Introduction

The global explosion of padel has triggered a frantic rush for infrastructure, yet finding a partner who delivers durability and precision is notoriously difficult. Many investors face delayed timelines, rusting structures, and dangerous safety hazards due to poor manufacturing choices.

Imagine investing thousands into a new facility, only to face structural failures or glass breakage within a single year. That’s a nightmare scenario. The wrong choice doesn’t just cost money; it damages your club’s reputation and halts revenue.

This guide demystifies the process, explaining exactly what a top-tier padel court supplier does and how they build courts that last decades. Drawing on industry standards and factory-direct expertise, we outline the roadmap to a successful installation.

1. What Is the Primary Role of a Padel Court Supplier?

A professional padel court supplier manages the entire project lifecycle, from the initial design concept and manufacturing to the final logistical delivery and assembly guidance. They act as the central architect of your project’s physical reality, ensuring that every steel beam and glass panel meets international safety standards.

Manufacturer vs. Distributor

Let’s start with the basics. A true supplier is often the manufacturer, not just a middleman. Distributors simply resell kits with added markups, whereas a factory-direct supplier controls the quality chain from raw steel to the final coat of paint.

- OEM Capabilities: Custom branding and color options.

- Quality Control: Direct oversight of welding and galvanization.

Turnkey Design Solutions

Top suppliers don’t just sell parts; they offer turnkey design solutions that fit your specific site topography. They calculate wind loads and foundation requirements to ensure your courts remain standing during storms.

Key Takeaway: A supplier is your strategic partner, not just a vendor.

| Feature | Factory-Direct Supplier | Local Distributor |

|---|---|---|

| Cost | Lower (No markup) | Higher (Resale markup) |

| Customization | High (OEM available) | Low (Standard kits) |

| Accountability | Single point of contact | Split responsibility |

Analysis: Choosing a manufacturer over a distributor ensures direct accountability for every component of your court.

2. How Does a Padel Court Supplier Handle Installation?

A reputable supplier handles installation by providing detailed technical schematics and often deploying specialized teams to ensure precise assembly of the structure. They bridge the gap between a pile of parts and a playable, safe facility.

The Site Analysis Phase

Before a single bolt is tightened, the supplier must verify the foundation. Here is the secret. A court is only as good as the concrete slab beneath it; suppliers provide the exact engineering loads to your local civil works contractor to prevent sinking or cracking.

The Assembly Process

The installation team meticulously erects the steel frame, anchors it to the ground, and installs the heavy glass panels with millimeter precision. This phase is critical, as even a slight misalignment can cause “dead spots” in the ball bounce or dangerous stress on the glass.

- Leveling: Laser-guided adjustment of posts.

- Anchoring: Chemical or mechanical fixation to concrete.

Key Takeaway: Precision during the 6-phase installation method prevents future structural failures.

| Phase | Activity | Responsibility |

|---|---|---|

| 1. Survey | Check foundation level | Client/Contractor |

| 2. Frame | Erect steel pillars | Supplier Team |

| 3. Glass | Install 12mm panels | Supplier Team |

| 4. Turf | Lay and sand turf | Supplier Team |

Analysis: Poor installation can ruin even the highest quality materials, making expert assembly non-negotiable.

3. What Features Define a Top Padel Court Supplier?

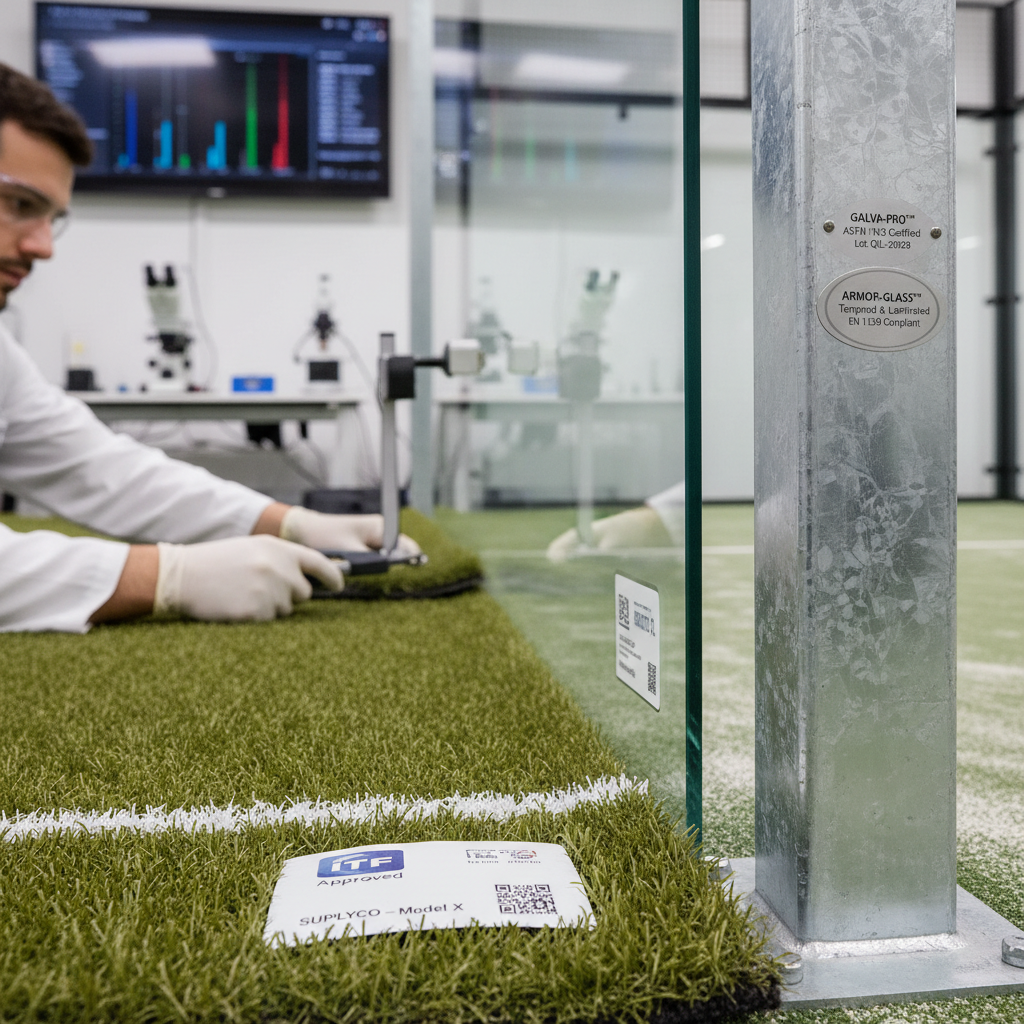

Top suppliers are defined by their ability to integrate advanced safety features and robust engineering directly into their reinforced padel structure. They prioritize long-term durability over short-term cost-cutting, ensuring the court can withstand heavy daily use.

Structural Integrity

Does the supplier use hot-dip galvanized steel? This feature is non-negotiable for outdoor courts to prevent rust. High-quality structures are engineered to withstand wind gusts of up to 100 km/h, protecting both players and your investment.

Safety Glass Standards

You need to know this. The glass walls are the most vulnerable part of the court. Leading suppliers use 12mm tempered glass with countersunk holes and flush joints to prevent erratic ball bounces and injury.

- Anti-collision systems

- Flush-mounted mesh

- Laser-cut components

Key Takeaway: Engineering features are the invisible guardians of player safety.

| Feature | Standard Court | Premium Court |

|---|---|---|

| Steel Profile | 2mm thickness | 3mm thickness |

| Galvanization | Electro-galvanized | Hot-dip galvanized |

| Screws | Stainless 304 | Stainless 316 (Marine) |

Analysis: Advanced engineering features dictate the longevity and safety profile of your facility.

4. Which Models Do Padel Court Supplier Companies Offer?

Suppliers typically offer a diverse range of models, from robust standard frames for clubs to elegant super-panoramic designs for televised tournaments. Each model serves a different purpose, balancing durability with aesthetic appeal.

Panoramic vs. Standard

Think about this. Do you want maximum visibility or maximum durability? Panoramic courts remove the rear corner pillars for an unobstructed view, making them ideal for center courts, while standard models offer superior rigidity for high-traffic rental use.

Indoor and Roofed Solutions

For climates with heavy rain or sun, suppliers offer models with integrated roofing systems. These covers are engineered to fit the court dimensions perfectly, allowing for year-round revenue regardless of the weather.

- Standard Model: Robust, cost-effective.

- Panoramic Model: Viewer-friendly, premium look.

- Roofed Model: All-weather capability.

Key Takeaway: The right model choice depends entirely on your club’s specific business goals and location.

| Model | Best For | Visibility | Cost |

|---|---|---|---|

| Standard | Daily Rentals | Good | Low |

| Panoramic | Tournaments | Excellent | Medium |

| Roofed | Rainy Climates | Good | High |

Analysis: Panoramic courts often command higher rental fees due to their premium playing experience.

5. What Materials Does a Padel Court Supplier Recommend?

A quality supplier recommends specific materials like 12mm tempered glass and specialized padel turf to ensure consistent ball performance and safety. They avoid generic materials that cannot withstand the unique stresses of the sport.

Artificial Turf Selection

The playing surface is critical. Suppliers often recommend monofilament turf for its durability and better grip, or fibrillated turf for faster sand stabilization. The memory of the fibers determines how well the ball bounces over time.

Lighting and Mesh

It gets better. Modern LED lighting systems are designed to minimize glare for players while providing 300+ lux of brightness. The steel mesh must be rigid enough to rebound the ball but flexible enough not to warp upon impact.

- Monofilament Turf: High durability.

- Tempered Glass: 12mm thickness.

- LED Floodlights: 200W asymmetric.

Key Takeaway: The quality of raw materials directly defines the playability of the court.

| Component | Recommendation | Benefit |

|---|---|---|

| Turf | Texturized Monofilament | Consistent bounce |

| Glass | 12mm Tempered | Impact safety |

| Lights | 8x 200W LED | TV-ready visibility |

Analysis: Investing in premium materials upfront significantly reduces Operating Expenses (OpEx) later.

6. Why Choose a Factory-Direct Padel Court Supplier?

Choosing a factory-direct supplier eliminates unnecessary markups and provides you with a direct line of communication to the production floor. This relationship fosters transparency and allows for rapid customization that distributors simply cannot match.

Significant Cost Savings

By skipping the middleman, you can save approximately 30% on procurement costs. These savings can be reinvested into better amenities for your club, such as a pro shop or a bar/lounge area.

Direct Communication

Here’s the deal. When you have a technical question about the foundation, you get an answer from the engineer who designed it, not a salesperson. This direct loop accelerates the project timeline and reduces errors.

- No Middlemen: Lower prices.

- Faster Answers: Direct support.

- Customization: Easy changes.

Key Takeaway: Factory-direct sourcing is the most efficient path to profitability.

| Aspect | Factory Direct | Reseller |

|---|---|---|

| Price | Factory Cost | Cost + 30-50% |

| Support | Technical Engineers | Sales Reps |

| Speed | Production Priority | Queue System |

Analysis: Middlemen often add cost and communication layers without adding actual value to the product.

7. Can Your Padel Court Supplier Show Past Projects?

Yes, a reliable supplier will proudly showcase a portfolio of premium court installations across diverse climates and countries. These real-world examples serve as the ultimate proof of their ability to deliver on their promises.

Global Experience

Have they installed courts in the humid heat of Florida or the freezing cold of Scandinavia? Assessing their global footprint ensures they understand the environmental challenges your specific location might face.

Verifiable References

Why does this matter? Anyone can build a website, but not everyone can build a lasting court. Ask for references from club owners who have had the courts for more than two years to verify durability.

- Diverse Climates: Weather-proof proof.

- Repeat Clients: Satisfaction proof.

Key Takeaway: A robust portfolio is the best indicator of future competence.

| Element to Check | Why It Matters |

|---|---|

| Project Age | Proves durability over time |

| Location Variety | Proves logistical capability |

| Client Type | Proves professional standards |

Analysis: Experience is the only thing that mitigates the risk of unforeseen construction issues.

8. How Does a Padel Court Supplier Calculate Costs?

Suppliers calculate costs based on a combination of raw material prices, manufacturing complexity, and logistical requirements. Understanding this breakdown helps you identify where your budget is going and where you can optimize.

The Core Components

The base price includes the steel structure, glass, turf, and lighting. Watch out for this. However, customization options like specific colors (RAL) or upgraded panoramic backs will incrementally increase the price.

Hidden Logistics Fees

Shipping heavy glass and steel across the ocean involves freight costs, customs duties, and local delivery fees. A transparent quote should separate these items clearly so you aren’t blindsided by a tax bill at the port.

- EXW vs. DDP: Know your Incoterms.

- Foundation: Usually a client cost.

Key Takeaway: Always budget for the “landed cost,” not just the factory price.

| Cost Factor | % of Budget | Variable? |

|---|---|---|

| Materials | 60% | Yes (Quality) |

| Shipping | 15% | Yes (Distance) |

| Installation | 25% | Yes (Labor) |

Analysis: Transparent pricing models prevent budget overruns and build trust between partners.

9. Will the Padel Court Supplier Help with Maintenance?

A dedicated supplier doesn’t disappear after installation; they provide comprehensive maintenance consultation and guidelines. Regular upkeep is essential to keep the warranty valid and the players safe.

Routine Check-ups

The vibration from ball impacts can loosen bolts over time. Suppliers provide checklists for tightening structural connections and checking the tension of the glass fixtures to prevent rattling or breakage.

Turf Management

Don’t ignore this. The artificial turf requires regular brushing to redistribute the silica sand. Without this, the sand clumps, the fibers wear out prematurely, and the court becomes slippery and dangerous.

- Glass Cleaning: Monthly.

- Sand Brushing: Bi-weekly.

- Bolt Tightening: Quarterly.

Key Takeaway: Proactive maintenance is the only way to protect your infrastructure investment.

| Task | Frequency | Purpose |

|---|---|---|

| Brush Turf | Every 2 Weeks | Even bounce & grip |

| Check Glass | Monthly | Prevent breakage |

| Tighten Bolts | Every 6 Months | Structural safety |

Analysis: Neglecting maintenance schedules is the fastest way to void your manufacturer’s warranty.

10. How Do You Verify a Padel Court Supplier?

Verification involves a rigorous check of the supplier’s quality certifications, factory capabilities, and financial health. You are verifying their ability to deliver a product that is safe, legal, and high-performing.

Certifications That Matter

Look for CE marking for Europe and ISO 9001 for quality management. These certificates prove that the manufacturing process adheres to strict international standards for safety and consistency.

The Factory Visit

Here is the kicker. If you can’t visit in person, request a live virtual tour. Seeing the robotic welding arms and the quality control testing lab with your own eyes is the ultimate vetting step.

- CE Marking: Safety compliance.

- ISO 9001: Quality consistency.

- FIP Standards: Sport compliance.

Key Takeaway: Due diligence is the firewall between you and a bad investment.

| Item | What to Look For |

|---|---|

| CE Certificate | Validity date & scope |

| Warranty | Coverage details (Rust/Glass) |

| Contract | Clear delivery terms |

Analysis: Certificates are the objective badge of trust in a market full of subjective claims.

Conclusion

Building a padel court is a significant capital project that requires more than just buying parts; it requires a partnership with a manufacturer who understands physics, safety, and business. From the initial showroom concept to the final bolt check, the right supplier is the linchpin of your success. By choosing a factory-direct padel court supplier, you ensure your facility is built on a foundation of quality and profitability.

Call to Action: Don’t gamble with your investment. Contact us today to get a personalized quote and see how our factory-direct solutions can bring your vision to life.

FAQ Section

Q1: Can I install the padel court myself to save money?

Answer: It is highly discouraged. Because handling 200kg glass panels and aligning steel structures requires specialized heavy equipment and laser precision; a DIY error can lead to fatal safety hazards and voided warranties.

Q2: What is the best orientation for a padel court?

Answer: North-South orientation is best. Because this prevents the sun from blinding players during the morning and evening peak hours, ensuring a better playing experience and higher booking rates.

Q3: How do I know if the steel structure is high quality?

Answer: Check the galvanization method. Because hot-dip galvanization (dipping the entire piece in molten zinc) offers far superior rust protection compared to pre-galvanized or electro-galvanized steel, especially in humid climates.

Q4: Can a padel court supplier build courts on a rooftop?

Answer: Yes, but it requires extra engineering. Because the supplier must calculate the additional wind loads at height and ensure the building’s roof structure can support the substantial weight of the steel and glass.

Q5: What is the lead time for a standard order?

Answer: Usually 20-30 days for production. Because reputable manufacturers produce courts to order to ensure the latest specs and fresh materials, though shipping times will vary depending on your distance from the factory.