Padel tennis court construction is the specialized engineering and assembly of a 200-square-meter sports facility that integrates high-impact tempered glass walls, a galvanized steel structure, and professional-grade synthetic turf. Many sports facility investors face premature structural failure, poor drainage, or safety hazards because they rely on subpar engineering standards that do not account for wind-load or soil compaction. A single hairline fracture in non-tempered glass or a sinking concrete sub-base can lead to catastrophic liability, member injuries, and thousands in lost booking revenue.

You can mitigate these risks and ensure a 20-year facility lifespan by prioritizing precision engineering and leveraging the global padel tennis court construction expertise of the SuperbPadel team. This guide explores the technical requirements and strategic decisions necessary to deliver a world-class facility. By following these rigorous standards, you protect your capital investment and ensure a premium experience for every player.

What is padel tennis court construction exactly?

Padel tennis court construction is the rigorous technical process of creating a 10×20 meter playing area enclosed by glass and mesh, specifically designed to withstand high-frequency ball impacts and player movement. You must view this process as an integrated engineering project where the padel tennis court construction depends on the perfect alignment of the foundation with the superstructure. Failing to maintain tolerances within 3mm across the entire surface can result in dead spots in ball bounce that frustrate competitive players.

The success of your facility depends on selecting the right court model, whether it is a standard, panoramic, or super panoramic design, to fit your club’s aesthetic and spectator needs. Every structural joint must be treated with anti-corrosion coatings to ensure longevity in humid or outdoor environments. By following international standards, you guarantee a professional environment that attracts elite tournaments and high-paying members.

What are the core components?

The core components of a padel court consist of the concrete sub-base, a hot-dip galvanized steel frame, 10mm to 12mm tempered safety glass, and a specialized synthetic turf system. Here is the deal: if any of these elements are low-quality, the entire project’s safety and playability are compromised.

- Structural Steel: Modular frames with 80x80mm or 100x100mm profiles.

- Enclosure Glass: EN 12150-compliant tempered panels for maximum impact resistance.

- Synthetic Turf: Fibrillated or monofilament polyethylene fibers with sand infill.

- Lighting System: 4 to 8 LED floodlights providing 300 to 500 lux levels.

Why is precision engineering needed?

Precision engineering ensures that the structural cage and glass panels interact safely during high-intensity play while resisting environmental stresses like wind and thermal expansion. You cannot afford to ignore the physics of wind-load, especially for outdoor courts where the glass acts as a massive sail.

- Bolt Torque Specs: Essential for preventing structural vibration and loosening over time.

- Glass Alignment: Precision spacing prevents glass-on-steel contact that causes shattering.

- Foundation Leveling: A slope of less than 0.5% is mandatory for proper drainage and bounce.

- Vertical Tolerance: Frames must be perfectly perpendicular to support the weight of the glass.

How does it differ from tennis builds?

Padel court construction differs from tennis in its reliance on vertical enclosures and a much smaller, high-density footprint that maximizes player capacity per square meter. Make no mistake, while a tennis court is a simple flat surface, a padel court is a complex 3D structure that requires specialized anchorage.

- Spatial Efficiency: Three padel courts can fit into the space of a single tennis court.

- Vertical Play: The walls are active parts of the game, requiring specific rebound testing.

- Foundation Depth: Padel requires reinforced concrete perimeter beams to secure the glass cage.

- Surface Friction: Padel turf requires lower pile height and specific sand density for sliding.

Key Takeaway: Understanding the technical complexity of padel components is the first step toward building a durable, high-performance facility that meets international standards.

| Feature | Padel Court | Tennis Court |

|---|---|---|

| Dimensions | 10m x 20m | 10.97m x 23.77m |

| Enclosure | Glass and Metallic Mesh | None (or simple fencing) |

| Surface | Synthetic Turf with Sand | Hard Court, Clay, or Grass |

| Players | 4 (Doubles focus) | 2 or 4 |

| Playable Walls | Yes (Strategic use) | No |

Analysis of Padel vs. Tennis Specs: The high density of players per square foot in padel significantly improves your revenue-to-space ratio. While the initial engineering of a padel court is more complex due to the glass and steel requirements, the commercial throughput is nearly triple that of a traditional tennis court. This makes it a superior investment for urban sports clubs looking to maximize land utility.

Is padel tennis court construction worth the investment?

Padel tennis court construction is widely considered a high-yield investment because it provides a rapid return on capital through high booking frequency and lower land requirements. You will find that the social nature of the sport drives consistent member engagement, leading to secondary revenue from food, beverage, and pro-shop sales. In many markets, a well-managed padel facility can achieve full capital recoupment in as little as 18 to 24 months.

Investors are increasingly turning to padel because it attracts a diverse demographic, from corporate professionals to families, ensuring high court occupancy during off-peak hours. The modular nature of modern court designs also means you can scale your facility as demand grows without major structural overhauls. By focusing on quality construction, you minimize future maintenance costs and maximize the resale value of the sports asset.

What is the average ROI?

The average return on investment for a commercial padel court typically ranges from 30% to 50% annually, depending on your local booking rates and operational efficiency. Believe it or not, the utilization rate of padel courts often exceeds 70% in urban centers due to the sport’s high popularity.

- Hourly Rates: Typically between $40 and $100 depending on the region and time.

- Occupancy Hours: Prime time usually runs from 6:00 PM to 11:00 PM daily.

- Operating Costs: Minimal staffing required with automated booking and lighting systems.

- Ancillary Income: Coaching, tournaments, and racket rentals provide significant upside.

Do courts increase property value?

Integrating padel courts into real estate developments or hotels significantly increases property value by offering a modern, high-demand amenity that sets the project apart. You should consider padel as a “lifestyle anchor” that attracts high-net-worth residents or guests who prioritize fitness and social interaction.

- Aesthetic Appeal: Modern panoramic designs enhance the architectural profile of a facility.

- Market Differentiation: Properties with padel courts command higher rental and sale premiums.

- Community Building: Courts serve as a hub for social networking within residential complexes.

- Space Optimization: Converting underutilized parking or rooftops into courts maximizes land value.

How many players per hour are needed?

To maintain a healthy profit margin, you should aim for at least four players per court per hour, which is the standard format for doubles-focused padel matches. But here is the kicker: because the game is easy to learn, your potential player pool is much larger than that of tennis or squash.

- Doubles Format: Four players sharing the cost makes it affordable and social.

- Turnover Rate: 60 to 90-minute sessions allow for high daily throughput.

- Member Retention: The social aspect leads to recurring weekly bookings.

- League Play: Organized ladders ensure courts are filled during weekdays.

Key Takeaway: Padel is a commercially superior sports asset that offers faster ROI and higher social engagement than almost any other recreational facility.

| Revenue Stream | Estimated Monthly Income | Notes |

|---|---|---|

| Court Bookings | $6,000 – $12,000 | Based on 10 hours/day at $40/hour |

| Pro-Shop/Rentals | $800 – $1,500 | Rackets, balls, and grip tape sales |

| Coaching/Clinics | $1,200 – $2,500 | 10% – 20% commission on pro fees |

| Sponsorships | $500 – $1,500 | Local brand placement on glass/mesh |

| Total Per Court | $8,500 – $17,500 | Gross monthly potential |

Analysis of Revenue Projections: The data indicates that court bookings remain the primary driver of income, but secondary streams like coaching can cover nearly all monthly utility costs. By building high-quality courts that attract competitive play, you unlock the ability to host sponsored tournaments. These events can add significant lump-sum revenue to your annual balance sheet while increasing club visibility.

Which permits affect padel tennis court construction?

Padel tennis court construction requires a variety of local permits including zoning clearances, structural engineering certifications, and noise impact assessments to ensure legal compliance. You must verify the specific classification of your project, as some jurisdictions treat padel courts as temporary modular structures while others view them as permanent buildings. Utilizing a proven padel tennis court construction blueprint can help you provide local authorities with the technical documentation needed to expedite approval.

Failing to secure the correct permits can lead to costly work-stoppages or even the forced removal of the facility. You should engage a local architect or consultant early in the planning phase to navigate setbacks and height restrictions that might apply to your specific plot. Professional builders will often provide the structural calculations for wind-load and soil bearing capacity that your local planning office will require.

Are zoning laws different for padel?

Zoning laws for padel often focus on land use categories, specifically whether a property is zoned for commercial recreation, residential amenities, or agricultural use. You will find that some regions have strict “open space” requirements that may limit where you can pour a concrete sub-base.

- Setback Requirements: Distance required between the court and property lines.

- Height Restrictions: Important for lighting poles and panoramic glass structures.

- Impermeable Surface Limits: Regulations regarding how much land can be covered in concrete.

- Use Permits: Necessary for operating a commercial business in specific zones.

How do I get safety certificates?

Safety certificates are obtained through third-party engineering inspections that verify the glass tempering quality, structural weld integrity, and electrical safety of the lighting. This is not just a formality; it is your primary defense against future liability claims.

- EN 12150 Compliance: European standard for tempered safety glass.

- Soil Compaction Testing: Confirms the ground can support the weight without shifting.

- Wind-Load Certification: Essential for outdoor courts in hurricane or high-wind zones.

- Lighting Safety: Ensuring IP66 waterproof ratings for all outdoor electrical components.

What are the noise regulation standards?

Noise regulation standards involve measuring the decibel levels of ball-on-glass impacts and player voices to ensure the facility does not disturb neighboring residential areas. But here is the real story: acoustic panels or plexiglass barriers may be required if your court is located within 50 meters of residential windows.

- Decibel Limits: Typically 55dB during the day and 45dB at night in residential zones.

- Acoustic Buffers: Landscaping or sound-dampening mesh can mitigate noise.

- Operating Hours: Restrictions on late-night play to maintain local harmony.

- Impact Vibration: Proper sub-base isolation prevents sound traveling through the ground.

Key Takeaway: Proactive permit management and technical documentation are essential to avoid legal delays and ensure your facility is fully compliant with local safety and zoning laws.

| Permit Type | Critical Documentation | Typical Timeline |

|---|---|---|

| Zoning/Land Use | Site plans, topographical maps | 4 – 12 Weeks |

| Structural/Building | Engineering drawings, load calcs | 2 – 8 Weeks |

| Environmental | Drainage plans, soil reports | 3 – 6 Weeks |

| Electrical | Circuit diagrams, lux level plans | 1 – 3 Weeks |

| Occupancy | Final safety inspection reports | 1 Week |

Analysis of Regulatory Checklists: The zoning and structural phases are the most time-intensive and require the most detailed technical input from your manufacturer. By providing the local authorities with pre-certified structural drawings from a reputable padel manufacturer, you can often cut the approval time for building permits by 30%. This efficiency allows you to break ground sooner and begin generating revenue.

How does ground prep impact padel tennis court construction?

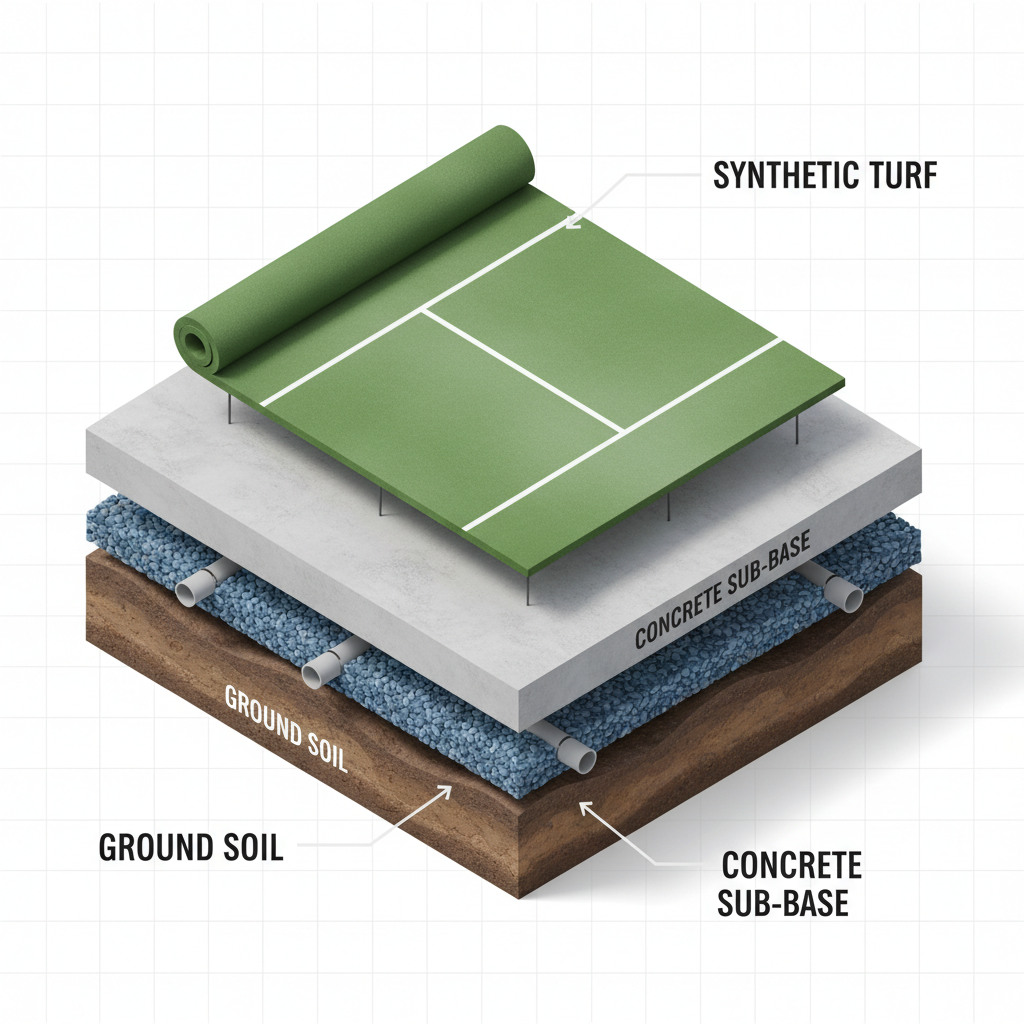

Ground preparation is the most critical phase of padel tennis court construction because any instability in the sub-base will lead to surface cracking and glass misalignment. You must ensure that the soil is properly excavated and compacted to a minimum of 95% Modified Proctor density to prevent the court from settling. A technical padel tennis court construction cross-section reveals that the layers of gravel and concrete must be perfectly leveled.

If you ignore the soil conditions, such as high clay content or poor drainage, water will accumulate under the slab, causing it to heave or crack. This stage requires heavy machinery and laser-leveling tools to achieve the precision required for a professional playing surface. Investing heavily in ground preparation is essentially “insurance” for the high-value glass and steel structure that sits on top of it.

Is a concrete slab required?

A reinforced concrete slab, typically 15cm to 20cm thick, is the industry standard for padel courts because it provides the necessary weight and stability. Here is the kicker: while porous asphalt is an alternative, it lacks the compressive strength required for long-term glass stability in high-traffic clubs.

- Reinforcement: Steel mesh or rebar is essential to prevent shrinkage cracks.

- Curing Time: Concrete must cure for at least 21 days before turf installation.

- Surface Finish: A smooth, helicopter-finish is required for optimal turf adhesion.

- Expansion Joints: Strategically placed to prevent large-scale cracking during temperature changes.

How to ensure a perfectly level base?

Ensuring a perfectly level base requires the use of laser-guided grading equipment during the gravel compaction and concrete pouring stages. Believe it or not, even a 1% deviation in level can cause water to pool on the court, significantly shortening the lifespan of your synthetic turf.

- Laser Leveling: Tools that provide real-time feedback during the pour.

- Formwork Precision: Ensuring the perimeter beams are exactly 10m x 20m.

- Grading Gradients: A slight slope (0.5%) is often used for outdoor drainage.

- Flatness Testing: Using a 3-meter straight edge to check for dips and humps.

What foundation depth is necessary?

The required foundation depth depends on your local frost line and soil bearing capacity, but a standard padel perimeter beam usually extends 40cm to 60cm deep. Make no mistake, the perimeter beam is what actually holds the court together, acting as the anchor point for the steel uprights.

- Perimeter Beams: Reinforced concrete footings under the glass and mesh walls.

- Frost Line Considerations: Foundations must go below the freeze-thaw depth in cold climates.

- Soil Replacement: Removing organic matter and replacing it with non-expansive fill.

- Anchorage Points: Heavy-duty bolts embedded directly into the concrete beam.

Key Takeaway: The longevity of your court is directly proportional to the quality of your groundwork; never compromise on soil compaction or concrete reinforcement.

| Foundation Layer | Material Specification | Purpose |

|---|---|---|

| Sub-Grade | Compacted native soil | Load-bearing base |

| Sub-Base | 15cm-20cm Crushed stone | Drainage and stability |

| Vapor Barrier | Polyethylene sheeting | Prevents moisture migration |

| Slab | 15cm Reinforced concrete | Main playing surface |

| Perimeter Beam | 40cm x 40cm Reinforced concrete | Structural anchoring |

Analysis of Soil Compression Standards: Using a crushed stone sub-base between the native soil and the concrete slab is non-negotiable for professional builds. This layer acts as a capillary break and a drainage plenum, ensuring that even during heavy rains, the pressure under the slab remains equalized. Without this layer, your concrete is at a high risk of cracking due to hydrostatic pressure from the ground.

What materials define padel tennis court construction?

Padel tennis court construction is defined by the use of high-strength industrial materials, specifically hot-dip galvanized steel, tempered safety glass, and monofilament synthetic turf. You must choose materials that are rated for high-frequency impact, as the unique nature of padel involves constant striking of the enclosures. A premium padel tennis court construction utilizes a galvanized Padel Structure that resists oxidation, ensuring the court remains structurally sound for decades.

Selecting inferior materials, such as non-galvanized steel or thin glass, will lead to rust and breakage, creating significant safety risks. Quality materials also impact the “feel” of the game; professional players demand a consistent ball rebound from the glass and a specific level of grip from the turf. By investing in European-standard materials, you position your club as a premier destination for serious athletes.

Why choose tempered safety glass?

Tempered safety glass is chosen for its incredible strength and its ability to shatter into small, blunt pieces if broken, minimizing the risk of injury. But here is the real story: the glass thickness (10mm or 12mm) dictates the rebound consistency and the overall structural rigidity of the panoramic walls.

- Impact Resistance: 5x stronger than standard annealed glass.

- Thermal Stability: Withstands extreme temperature fluctuations without cracking.

- Clarity: Provides a high-definition viewing experience for spectators.

- Certification: Must meet EN 12150 or similar global safety standards.

Which turf fiber provides best bounce?

The best ball bounce and player comfort are provided by monofilament polyethylene fibers, which are more durable than cheaper fibrillated options. You will find that “texturized” or “curly” turf is increasingly popular because it holds the sand infill more effectively, reducing maintenance and surface migration.

- Pile Height: Typically 10mm to 12mm for professional padel.

- Stitch Density: High-density turf (over 50,000 stitches/m2) offers better wear resistance.

- Sand Infill: Kiln-dried silica sand (0.3-0.8mm) ensures a consistent surface.

- UV Stabilization: Prevents the turf from fading and becoming brittle in the sun.

How does galvanization prevent rust?

Galvanization prevents rust by coating the steel structure in a protective layer of zinc, which acts as a sacrificial anode even if the surface is scratched. Here is the kicker: for outdoor or coastal courts, “hot-dip” galvanization is mandatory to prevent salt-air corrosion from destroying the frame.

- Zinc Thickness: Measured in microns; higher thickness equals longer protection.

- Internal Protection: Hot-dipping coats the inside of hollow steel profiles.

- Powder Coating: An additional layer of electrostatic paint for color and extra protection.

- Longevity: Increases the structural lifespan from 5 years to over 20 years.

Key Takeaway: High-quality materials like 12mm tempered glass and hot-dip galvanized steel are non-negotiable for safety, performance, and long-term ROI.

| Component | Standard Quality | Premium Quality | Expected Life |

|---|---|---|---|

| Glass | 10mm Tempered | 12mm Tempered | 20+ Years |

| Steel | Electro-galvanized | Hot-dip Galvanized | 15-20 Years |

| Turf | Fibrillated PE | Monofilament PE | 5-8 Years |

| Lighting | 200W LED | 300W High-Efficiency LED | 50,000 Hours |

| Mesh | Electro-welded | Anti-injury Folded Mesh | 15 Years |

Analysis of Material Longevity: While premium materials increase the upfront cost by approximately 15%, they reduce long-term maintenance and replacement costs by over 50%. For example, monofilament turf not only lasts longer but also provides a superior playing experience that allows you to charge higher booking fees. This effectively pays for the material upgrade within the first year of operation.

How long does padel tennis court construction take?

Padel tennis court construction typically takes between 4 to 8 weeks, depending on site conditions, weather, and the complexity of the groundwork required. You should plan for a phased approach where the foundation is completed first, followed by a curing period for the concrete before the superstructure is assembled. The actual padel tennis court construction of the steel cage and glass can be completed in as little as 5 to 7 days.

Delays often occur during the permitting phase or due to unexpected soil issues like underground utilities or high water tables. You can accelerate the timeline by choosing a manufacturer that offers pre-engineered modular components that bolt together quickly on-site. Managing the logistics of glass delivery is also critical, as these panels require specialized handling equipment to avoid mid-project breakages.

What is the site preparation timeline?

Site preparation usually takes 2 to 3 weeks and includes excavation, drainage installation, and the pouring of the reinforced concrete slab. Here is the deal: you cannot rush the concrete curing process, as installing turf on “green” concrete will lead to adhesive failure and moisture bubbles.

- Excavation: 2-4 days depending on soil type and machinery.

- Formwork & Rebar: 3 days for precise alignment and reinforcement.

- Concrete Pour: 1 day, followed by a 21-day curing period.

- Leveling Check: 1 day after curing to ensure a 3mm tolerance.

When is the optimal time for glass install?

The optimal time for glass installation is during the final assembly phase, once the steel structure is fully anchored and the lighting system is in place. You must wait for a calm day with low wind, as maneuvering 200kg glass panels becomes dangerous in gusty conditions.

- Structural Integrity Check: Ensure all bolts are torqued before glass arrives.

- Placement Timing: Glass should be installed before the turf to prevent sand contamination.

- Handling Equipment: Use suction-cup lifters and mini-cranes for precision.

- Safety Perimeter: Clear the site of non-essential personnel during this phase.

Weather-related delays are managed by building flexibility into your schedule and prioritizing indoor groundwork during rainy seasons if possible. Make no mistake, pouring concrete or gluing synthetic turf during a rainstorm will lead to a total failure of the surface.

- Rain Protection: Use heavy-duty tarps to keep the sub-base dry.

- Wind Monitoring: Stop all high-altitude lighting and glass work if winds exceed 30km/h.

- Temperature Control: Avoid gluing turf if the ground temperature is below 10°C.

- Project Buffering: Always add a 20% “weather buffer” to your public opening date.

Key Takeaway: A structured timeline with built-in curing and weather buffers is essential for a high-quality build and a stress-free project management experience.

| Phase | Duration | Primary Tasks |

|---|---|---|

| Permits & Design | 4 – 8 Weeks | Zoning, engineering, and architectural approvals |

| Ground Preparation | 2 – 3 Weeks | Excavation, leveling, and drainage |

| Foundation Curing | 3 Weeks | Allowing concrete to reach full strength |

| Superstructure | 1 Week | Steel cage assembly and lighting install |

| Glass & Turf | 1 Week | Glass placement, turf gluing, and sand infill |

Analysis of the Construction Timeline: The most critical “dead time” is the concrete curing phase. You can utilize this three-week window to finalize your marketing strategy, hire staff, and set up your digital booking system. By synchronizing the arrival of the modular court components with the end of the curing period, you ensure that the final assembly begins immediately.

Why is drainage vital in padel tennis court construction?

Drainage is vital in padel tennis court construction because water accumulation prevents play and can cause the synthetic turf fibers to rot and the adhesive to fail. You must design the sub-base with a slight gradient or utilize porous materials to ensure that even heavy rainfall is cleared in minutes. High-quality padel tennis court construction relies on Padel Grass that features built-in drainage holes to allow water to pass through.

In outdoor facilities, poor drainage is the leading cause of “dead spots” where the ball does not bounce correctly due to moisture trapped in the sand. Furthermore, standing water around the steel structure can accelerate corrosion, even on galvanized frames. A well-engineered drainage system is the difference between a facility that operates 365 days a year and one frequently closed by rain.

What is a porous sub-base?

A porous sub-base is an engineering design that uses no-fines concrete or specialized asphalt to allow water to drain vertically through the slab. Believe it or not, this system allows a padel court to be playable within 15 minutes of a heavy tropical downpour.

- Vertical Drainage: Eliminates the need for surface slopes.

- Material Choice: Open-graded aggregates mixed with a cement binder.

- Maintenance: Requires periodic pressure washing to prevent pore clogging.

- Cost: Higher upfront cost than standard concrete but offers superior uptime.

How to manage heavy rainfall runoff?

Managing heavy rainfall runoff involves installing perimeter drains and ensuring the surrounding landscape is graded away from the courts. You should consider the “catchment area” of your facility; a block of four courts generates massive water volume that must be redirected safely.

- Perimeter Channels: Hidden gutters that collect water from the court edges.

- French Drains: Gravel-filled trenches that redirect water to a soakaway.

- Slope Design: A 0.5% to 1.0% slope toward the long sides of the court.

- Retention Ponds: Necessary for large clubs to meet local environmental codes.

Does turf impact drainage speed?

Turf impacts drainage speed significantly through its backing permeability and the type of sand infill used to weigh it down. But here is the kicker: if you use sand with too many “fines” or dust, it will create a muddy sludge that blocks the drainage holes.

- Drainage Holes: Standard turf has holes every 10cm to 15cm for water exit.

- Sand Quality: Silica sand must be washed and graded to prevent clogging.

- Turf Backing: Latex or polyurethane backings offer different levels of water resistance.

- Infill Depth: Correct sand volume ensures the turf stays open for water flow.

Key Takeaway: Investing in advanced drainage solutions like porous slabs or precision gradients is the only way to guarantee year-round court availability and revenue.

| Drainage Method | Cost Level | Playability After Rain | Maintenance Needs |

|---|---|---|---|

| Surface Gradient | Low | 45 – 60 Minutes | Low |

| Porous Concrete | High | 10 – 15 Minutes | Moderate (Cleaning) |

| Perimeter Drains | Moderate | 30 – 45 Minutes | Moderate (Debris) |

| No-Fines Base | High | 5 – 10 Minutes | High (Clogging risk) |

Analysis of Water Discharge Ratings: For commercial clubs, the “Time to Playable” metric is the most important drainage statistic. A porous concrete system can increase your annual billable hours by 10% to 15% in rainy climates. By ensuring water is discharged rapidly, you also protect the synthetic turf from mold and algae growth, which are the primary causes of surface degradation.

Can DIY beat pro padel tennis court construction?

Professional padel tennis court construction almost always outperforms DIY attempts because of the specialized equipment and engineering precision required to handle 200kg glass panels. You might save money on labor initially, but the risk of structural misalignment or glass breakage can triple your total project cost. Expert padel tennis court construction teams bring laser-leveling tools and calibrated torque wrenches to every build.

The most common DIY failures involve poor foundation leveling and improper glass-to-metal spacing, which causes the glass to explode due to structural vibration. Furthermore, professional builders provide warranties that protect your investment against manufacturing defects or assembly errors. In the commercial world, the liability of an amateur-built court failing and injuring a player is a risk that outweighs any savings.

What are common rookie errors?

The most common rookie errors include inadequate soil compaction, improper curing of the concrete slab, and using the wrong type of sand for the turf. Believe it or not, using standard beach sand instead of graded silica sand will destroy the turf fibers within months due to its abrasive nature.

- Over-Torquing Bolts: Can snap galvanized coatings and lead to internal rust.

- Uneven Slab: Creates water pooling and inconsistent ball bounce.

- Poor Glass Alignment: Leading to structural stress and eventual shattering.

- Incorrect Net Tensioning: Affecting the professional feel and playability of the court.

Is professional assembly safer?

Professional assembly is significantly safer because it utilizes specialized glass suction lifters, scaffolding, and cranes that are operated by trained crews. You should understand that handling 12mm tempered glass is a high-risk activity; one wrong move can result in the entire panel disintegrating into shards.

- Certified Equipment: Calibrated tools for structural integrity.

- Safety Protocols: Proper use of harnesses and glass handling gear.

- Experience: Recognition of structural “red flags” before they become failures.

- Insurance: Pro builders carry liability insurance that covers the construction site.

When should I hire a lead engineer?

You should hire a lead engineer for the design and foundation phases, especially if your court is being built on challenging terrain or in high-wind zones. But here is the real story: an engineer can provide the structural calculations required by your insurance provider to cover the facility.

- Wind-Load Calcs: Essential for ensuring the panoramic glass doesn’t fail.

- Soil Reports: Determining the exact depth and reinforcement of the foundation.

- Electrical Oversight: Ensuring the high-output LED system is safely grounded.

- Quality Control: Signing off on the structural integrity of the build before opening.

Key Takeaway: While DIY might seem cost-effective, the safety risks and potential for technical failure make professional construction the only viable path for commercial facilities.

| Risk Factor | DIY Installation | Professional Build |

|---|---|---|

| Glass Breakage | High Risk (Manual handling) | Low Risk (Mechanical lifters) |

| Structural Warranty | None (Voided on components) | 10 – 20 Year Guarantee |

| Playability | Variable (Prone to dead spots) | Certified (ITF Standards) |

| Safety Liability | High (Owner assumes all risk) | Low (Contractor insured) |

| Completion Time | 3 – 6 Months | 4 – 8 Weeks |

Analysis of DIY Risk vs. Pro Reward: The financial “savings” of a DIY build are often negated by the first structural error. If a single glass panel breaks during a DIY install, you will lose significant material cost and weeks in shipping time. Professional crews install these courts daily and have established protocols to handle every technical challenge, ensuring your club opens on time.

What determines padel tennis court construction costs?

Padel tennis court construction costs are primarily determined by the quality of materials, the court design (standard vs. panoramic), and the logistics of shipping. You will find that a premium padel tennis court construction using a Panoramic Padel Court design costs more due to the thicker glass and reinforced steel. On average, a professional-grade court costs between $20,000 and $35,000 for materials alone.

Secondary cost drivers include the type of lighting and the quality of the synthetic turf. While it is tempting to choose the lowest quote, you must account for “hidden” costs like port fees, inland transport, and specialized tools. By buying directly from a manufacturer, you can save up to 30% by eliminating middleman markups while maintaining high material standards.

How do logistics impact the price?

Logistics impact the price significantly, as a single padel court requires a 20ft or 40ft shipping container to transport the heavy steel and fragile glass. Here is the deal: if you are located far from a major port, the “inland drayage” costs can add thousands of dollars to your final bill.

- Container Fees: Fluctuating global shipping rates based on seasonal demand.

- Import Duties: Varying taxes based on your country’s trade agreements.

- Storage Fees: Costs incurred if the site isn’t ready for unloading upon arrival.

- Unloading Equipment: Hiring cranes or forklifts to empty the container safely.

Does customization add significant cost?

Customization, such as specific RAL colors for the steel or branded logos on the turf, adds a moderate premium but offers high marketing value. You should view customization as an investment in your brand identity that makes your facility more “Instagrammable” and recognizable to potential members.

- RAL Colors: Custom powder coating for the structural cage.

- Turf Branding: Integrating logos into the synthetic grass during manufacturing.

- Specialized Lighting: Upgrading to smart LED systems with remote controls.

- Net Customization: Printing club names or sponsor logos on the net band.

Hidden maintenance fees include the periodic addition of silica sand, cleaning of the glass walls, and the replacement of lighting components. But here is the kicker: if you build with low-quality materials, your “hidden” fees will actually be major repair costs like fixing rusted joints or faded turf.

- Sand Top-Up: Typically required every 6 to 12 months for high-traffic courts.

- Glass Cleaning: Professional cleaning needed to maintain transparency and hygiene.

- Structural Inspections: Annual checks to ensure bolt tension and weld integrity.

- Lighting Replacement: LED drivers may need replacement every 5 to 7 years.

Key Takeaway: Focus on the “Total Cost of Ownership” rather than just the initial quote; high-quality materials reduce the long-term financial burden.

| Expense Category | Estimated % of Total Cost | Typical Range (USD) |

|---|---|---|

| Material (Court Kit) | 40% – 50% | $18,000 – $30,000 |

| Groundwork/Foundation | 20% – 30% | $8,000 – $15,000 |

| Shipping/Logistics | 10% – 15% | $2,000 – $5,000 |

| Installation Labor | 10% – 15% | $4,000 – $7,000 |

| Permits/Consulting | 5% | $1,000 – $3,000 |

Analysis of Cost Allocation Breakdown: The material kit and groundwork represent the bulk of your investment. Reducing spend on the kit often results in a shorter facility lifespan, while cutting corners on groundwork leads to structural failure. Buying factory-direct protects the quality of the core components while reducing the non-value-added logistics spend, keeping your total budget efficient.

How to maintain padel tennis court construction quality?

Maintaining padel tennis court construction quality requires a consistent schedule of turf brushing, glass cleaning, and structural bolt inspections. You must realize that even the best-built court will degrade if the silica sand infill is not evenly distributed or if drainage holes become clogged. Regular maintenance ensures that your padel tennis court construction investment continues to generate revenue for another 15 to 20 years.

Neglecting maintenance can lead to slippery surfaces, poor ball bounce, and “cloudy” glass that diminishes the player experience. You should implement a digital maintenance log to track weekly tasks and annual structural sign-offs. For large clubs, investing in professional turf grooming machinery can save hundreds of hours of manual labor and ensure a perfectly consistent playing surface.

How often should I brush the turf?

You should brush the turf at least once a week for high-traffic courts to ensure the sand infill is evenly distributed and fibers remain upright. Believe it or not, allowing the sand to migrate to the corners creates slippery “bald spots” that can cause player slips and falls.

- Brushing Pattern: Use a circular or “cross-hatch” pattern to redistribute sand.

- Equipment: Use a specialized triangular brush or a motorized grooming machine.

- Sand Level Check: Ensure the infill is within 2mm of the fiber tips.

- Debris Removal: Always remove leaves and trash before brushing to prevent clogging.

When is the structural inspection due?

A comprehensive structural inspection is due every 12 months, with monthly visual checks for loose bolts or signs of rust. This is where it gets interesting: the vibration from thousands of ball-impacts can slowly loosen the glass-mounting hardware, creating a potential safety hazard if left unchecked.

- Bolt Tensioning: Check all primary structural bolts and glass clips.

- Glass Edge Check: Ensure the protective gaskets are still in place and supple.

- Anchor Bolts: Verify that the foundation bolts are not loosening from the concrete.

- Weld Integrity: Look for hairline cracks in the paint that might indicate structural stress.

How to clean high-impact glass walls?

Cleaning high-impact glass walls involves using non-abrasive detergents and squeegees to remove sweat, handprints, and environmental dust. But here is the kicker: you must avoid using harsh chemical solvents that can degrade the structural silicone or the gaskets that hold the glass in place.

- Frequency: Weekly for interior handprints; monthly for exterior dust.

- Water Source: Use deionized or soft water to prevent hard-water spotting.

- Gasket Care: Avoid high-pressure washers near the glass-to-steel joints.

- Visibility: Clean glass is essential for spectator enjoyment and broadcast quality.

Key Takeaway: A proactive maintenance schedule is the only way to protect your ROI and ensure your facility remains a premium destination for years to come.

| Task | Frequency | Estimated Time | Tool Required |

|---|---|---|---|

| Turf Brushing | Weekly | 30 Minutes | Triangular Brush |

| Glass Cleaning | Bi-Weekly | 45 Minutes | Squeegee & Soft Water |

| Sand Distribution | Monthly | 1 Hour | Grooming Machine |

| Bolt Inspection | Quarterly | 1 Hour | Torque Wrench |

| Full Structural Audit | Annual | 4 Hours | Professional Engineer |

Analysis of the Maintenance Calendar: Most maintenance tasks are simple but require consistency. By dedicating just two hours a week to court care, you can extend the life of your synthetic turf by up to three years. This equates to a significant financial saving, as turf replacement is the most frequent and expensive recurring cost in padel facility management over a ten-year cycle.

The long-term durability of your sports facility depends entirely on the integrity of the initial build and the materials you select today. By adhering to the technical standards and maintenance protocols outlined in this guide, you mitigate the risks of structural decay and maximize player satisfaction. To explore custom designs or request a technical consultation for your project, contact us today and let our engineers bring your vision to life.

*

5 FAQs About Padel Court Construction

- Can I build a padel court on an existing asphalt surface?

While possible, asphalt requires specific structural reinforcement and precise leveling to prevent the “hollow” bounce effect. You must ensure the asphalt is thick enough (minimum 10-12cm) to support the heavy glass-mounting anchors without cracking or shifting under the weight of the steel cage. - What is the minimum clearance needed around the court?

Safety regulations typically require at least 0.5 to 1.0 meters of clearance beyond the glass walls for maintenance and spectator movement. For indoor facilities, the minimum ceiling height should be 6 meters, though 8 to 10 meters is preferred to accommodate high lobs in professional play. - How long is the warranty on the steel structure?

High-performance manufacturers offer a 20-year design life warranty on hot-dip galvanized frames. This covers structural integrity and resistance to rust, provided the court is maintained according to guidelines. Always verify that your manufacturer uses certified hot-dip processes rather than simple electro-plating. - Can I customize the court colors to match my brand?

Yes, structural frames can be powder-coated in any RAL color, and synthetic turf is available in various shades like blue, green, and clay-red. You can also integrate high-visibility logos into the turf or net band, which is a popular way to attract local sponsorships and increase brand recognition. - What is the typical ROI timeframe for a commercial club?

Depending on your location and booking rates, most facilities achieve full capital recoupment within 18 to 24 months. The high occupancy rates of padel (often over 70%) and the social nature of the sport drive much faster returns than traditional tennis or squash facilities, especially in urban environments.