Investing in a new sports facility often brings significant anxiety regarding material durability and player safety. Owners frequently worry about rust corroding metal fences or glass panels shattering under impact. Here is the deal. Implementing precise design specifications eliminates these structural risks before construction even begins. We manufacture premium courts for hundreds of satisfied clients globally. My expertise in this industry guarantees your project will meet strict international safety standards. This guide details every technical specification required for a durable and profitable installation.

Table of Contents

- Official Dimensions and Layout

- Wall and Fence Standards

- Markings and Net Specifications

- Structural Materials: Iron vs. Fiberglass

- Glass Safety and Thickness

- Turf Selection for Playability

- Lighting Metrics and Lux Levels

- Construction Process Steps

- Club Owner Advantages

- Budget Influencers

- Conclusion

- FAQ

1. What are the official dimensions for a compliant padel court design?

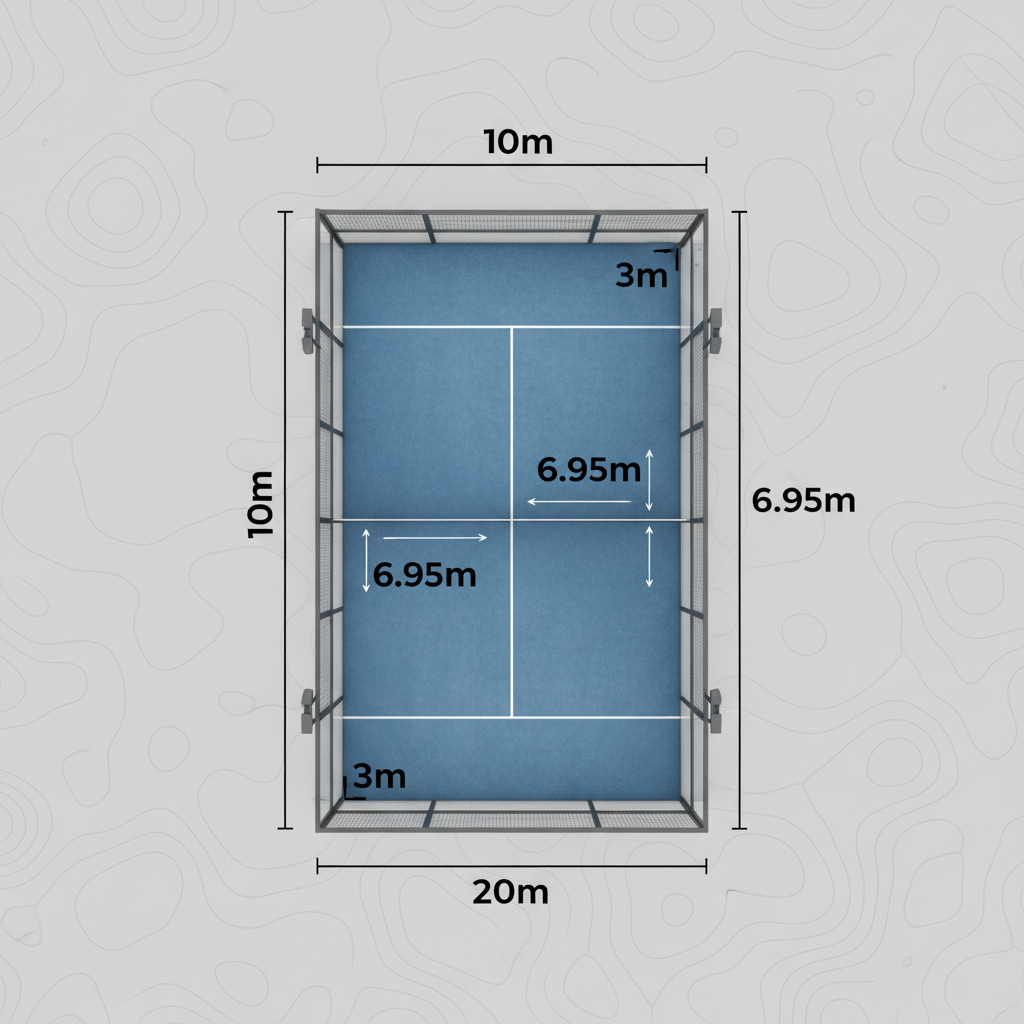

Precision defines the game of padel more than any other factor. The International Padel Federation (FIP) mandates a rectangular area measuring exactly 20 meters in length and 10 meters in width. This creates a total playing surface of 200 square meters per court. Compliance allows for a strict tolerance of only 0.5% regarding these measurements. You might be wondering, does the total footprint matter beyond these lines? Absolutely.

We recommend a total footprint of 21 meters by 11 meters for installation. This extra space ensures safety runs and proper structural anchoring. Indoor facilities must also consider vertical space carefully. A minimum clear height of 6 meters is required for official play. New constructions should aim for 8 meters to allow high lobs without obstruction. adhering to these metrics ensures your facility can host official tournaments.

| Dimension Parameter | Measurement | Tolerance |

|---|---|---|

| Court Length | 20 meters | ±0.5% |

| Court Width | 10 meters | ±0.5% |

| Minimum Height | 6 meters | N/A |

| Rec. Height (New) | 8 meters | N/A |

| Total Footprint | 21 x 11 meters | N/A |

2. How do wall and fence heights impact standard padel court design?

The enclosure system is an integral part of the playing field rather than just a boundary. Back walls must stand exactly 4 meters high overall. The first 3 meters consist of solid materials like glass or concrete to provide predictable ball rebound. But here is the kicker. The top 1 meter uses metallic mesh fencing to contain erratic shots.

Side walls often feature a stepped design for specific tactical reasons. The first 2 meters from the back corner stand 3 meters high. The next 2-meter section drops down or stays consistent depending on the court variant. Standard wire mesh fencing completes the enclosure sides. This mesh typically features square apertures between 50mm and 70.8mm. This size prevents balls from getting stuck while allowing spectators to view the action. Tension in this mesh must be high to ensure player safety during impacts.

| Feature | Standard Double Court | Single Court |

|---|---|---|

| Court Width | 10 meters | 6 meters |

| Back Wall Height | 4 meters | 4 meters |

| Side Wall Step | 3m stepped to 2m | 3m stepped to 2m |

| Fence Height | 3m or 4m | 3m or 4m |

3. What specific markings and net specs define padel court design?

Court markings dictate the flow of the game and must offer high contrast against the turf. All lines should measure precisely 5 centimeters in width. Service lines sit 6.95 meters from the net on both sides. A central service line divides the area between the net and service line into two equal zones. What is the real story? Even a centimeter of error here can render a court unplayable for ranked matches.

The net itself splits the court into two symmetric halves. It spans the full 10-meter width with a maximum tension cable diameter of 1 centimeter. The height specifications are critical for fair play. The net must hang at 0.88 meters in the center and rise to 0.92 meters at the posts. These posts should not exceed 1.05 meters in height. They must feature rounded edges to minimize injury risks during fast-paced play near the boundaries.

4. Why choose fiberglass or iron for structural padel court design?

Material selection dictates the longevity of your investment in harsh environments. Galvanized iron remains the industry standard for most commercial installations. This material offers immense structural rigidity and resists deformation under heavy wind loads. We treat our Padel Structure with hot-dip galvanization to prevent rust.

Fiberglass structures are emerging as a superior alternative for coastal areas. Ready for the good part? Fiberglass resists saline corrosion completely and dampens ball impact noise significantly. This reduces noise pollution for neighbors and lowers maintenance costs over time. Iron requires regular checks for scratches in the powder coating. Fiberglass maintains its integrity without painting. Choosing between them depends on your local climate conditions and budget flexibility.

| Feature | Galvanized Iron | Fiberglass |

|---|---|---|

| Corrosion Resistance | Moderate (needs coating) | Excellent (Native) |

| Structural Rigidity | Very High | High |

| Impact Noise | High (Metal clang) | Low (Dampened) |

| Maintenance | Periodic painting | Minimal |

| Cost | Cost-Effective | Premium |

5. What glass specifications are required for safe padel court design?

Safety is the absolute priority when selecting large glass panels for sport. Standard courts utilize 18 pieces of tempered glass measuring 2×3 meters each. This is where it gets interesting. We recommend 12mm thickness for all outdoor installations to withstand wind and thermal stress. Indoor courts can safely use 10mm glass if climate control is stable.

Tempered glass is mandatory because it shatters into blunt granules rather than sharp shards upon failure. Countersunk holes for fittings prevent stress cracks around the screws. Panoramic Padel Court designs remove rear metal pillars for unobstructed viewing. This requires thicker glass and specialized connectors to maintain structural integrity. Using non-tempered or thinner glass is a negligence risk no club owner should take.

6. How does turf selection define the playability of padel court design?

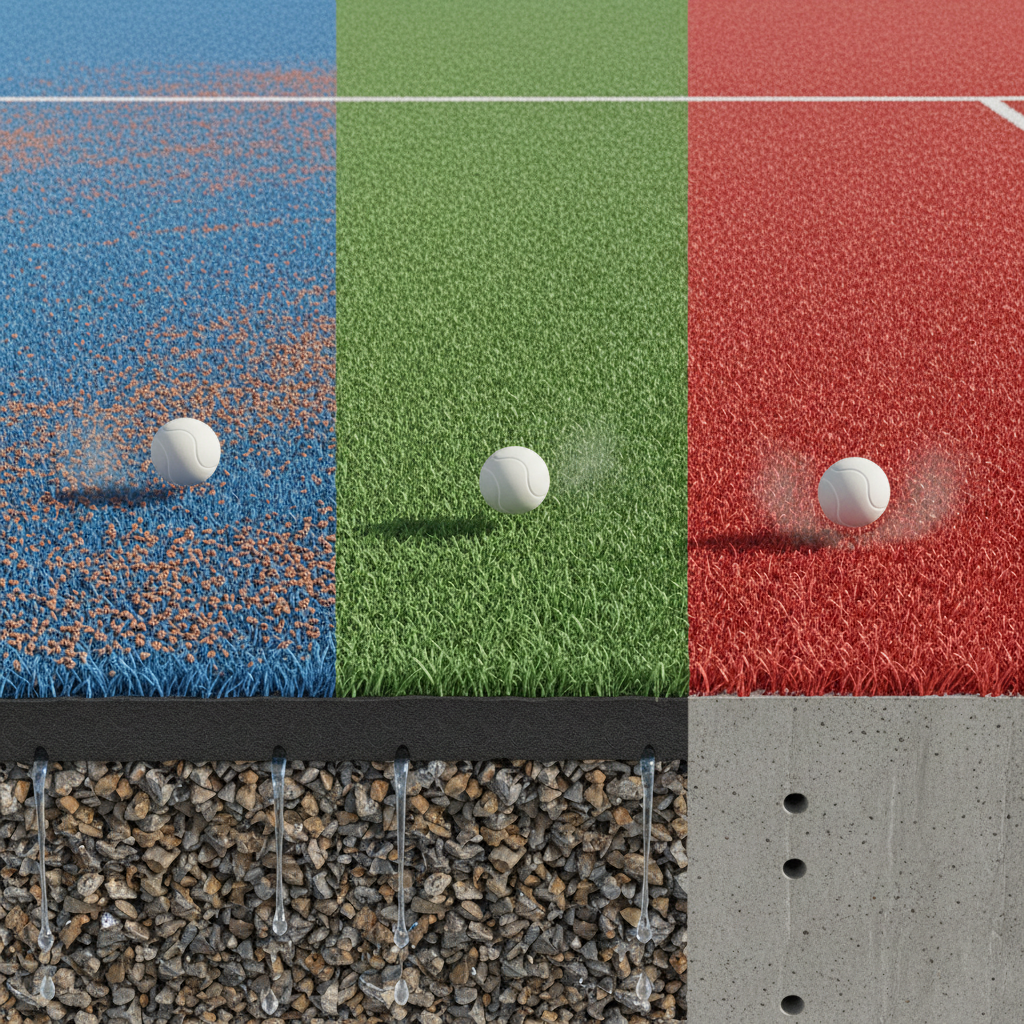

The interaction between the ball and the surface defines the speed of the game. Artificial turf filled with silica sand is the universal standard. Why does this matter? The sand supports the fibers and allows players to slide safely during extreme defensive moves. We offer two main fiber types: monofilament and fibrillated.

Monofilament fibers are durable and provide a consistent, slower ball bounce ideal for modern play. Fibrillated tape fibers hold sand better but wear down faster visually. Texturized Padel Grass curls the fibers to trap sand inside. This prevents slippery patches and creates a uniform blue or green aesthetic. Properly installed turf prevents knee injuries by allowing controlled rotation of the foot.

| Turf Type | Characteristics | Best For |

|---|---|---|

| Monofilament | Individual strands, durable | High traffic clubs |

| Fibrillated | Mesh-like, holds sand well | Entry level courts |

| Texturized | Curled fibers, encapsulates sand | Pro tournaments |

7. What lighting metrics are critical for effective padel court design?

Effective illumination allows revenue generation to continue long after sunset. The European Standard EN 12193 dictates specific lux levels for different play classes. Recreational courts need a minimum of 200 lux. Let’s face it. Clubs wanting to host tournaments must provide at least 500 lux to meet broadcast standards.

Glare reduction is just as important as brightness. Padel LED Lighting should be mounted at a height of 6 meters or more. We position fixtures outside the court sidelines to prevent blinding players during overhead smashes. Asymmetric lenses direct light onto the court surface without spilling into neighboring properties. High-quality drivers prevent flickering which can disrupt high-speed video recording.

8. What is the step-by-step process for executing padel court design?

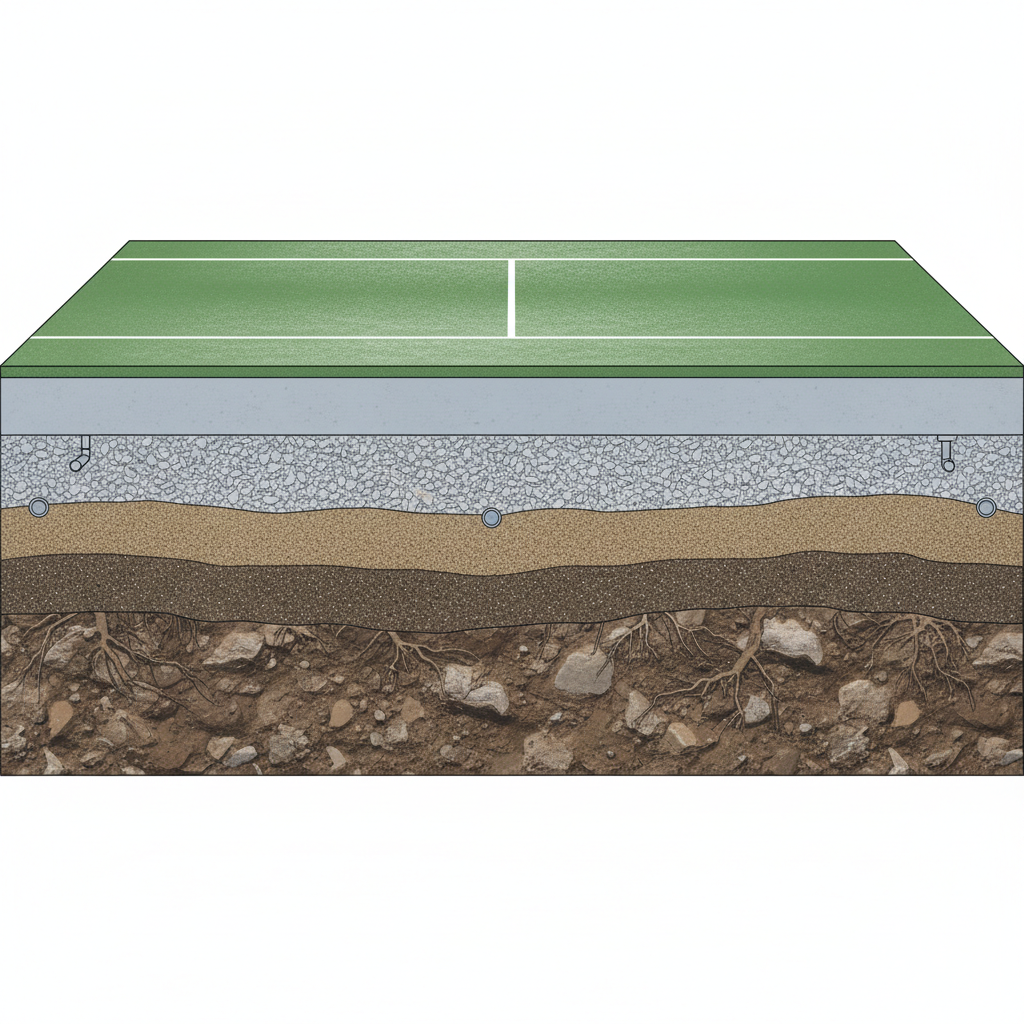

Successful installation relies entirely on a perfectly flat foundation. Think about this. A deviation of just a few millimeters can cause glass panels to crack under tension. The process begins with excavating the site and laying a perimeter ring beam. This beam supports the heavy steel columns.

We pour a reinforced concrete slab of 15 centimeters thickness inside the ring beam. This slab must have a 0.5% to 1% slope for outdoor drainage. Once the concrete cures, we erect the steel structure and level it precisely. Glass panels are installed next, followed by the artificial turf. The final step involves spreading silica sand and brushing it deep into the fibers.

- Site Excavation: Clearing and leveling the ground.

- Ring Beam: Concrete perimeter for structural load.

- Slab Pouring: 15cm reinforced concrete with slope.

- Structure Assembly: Erecting steel posts and mesh.

- Glass Mounting: Carefully fixing tempered panels.

- Turf & Sand: Laying grass and infilling silica.

9. Why should club owners prioritize professional padel court design?

Space efficiency makes padel one of the most profitable sports investments available. Bottom line? You can fit three padel courts in the space required for a single tennis court. This triples the potential revenue per square meter for your club.

Padel also fosters a highly social environment due to the doubles format and smaller court size. This increases retention rates and bar or café spend. Professional design ensures low maintenance costs over the facility’s lifecycle. Cheap materials lead to rust and glass breakage that close courts and kill revenue. Investing in quality upfront protects your business continuity and enhances player satisfaction.

Budgeting for a court involves more than just the purchase price of the kit. Here is the truth. The civil works and foundation often cost as much as the court itself. Indoor courts cost more initially due to building requirements but suffer less weather wear.

Material choices also drive price variances. Galvanized steel is cheaper than aluminum or fiberglass but may need earlier replacement in humid zones. 12mm glass costs more than 10mm but offers necessary safety for outdoor use. Our Standard Padel Court offers a balanced entry point for clubs. It combines durable materials with cost-effective engineering to maximize ROI.

| Cost Factor | Impact | Recommendation |

|---|---|---|

| Foundation | High (40-50%) | Don’t skimp here |

| Structure | Medium | Galvanized for outdoors |

| Glass | Medium | 12mm is safer |

| Turf | Low | Monofilament for durability |

| Lighting | Low | LED saves energy |

Key Takeaways

- Precision is Mandatory: Adhering to 10x20m dimensions with strict tolerance ensures FIP compliance.

- Material Choice: Galvanized iron or fiberglass dictates the longevity and maintenance needs of your facility.

- Safety First: 12mm tempered glass and proper mesh tension protect players from injury.

- Smart Investment: Padel maximizes revenue by fitting 3 courts in the space of one tennis court.

Ready to build a world-class facility? Visit our SuperbPadel Homepage to get a factory-direct quote today.

Frequently Asked Questions (FAQ)

Q1: What is the exact size of a double padel court?

The standard size for a double padel court is exactly 10 meters in width and 20 meters in length. The playing area totals 200 square meters. An extra clearance zone of 2 meters around the perimeter is recommended.

Q2: How much space is needed between two adjacent courts?

We recommend a minimum distance of 2 to 4 meters between the side walls of adjacent courts. This allows for safe player movement during “out-of-court” play and spectator access. It also facilitates maintenance access.

Q3: What is the standard height for the enclosure walls?

The back walls must be 4 meters high total, comprising 3 meters of solid wall and 1 meter of mesh. The side walls typically step down from 3 meters at the ends to 3 meters or 4 meters in the center depending on the design.

Q4: Can I use existing concrete for the foundation?

Yes, but only if it is perfectly level and structurally sound. Any cracks or unevenness will transfer to the glass panels and cause breakage. We advise a professional inspection before building on old slabs.

Q5: What is the difference between panoramic and standard courts?

Panoramic courts remove the rear vertical steel pillars, using thicker glass and special connectors for visibility. Standard courts have vertical steel posts between glass panels, offering more rigidity at a lower cost.