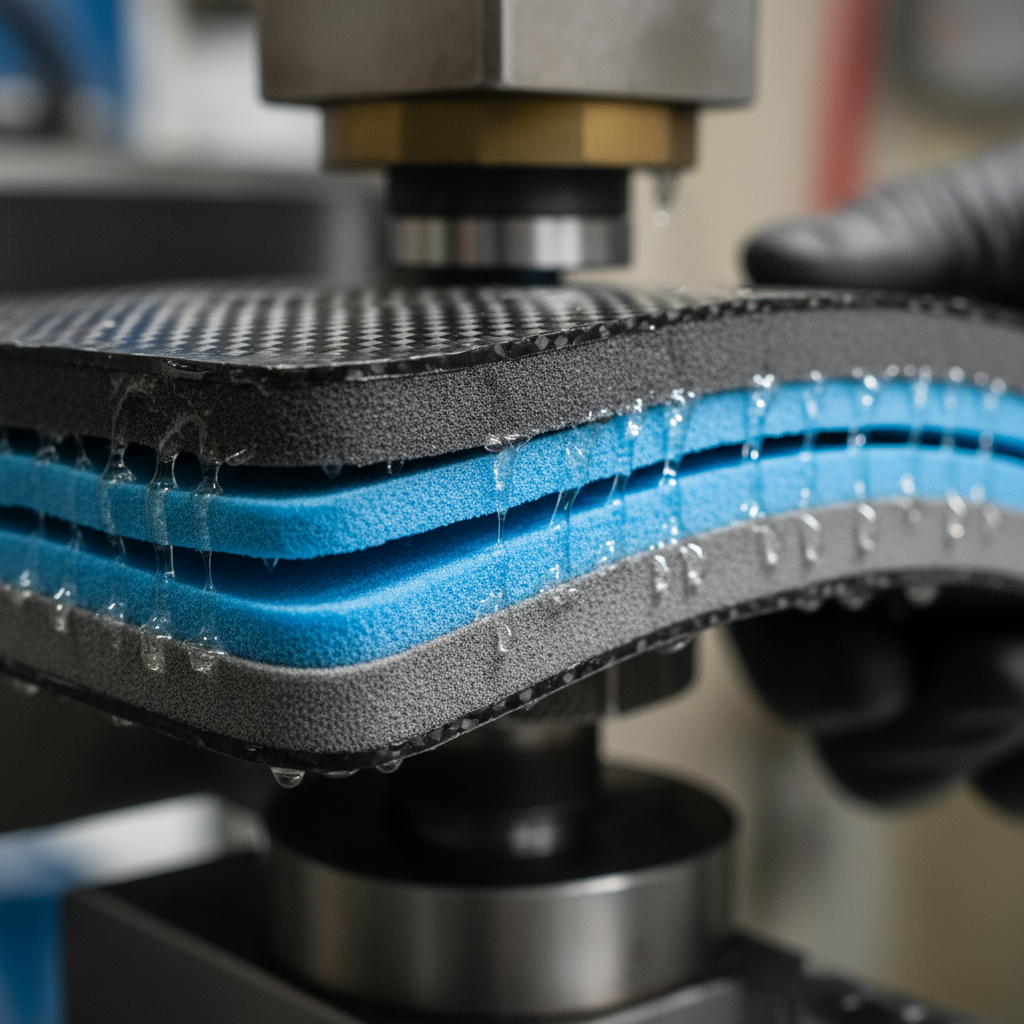

Construction involves layering composite skins over a synthetic foam core through a process of heat and pressure.

The frame and bridge

Think about it: the bridge is the most stressed part of the racquet because it handles the vibration from every impact.

- Frame: Typically tubular carbon fiber for rigidity.

- Bridge: Reinforced to prevent structural snapping.

- Handle: The foundation for grip application and wrist straps.

The face layering process

In short, the number of layers determines how much “pop” or power the racquet generates.

- Base layer: Fiberglass for elasticity and comfort.

- Top layer: Carbon fiber for strength and durability.

- Resin: Industrial epoxy to bond the layers to the foam.

Key Takeaway: Layering determines the balance between flexibility and rigid power.

| Component | Material Function |

|---|---|

| Bridge | Vibration Dampening |

| Frame | Structural Integrity |

| Face Sheets | Impact Response |

The primary materials used to create a padel racquet are carbon fiber, fiberglass, and epoxy resin.

Carbon fiber vs Fiberglass

As it turns out, the weave of the carbon fiber (3K, 12K, or 18K) completely changes the feel of the strike.

- Fiberglass: Offers a softer touch for beginners.

- 3K Carbon: Provides a balanced, intermediate feel.

- 18K Carbon: Extremely stiff for maximum professional power.

The role of epoxy resins

It gets better: modern resins are engineered to resist high temperatures and prevent the racquet from softening in the sun.

- Bonding: Connects fibers to the internal foam core.

- Impact resistance: Prevents delamination after hitting walls.

- UV protection: Stops the materials from becoming brittle over time.

Key Takeaway: Material choice dictates whether the racquet is “soft” or “hard” on impact.

| Material | Player Level | Primary Benefit |

|---|---|---|

| Fiberglass | Beginner | Comfort/Flex |

| Carbon 3K | Intermediate | Durability |

| Carbon 18K | Professional | Max Power |

The internal core of the racquet is made from EVA rubber or Polyethylene foam to provide shock absorption and power.

EVA Rubber characteristics

Let’s face it: most players prefer EVA because it has a “memory” that allows the racquet to return to its original shape instantly.

- Soft EVA: Increases ball exit speed with less effort.

- Hard EVA: Provides superior control for advanced players.

- Black EVA: Known for higher density and longer lifespan.

FOAM vs Hybrid cores

The best part? If you suffer from tennis elbow, FOAM cores absorb nearly all the vibration before it reaches your arm.

- Polyethylene (FOAM): Highly elastic and shock-absorbent.

- Hybrid Cores: Combines EVA and FOAM for a versatile feel.

- Durability: FOAM typically has a shorter lifespan than EVA.

Key Takeaway: The core is the “engine” of the racquet, determining its power and comfort levels.

| Core Type | Density | Impact Feel |

|---|---|---|

| Soft EVA | Low | Elastic |

| Black EVA | High | Solid |

| FOAM | Ultra-low | Absorbing |

Weight for a padel racquet typically ranges from 350 to 390 grams, influencing both speed and impact force.

Lightweight advantages

Here is the deal: a lighter racquet allows you to react much faster when you are standing at the net.

- Target weight: 350g to 360g.

- Maneuverability: Easier to swing during rapid volleys.

- Injury prevention: Reduces strain on the shoulder and elbow.

Heavyweight power

Believe it or not, adding just 10 grams to the head can significantly increase the speed of your smashes.

- Target weight: 375g to 385g.

- Stability: Moves less when hitting fast incoming balls.

- Power: Provides more mass behind the strike.

Key Takeaway: Balance your racquet’s weight with your physical strength to avoid injury.

| Weight Range | Classification | Target Player |

|---|---|---|

| 350g – 360g | Lightweight | Juniors/Women |

| 360g – 370g | Standard | Most Adults |

| 375g+ | Heavyweight | Advanced Hitters |

You can customize your racquet by adding lead tape for balance or overgrips for ergonomic comfort.

Adjusting balance with lead tape

Think about it: moving the balance toward the head makes the racquet feel more aggressive.

- Head Heavy: Increases leverage for smashes.

- Handle Heavy: Increases control and defensive speed.

- Customization: Adhesive weights can be applied to the frame.

Customizing the grip and overgrips

You might be wondering: why do pros use so many overgrips? It is to prevent hand cramps by matching handle size to palm size.

- Overgrips: Add tackiness and sweat absorption.

- Hesacore: Specialized hexagonal grips for vibration reduction.

- Size: A thicker grip reduces the risk of the racquet twisting.

Key Takeaway: Customization allows you to fine-tune a mass-produced racquet for your specific biomechanics.

| Customization | Method | Result |

|---|---|---|

| Balance | Lead Tape | Power/Control shift |

| Grip Size | Overgrips | Better ergonomics |

| Protection | Frame Tape | Scratch prevention |

Manufacturers test a padel racquet for durability, flexibility, and fatigue resistance through standardized lab impact cycles.

Flex and fatigue testing

As it turns out, a racquet that is too stiff will crack, while one that is too soft will lose its bounce.

- Static load: Measures how much the face bends under pressure.

- Cycle testing: Simulates 10,000 hits to check for material fatigue.

- Core recovery: Ensures the EVA returns to shape in milliseconds.

The durability drop test

Look: these tests ensure that your racquet won’t explode into shards if you accidentally hit the glass wall.

- Impact testing: Dropping heavy weights on the frame edges.

- Resin bond test: Checking for air bubbles that cause delamination.

- Safety standards: Meets European regulations for sports equipment.

Key Takeaway: Professional testing ensures your racquet is both high-performing and safe to use.

| Test Category | Metric | Goal |

|---|---|---|

| Stiffness | Shore Hardness | Consistent Feel |

| Durability | Cycle Count | Long Product Life |

| Balance | Point CM | Accurate Swing Weight |

Three distinct shapes—round, teardrop, and diamond—define the playstyle and sweet spot location of the racquet.

The Round shape for control

Believe it or not, the round shape has the largest sweet spot, making it the most forgiving design for newcomers.

- Sweet spot: Centered and wide.

- Balance: Low (near the handle).

- Focus: Defensive play and control.

Diamond and Teardrop shapes

The best part? The teardrop shape is the “perfect middle ground” for players who want both power and control.

- Teardrop: Hybrid balance for versatile intermediate players.

- Diamond: Top-heavy balance for professional power-hitters.

- Sweet spot: Located higher up the face on diamond models.

Key Takeaway: Your choice of shape should reflect whether you prioritize control or raw power.

| Shape | Balance | Skill Level |

|---|---|---|

| Round | Low | Beginner |

| Teardrop | Medium | Intermediate |

| Diamond | High | Professional |

Maintaining a padel racquet requires thermal protection and regular replacement of the protective tape on the frame.

Thermal protection and storage

In short, leaving your racquet in a hot car can melt the resin and ruin the internal foam core forever.

- Insulated bags: Protect against extreme heat and cold.

- Dryness: Prevents moisture from seeping into the core holes.

- Sunlight: Prolonged UV exposure can degrade the carbon fiber.

Replacing overgrips and protectors

It gets better: a simple 5-dollar frame protector can save you from having to buy a 200-dollar replacement racquet.

- Frame tape: Absorbs the impact from scraping against walls.

- Overgrip replacement: Should be done every 5 to 10 matches.

- Cleaning: Wipe with a damp cloth to remove sweat and sand.

Key Takeaway: Simple preventative care can double the lifespan of your expensive equipment.

| Task | Frequency | Benefit |

|---|---|---|

| New Overgrip | Every 5-10 matches | Slip prevention |

| Frame Check | After every game | Early crack detection |

| Thermal Storage | Always | Core integrity |

Building a racquet involves shaping a foam core, hand-layering composite fabrics, and curing the assembly in a vacuum-sealed mold.

Preparing the mold and core

Think about it: the mold must be perfectly smooth, or the carbon fiber will have weak points and air pockets.

- CNC Machining: Used to create the aluminum racquet mold.

- Release Agent: Applied to the mold so the resin doesn’t stick.

- Core Shaping: Cutting the EVA foam to the exact racquet profile.

Lamination and vacuum curing

Look: the vacuum pump is the most important tool because it sucks out every tiny air bubble from the resin.

- Lay-up: Placing carbon sheets and resin over the foam core.

- Vacuum bagging: Applying consistent pressure for a perfect bond.

- Drilling: The holes are drilled only after the racquet is fully cured.

Key Takeaway: Building a racquet is a precision engineering task that rewards attention to detail.

| Step | Action | Critical Factor |

|---|---|---|

| Lay-up | Layering fibers | Orientation/Alignment |

| Infusion | Applying resin | Even distribution |

| Finishing | Drilling holes | Symmetrical pattern |

Frequently Asked Questions

Can I use a tennis racquet for padel?

No, the rules and physics of the game require a solid-faced padel racquet, as tennis strings would break and offer no control on the specific ball used in padel.

Can I repair a crack in my padel racquet?

Small surface scratches can be ignored, but structural cracks in the frame or face usually cannot be safely repaired and indicate that you need a replacement.

Can I change the weight of my racquet after buying it?

Yes, you can increase the weight and change the balance by applying adhesive lead or tungsten tape to the frame.

Can I wash my padel racquet with water?

You should only use a slightly damp cloth to wipe the surface; never submerge it in water, as moisture can seep into the holes and damage the internal foam core.

Can I build a racquet without a vacuum pump?

While possible with hand-clamping, it is not recommended because air bubbles trapped in the resin will significantly weaken the structure and cause it to fail during a match.